Preparation method of 3,3,5-trimethylcyclohexanone

A technology of trimethylcyclohexanone and hydrogenation catalyst, which is applied in the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the need to add heavy metal Cr and low selectivity of trimethylcyclohexanone. , unfavorable environmental protection and other problems, to achieve the effect of continuous preparation of saving subsequent separation energy consumption, high selectivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

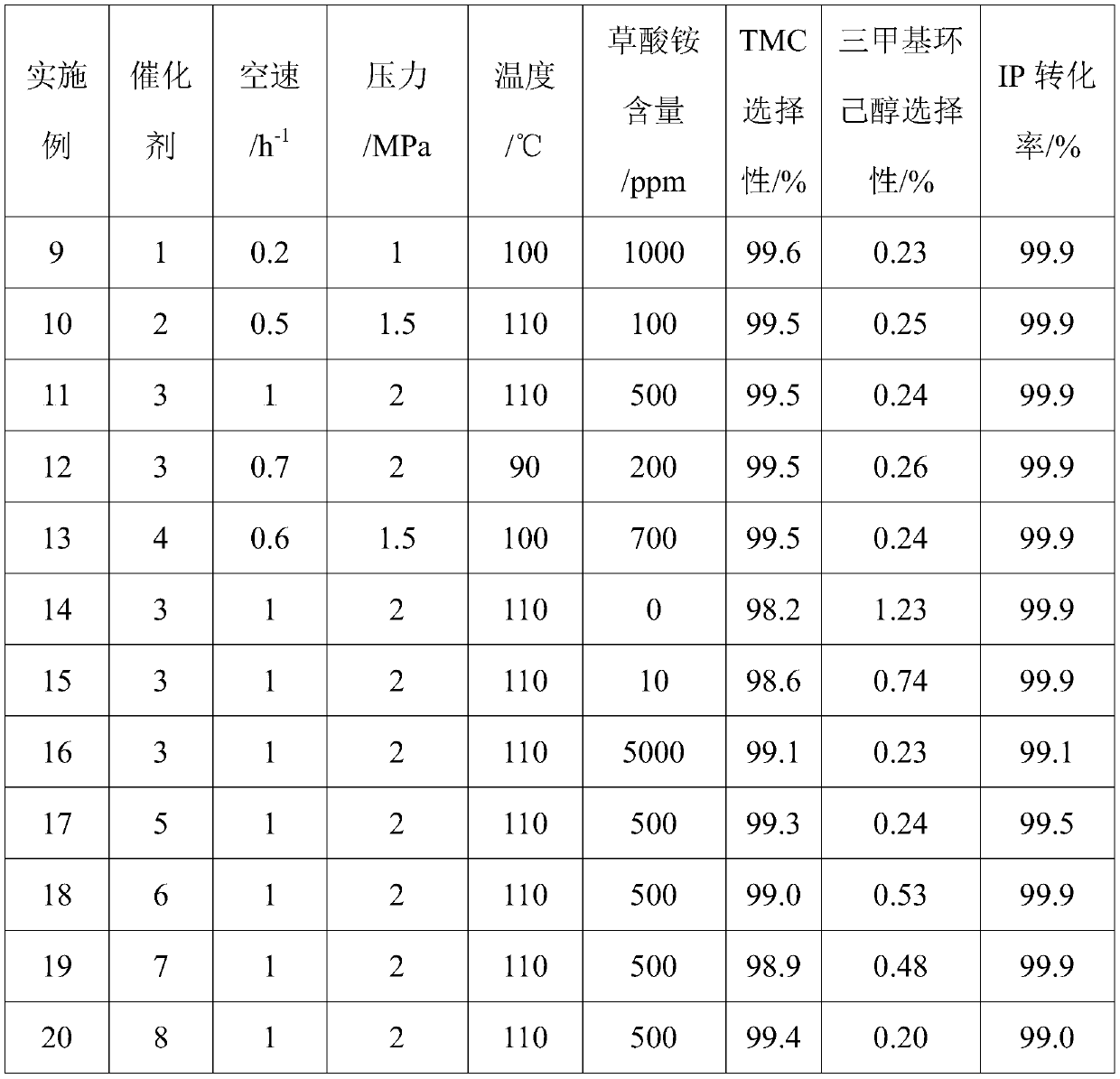

Examples

Embodiment 1

[0029] Using equal volume impregnation method, 38.9gNi(NO 3 ) 2 ·6H 2 O and 0.14g of sodium carbonate were added to water under stirring. After all the salt was dissolved, water was added until the volume of the solution was 100ml. Stirring was added in batches of 100g of alumina as a carrier, and it was soaked at room temperature for 24 hours to form a 2-3mm clover shape. Dry at 120°C for 2h; then calcinate at 600°C for 6h to obtain Catalyst 1. Calculated as NiO, the loading amount of Ni is 10wt% of the carrier, and the content of the modifying agent sodium carbonate calculated as Na element is 2% of the molar amount of Ni.

Embodiment 2

[0031] Using equal volume impregnation method, 77.8gNi(NO 3 ) 2 ·6H 2O and 1.14g of sodium carbonate were added to water under stirring. After all the salt was dissolved, water was added until the volume of the solution was 100ml. Stirring was added in batches of 100g of alumina as a carrier, and it was soaked at room temperature for 24h, and then formed into a 2-3mm clover shape. Dry at 120°C for 2h; then calcinate at 600°C for 6h to obtain catalyst 2. Calculated as NiO, the loading amount of Ni is 20wt% of the carrier, and the amount of modifier sodium carbonate calculated as Na element is 8% of the molar amount of Ni.

Embodiment 3

[0033] Using equal volume impregnation method, 58.4gNi(NO 3 ) 2 ·6H 2 O and 0.53g of sodium carbonate were added to water under stirring. After all the salt was dissolved, water was added until the volume of the solution was 100ml. Stirring was added in batches of 100g of alumina as a carrier, and it was soaked at room temperature for 24 hours, and then formed into a 2-3mm clover shape. Dry at 120°C for 2h; then calcinate at 600°C for 6h to obtain catalyst 3. Calculated as NiO, the loading amount of Ni is 15wt% of the carrier, and the amount of modifier sodium carbonate calculated as Na element is 5% of the molar amount of Ni.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com