Novel high-speed rail axle power bearing

A high-speed, high-speed technology, used in shafts and bearings, bearing components, rolling resistance optimization, etc., can solve problems such as unsupported running speed, raceway indentation, roller skew, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

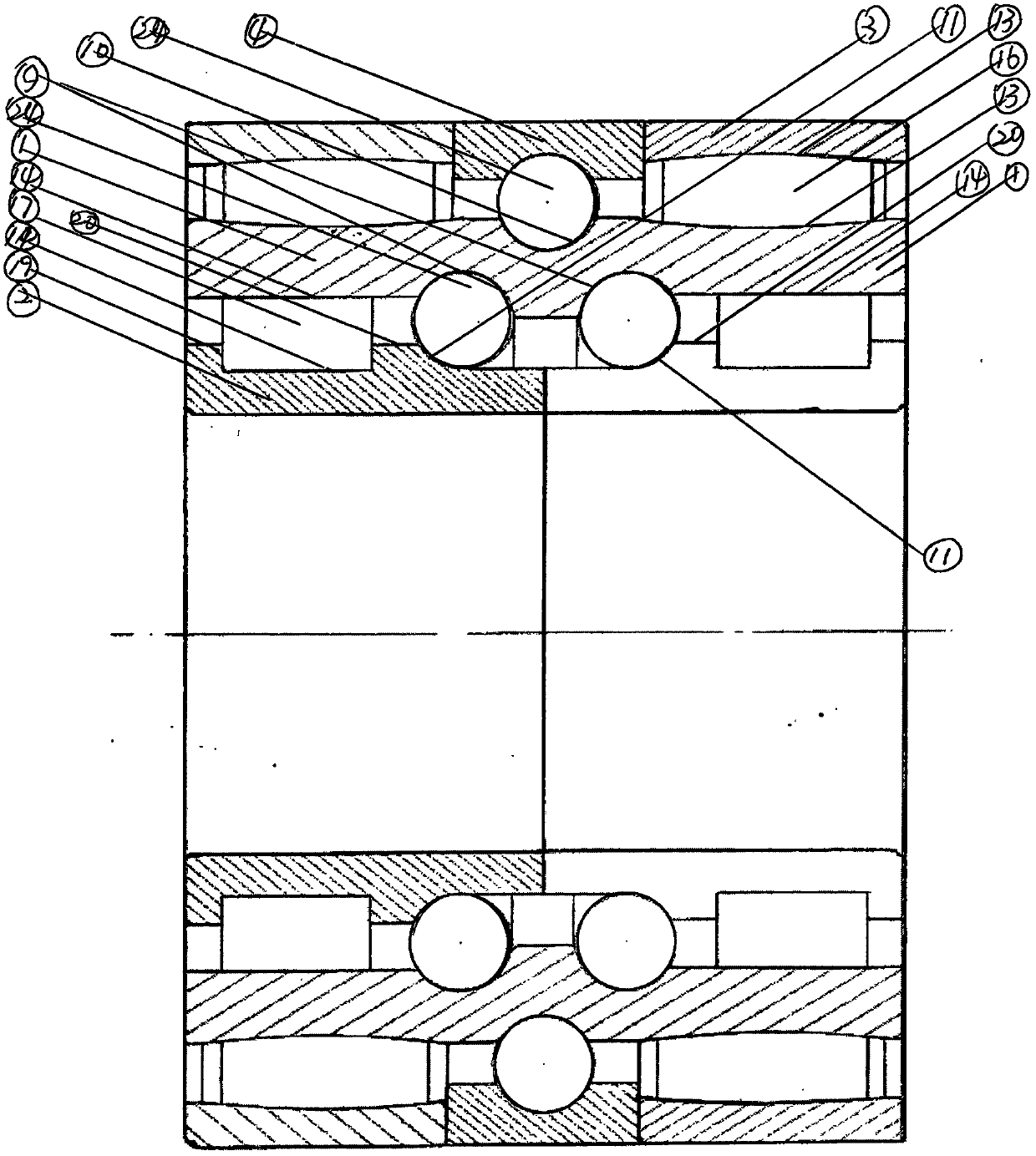

Embodiment 1

[0063] Such as figure 1 The "new high-speed high-speed rail axle dynamic bearing" shown includes: a variable-diameter middle ring 1, two double-half inner rings 2, two double-half outer rings 3, a deep groove ball bearing outer ring 4 and inner and outer rings. There are two layers of rolling elements; two rings of double-row angular contact spherical rolling element track 9 are arranged at the middle distance of the axial distance of the inner circumference of the variable-diameter middle ring 1, and one ring is arranged at the middle of the axial distance of the outer circumference of the variable-diameter middle ring 1 The deep groove spherical rolling element track 10, the deep groove spherical rolling element raceway 10 is arranged between the two turns of the double row angular contact spherical rolling element track 9 set in the middle of the inner circumference of the relative variable diameter middle ring 1, forming a variable diameter center ring, in the double-row a...

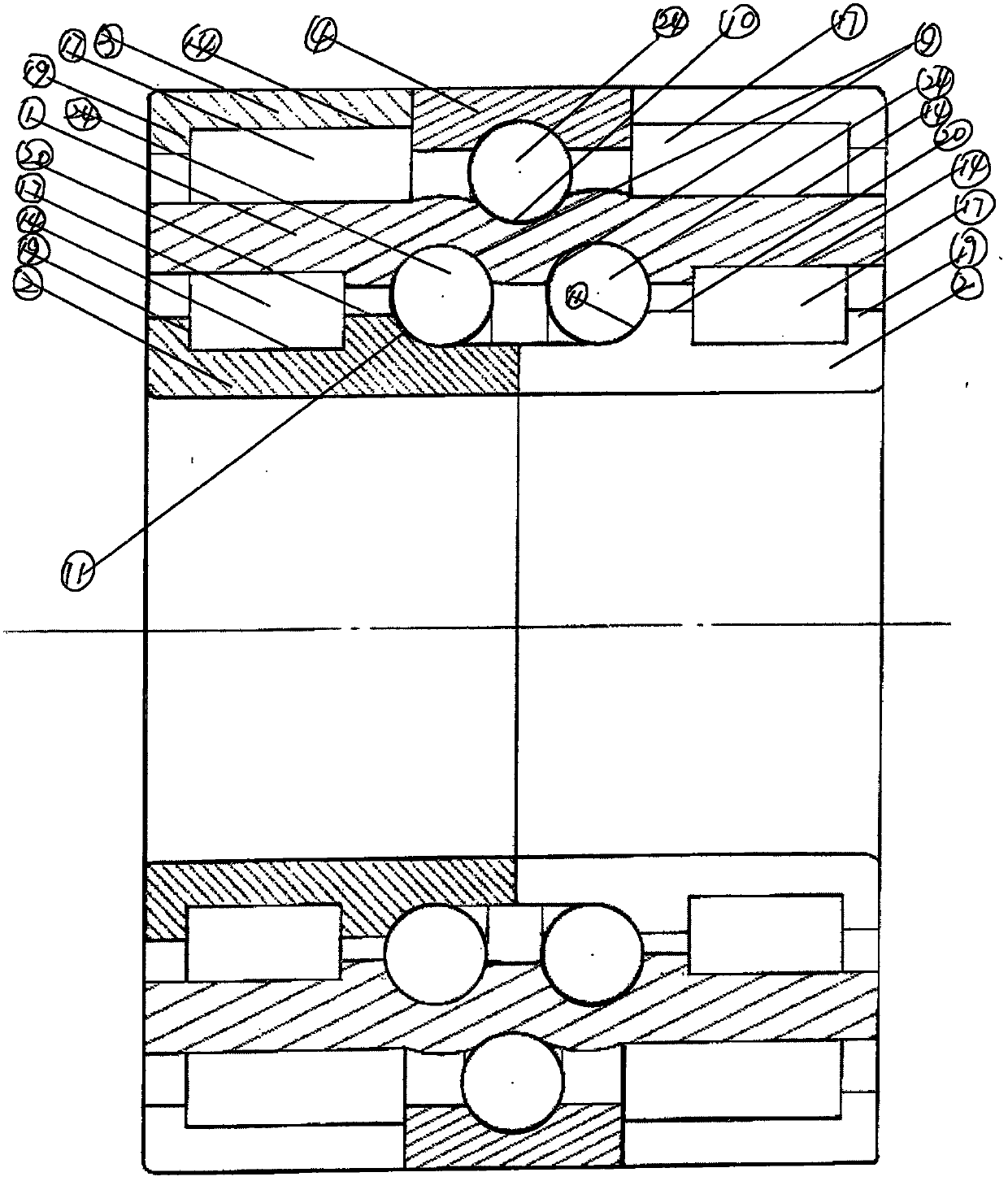

Embodiment 2

[0068] Such as figure 2 The "new high-speed high-speed rail axle dynamic bearing" shown includes: a variable-diameter middle ring, two double-half inner rings 2, two double-half outer rings 3, a deep groove ball bearing outer ring 4 and inner and outer two Two layers of rolling elements; the distance between the middle part of the axial distance of the inner circumference of the variable-diameter middle ring 1 is provided with two double-row angular contact spherical rolling element tracks 9, and the middle part of the outer circumference of the variable-diameter middle ring 1 is provided with a circle deep Groove spherical rolling element track 10, the deep groove spherical rolling element raceway 10 is arranged between the two turns of the double-row angular contact spherical rolling element track 9 set in the middle of the inner circumference of the relative variable diameter middle ring 1, forming a variable diameter middle ring Spherical rolling bodies 24 are respectivel...

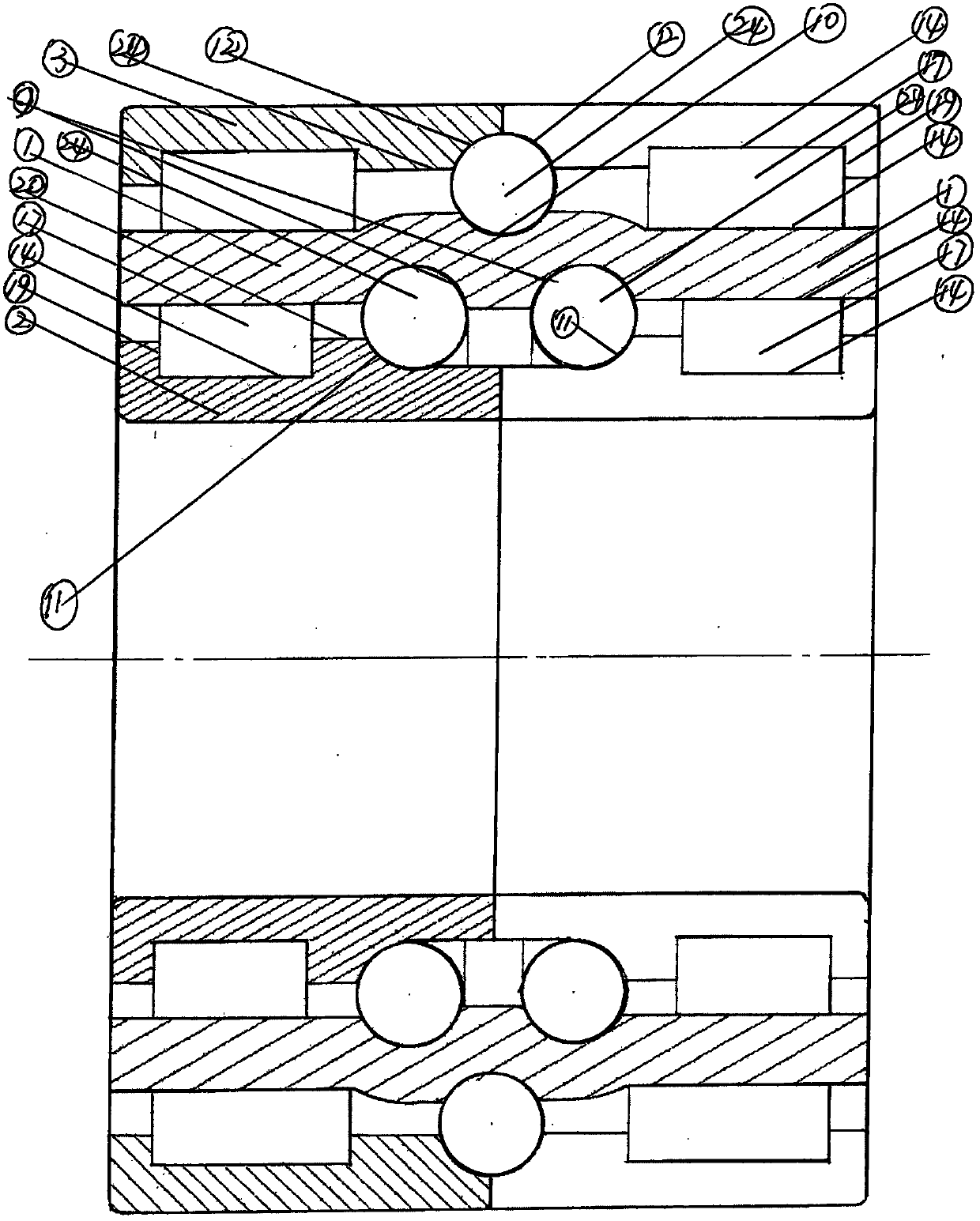

Embodiment 3

[0073] Such as image 3 The shown "new high-speed high-speed rail axle dynamic bearing" includes: a variable-diameter middle ring 1, two double-half inner rings 2, two double-half outer rings 3, and inner and outer two-layer rolling elements; Ring 1 is provided with two rings of double-row angular contact spherical rolling element track 9 at the middle distance of the axial distance of the inner circumference, and a ring of deep groove spherical rolling element track 10 is arranged at the middle of the axial distance of the outer circumference of ring 1 in variable diameter. Its deep-groove spherical rolling element raceway 10 is arranged between two turns of the double-row angular contact spherical rolling element track 9 arranged in the middle of the inner circumference of the variable-diameter middle ring 1, forming a variable-diameter middle ring, and the variable-diameter middle ring 1 The double-row angular contact spherical rolling element track 9 provided in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com