Compound microbial inoculum and preparation method and application thereof

A technology of composite bacterial agents and strains, applied in the direction of biochemical equipment and methods, separation methods, chemical instruments and methods, etc., can solve problems such as the impact of the surrounding environment, the health damage of chemical plant employees and surrounding residents, and ensure the richness , high-efficiency degradation ability, and the effect of improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

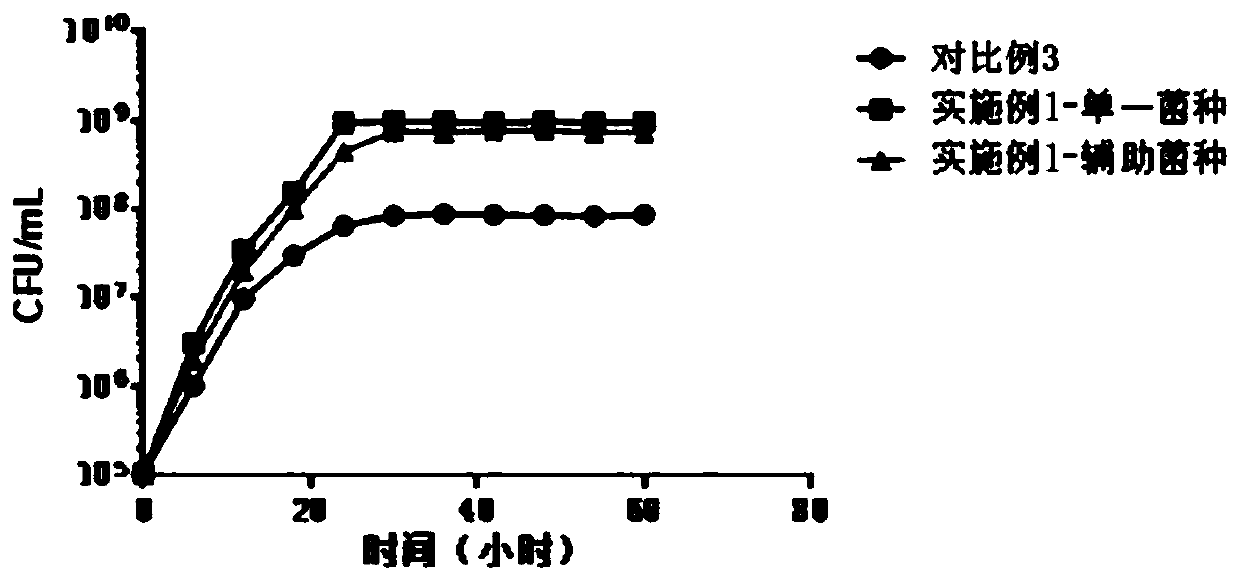

Embodiment 1

[0034] A preparation method of composite bacterial agent, comprising the following steps:

[0035] (A) Domestication of the original bacterial liquid: collect soil samples and sewage samples in the oil pollution source, mix them, and inoculate them in sterile water to cultivate the original bacterial liquid, pass petrochemical waste gas into the original bacterial liquid for domestication, and obtain domesticated strains;

[0036] (B) single fermentation of main strains: screen out Klebsiella from the domesticated strains, add culture medium solution in the main fermenter, and inoculate the screened Klebsiella, carry out fermentation and culture to obtain main seed liquid;

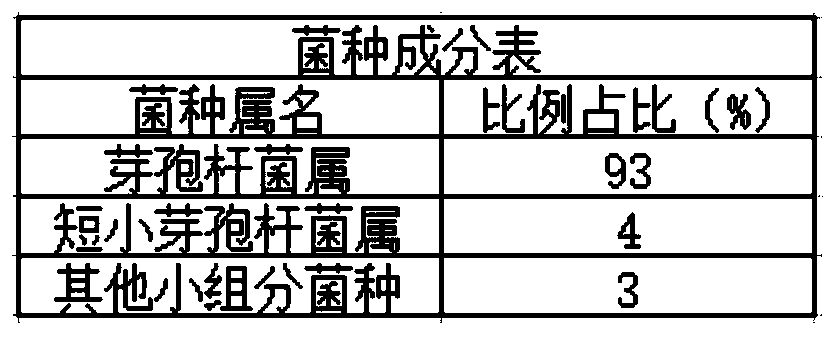

[0037] (C) mixed fermentation of auxiliary strains: add directional culture medium solution in the secondary fermenter, and inoculate domesticated strains, carry out fermentation and culture to obtain auxiliary strain liquid;

[0038] (D) stirring and mixing the main strain liquid and the auxiliary strain...

Embodiment 2

[0049] A preparation method of composite bacterial agent, comprising the following steps:

[0050] (A) Domestication of the original bacterial liquid: collect soil samples and sewage samples in the oil pollution source, mix them, and inoculate them in sterile water to cultivate the original bacterial liquid, pass petrochemical waste gas into the original bacterial liquid for domestication, and obtain domesticated strains;

[0051] (B) Fermentation of main strains: Klebsiella is screened out from the domesticated strains, culture medium solution is added to the main fermenter, and the screened Klebsiella is inoculated, and the main strains are obtained by fermentation. Seed liquid;

[0052] (C) mixed fermentation of auxiliary strains: add directional culture medium solution in the secondary fermenter, and inoculate domesticated strains, carry out fermentation and culture to obtain auxiliary strain liquid;

[0053] (D) stirring and mixing the main strain liquid and the auxiliar...

Embodiment 3

[0064] A preparation method of composite bacterial agent, comprising the following steps:

[0065] (A) Acclimatization of the original bacterial liquid: collect soil samples and sewage samples in the oil pollution source, mix them, inoculate them in sterile water to cultivate the original bacterial liquid, pass petrochemical waste gas into the original bacterial liquid for domestication, and obtain domesticated strains;

[0066] (B) Fermentation of main strains: Klebsiella is screened out from the domesticated strains, culture medium solution is added to the main fermenter, and the screened Klebsiella is inoculated, and the main strains are obtained by fermentation. Seed liquid;

[0067] (C) mixed fermentation of auxiliary strains: add directional culture medium solution in the secondary fermenter, and inoculate domesticated strains, carry out fermentation and culture to obtain auxiliary strain liquid;

[0068] (D) stirring and mixing the main strain liquid and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com