Packaging adhesive film for photovoltaic module

A technology for encapsulating adhesive films and photovoltaic modules, applied in adhesives, film/sheet adhesives, adhesive additives, etc., can solve problems such as high cost, easy precipitation of additives, delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

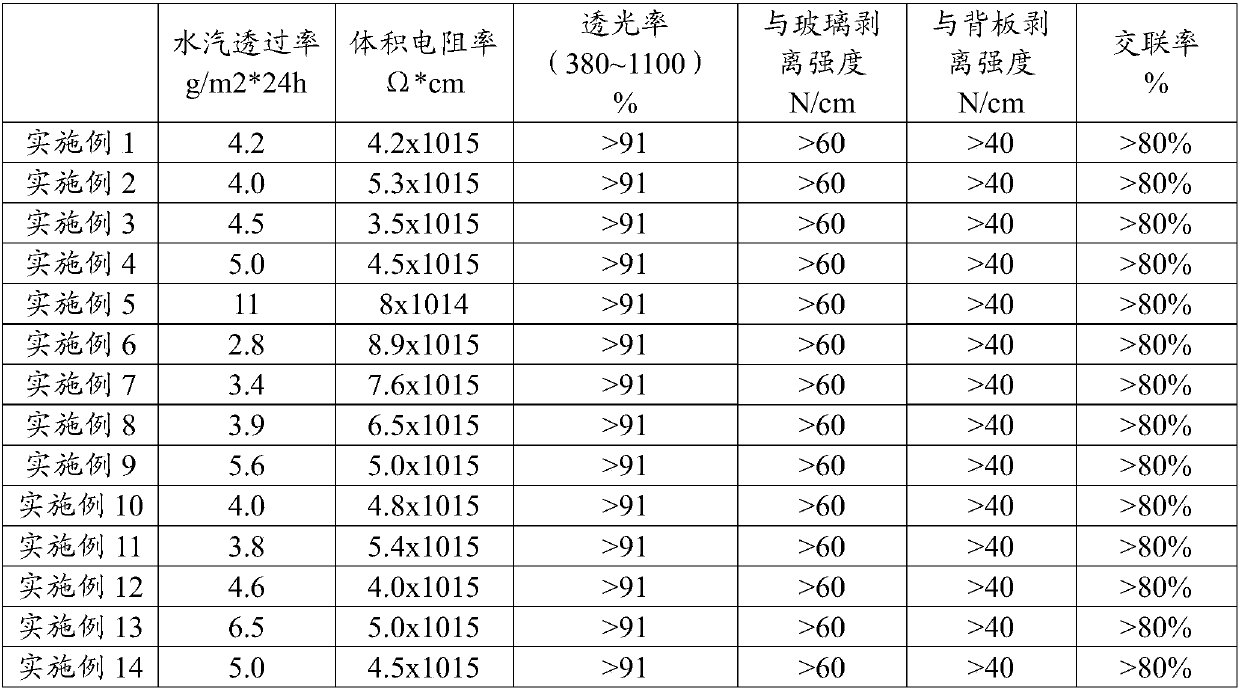

Examples

Embodiment 1

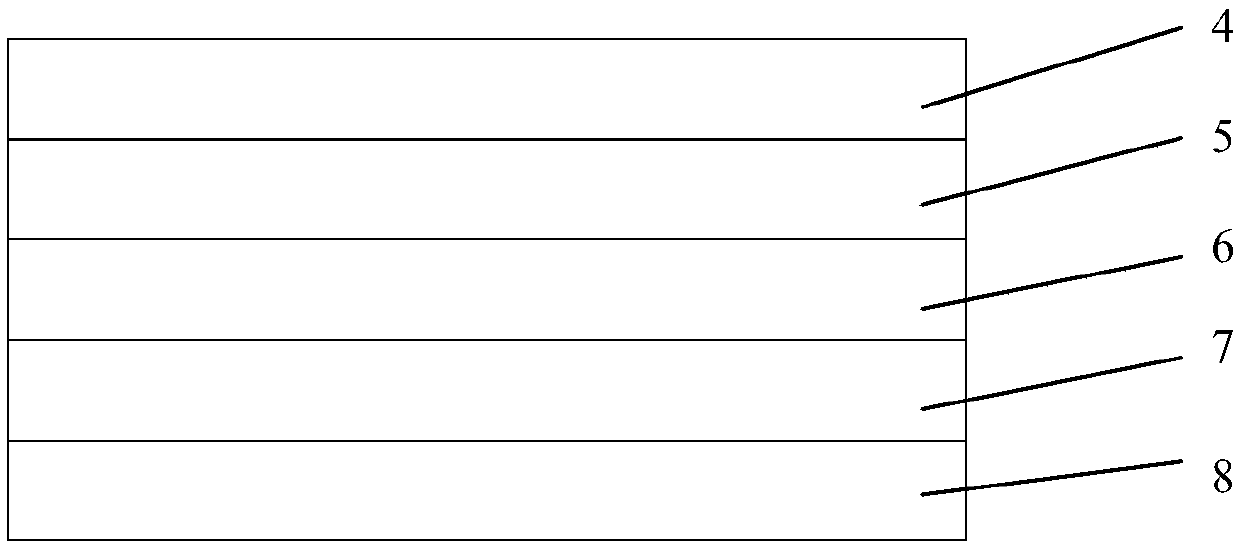

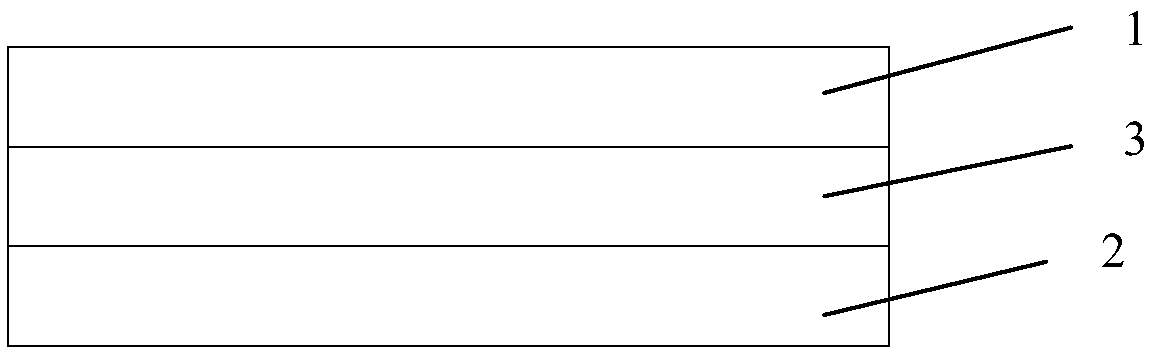

[0019] This embodiment provides as figure 2 The structure of the film, the film structure is three layers, including the outer layer 1, the inner layer 2, the middle layer 3, the inner and outer layers are EVA resin, the middle layer is POE resin. The overall thickness of the adhesive film is 500 microns, the thickness of the middle layer is 250 microns, and the thickness of the inner and outer layers of EVA is 125 microns. The melt flow rate of the POE resin is 15 g / min, the melt flow rate of the EVA resin is 5 g / min, and the VA content is 28%. 0.9 parts by mass of ethoxylated pentaerythritol triacrylate was added to each layer.

Embodiment 2

[0021] The adhesive film provided by this embodiment is basically the same as the adhesive film in Example 1, except that the melt flow rate of the inner and outer layers of EVA resin is 2g / min, the VA content is 26%, and the melt flow rate of the middle layer POE resin The rate was 5 g / min. 2.1 parts by mass of propoxylated neopentyl glycol diacrylate was added to each layer.

Embodiment 3

[0023] The adhesive film provided by this embodiment is basically the same as the adhesive film in Example 1, except that the melt flow rate of the inner and outer layers of EVA resin is 16g / min, the VA content is 32%, and the melt flow rate of the middle layer POE resin The rate was 25 g / min. 1.1 parts by mass of ethoxylated trimethylolpropane triacrylate was added to each layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com