Method for solving shrinkage porosity of investment casting aluminum alloy casting

A technology of aluminum alloy castings and investment casting, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as shrinkage porosity of castings, and achieve the effect of eliminating shrinkage porosity defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The present invention is further described in detail below by specific embodiment:

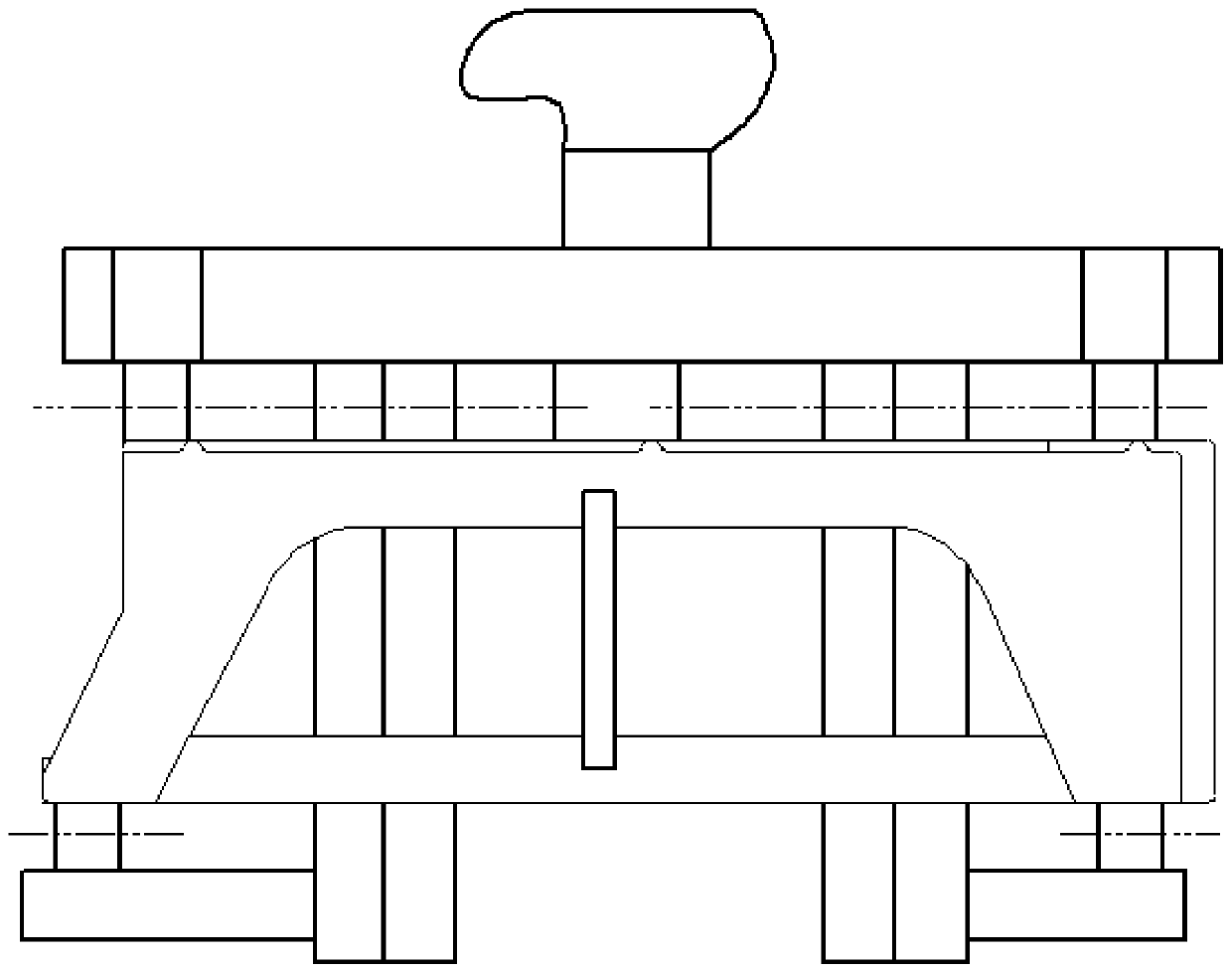

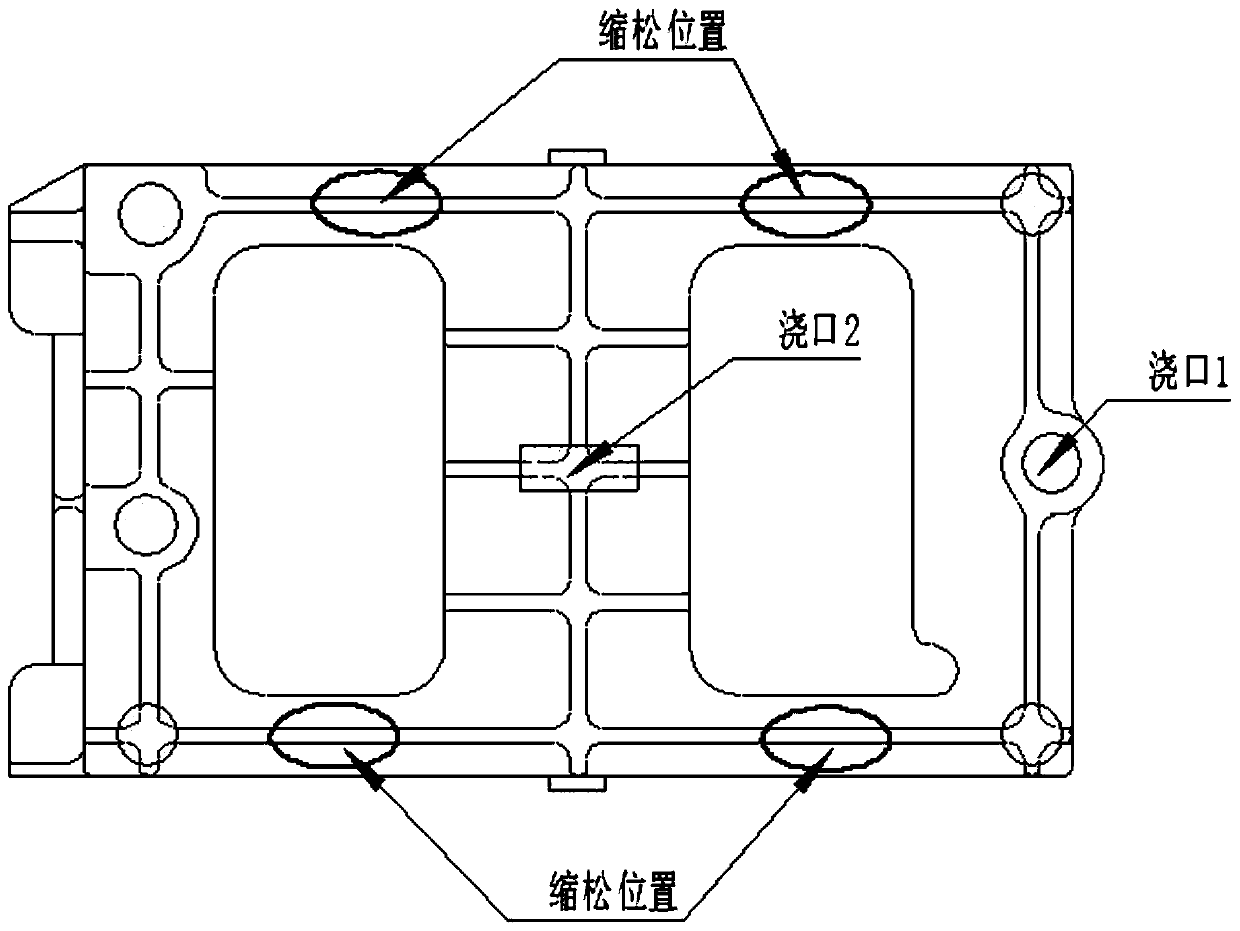

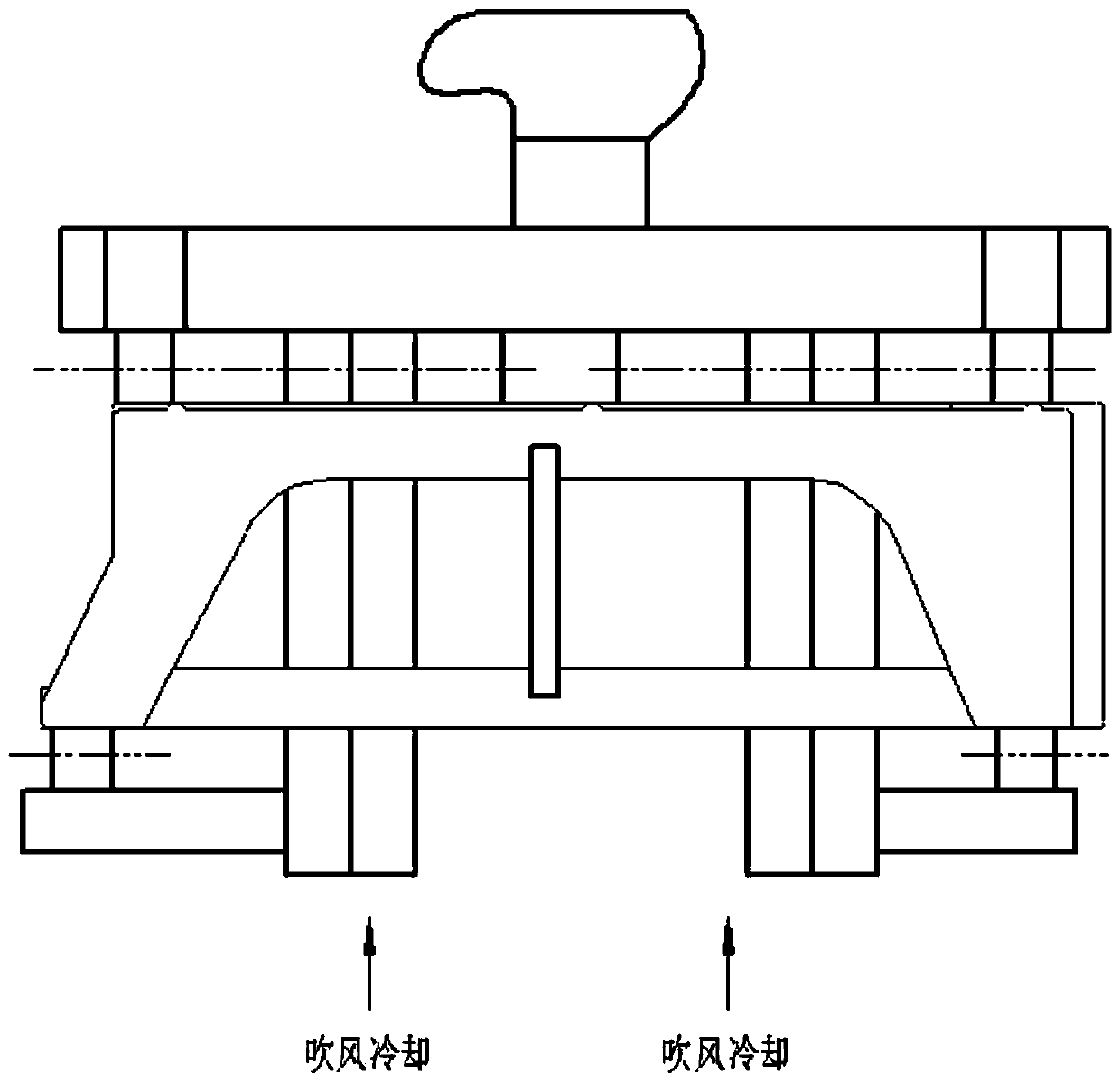

[0045] The ZL116 material bearing casting used by a certain type of aircraft, the outline size is 333 × 192 × 98 (mm), the type II casting. This casting adopts investment casting method, vacuum smelting and vacuum casting, the combined process see figure 1 , the production pass rate is 45%, the defects are mainly X-ray inspection shrinkage, see the shrinkage position figure 2 . In order to solve the problem of shrinkage porosity of castings, high-pressure drying air is used to force cooling the shrinkage porosity of castings. For this purpose, a special blowing device for the support is made, which can blow air at the shrinkage porosity at the same time.

[0046] A 25Kg vacuum induction furnace is used for smelting and casting, and the cooling rack and blowing device are placed in appropriate positions in advance, and then smelting and casting are carried out. First, put the preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com