Device and process for recycling waste sulfuric acid

A technology for recovery and treatment of waste sulfuric acid, which is applied in the direction of magnesium sulfate, bisulphate preparation, sulfate/bisulfate preparation, etc., can solve problems such as improper process, different sources of waste acid, complex components, etc., and achieve low-cost recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

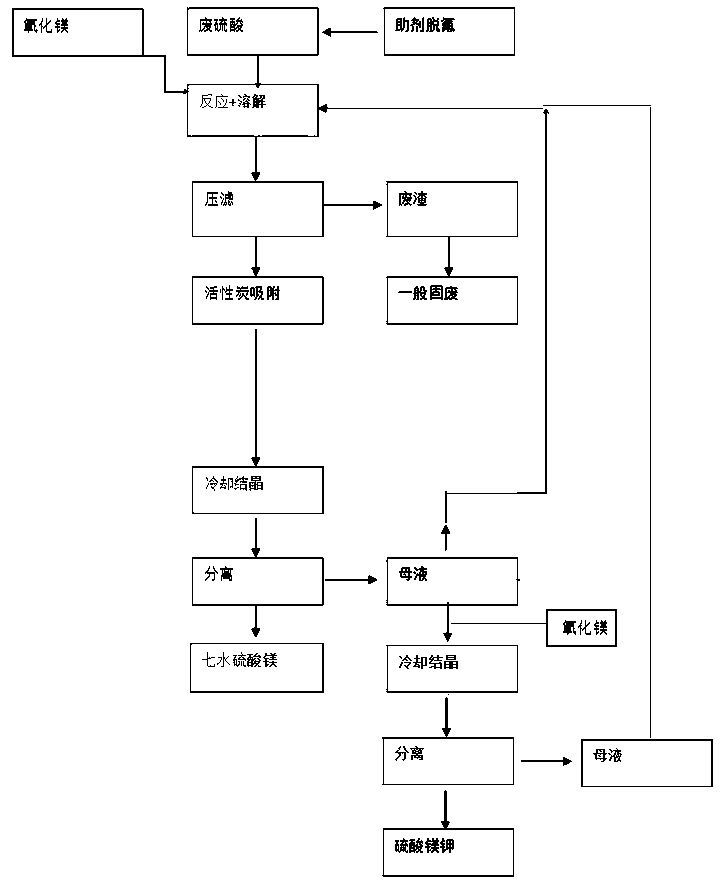

[0031] A method for recovering and treating waste sulfuric acid. The waste sulfuric acid contains 75-80% sulfuric acid, 5-10% potassium bisulfate and 0.2-0.5% boron trifluoride. The treatment method comprises the following steps:

[0032] S1: Transfer waste sulfuric acid to the defluorination reactor, add defluorination additives for defluorination pretreatment; Harmless fluoride. The waste acid is accurately metered into the defluorination reactor, and the defluorination aid is added through the control system according to the analysis data, and the defluorination waste acid enters the reactor.

[0033] S2: Transfer the pretreated waste sulfuric acid to the reactor, add magnesium oxide into the reactor, react until the pH value reaches neutral, add iron remover and flocculant while stirring, continue the reaction, add iron remover and Flocculation makes iron and other impurities form precipitates, removes iron and most of the impurities, and the tail gas discharged from the ...

Embodiment 2

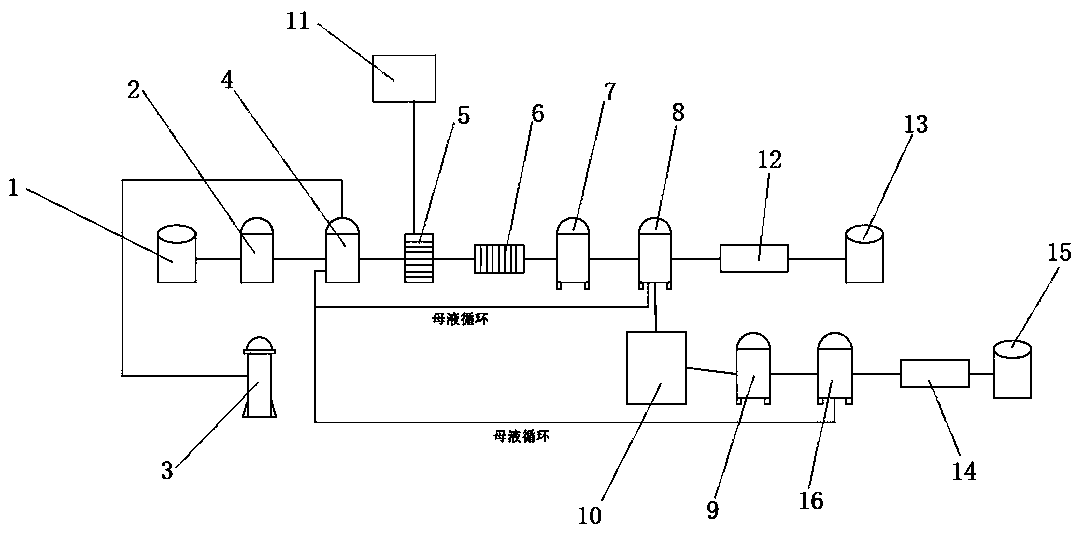

[0040] A recovery and treatment device for waste sulfuric acid, comprising a waste sulfuric acid storage tank 1, a defluorination reactor 2, an absorption tower 3, a reaction kettle 4, a filter press 5, activated carbon filter equipment 6, a first crystallization kettle 7, a first centrifugal separation machine 8, the second crystallization kettle 9, mother liquor transfer tank 10, the second centrifuge 16, waste residue storage tank 11, the first dryer 12, magnesium sulfate storage tank 13, the second dryer 14 and magnesium sulfate potassium storage tank 15. The reaction kettle 4 is a reaction kettle 4 with a stirring function, and the reaction kettle 4 is also provided with an iron removal agent feeding port and a flocculant feeding port. Both the first centrifugal separator 8 and the second centrifugal separator 16 are automatic continuous separators.

[0041] The waste sulfuric acid storage tank 1 is used to store the waste sulfuric acid to be recovered, the defluorinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com