Powder compaction testing machine for portable fire extinguisher

A fire extinguisher and portable technology, which is applied in the field of portable fire extinguisher powder compaction test equipment, can solve the problems of no test equipment, etc., and achieve the effect of simple structure, low cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

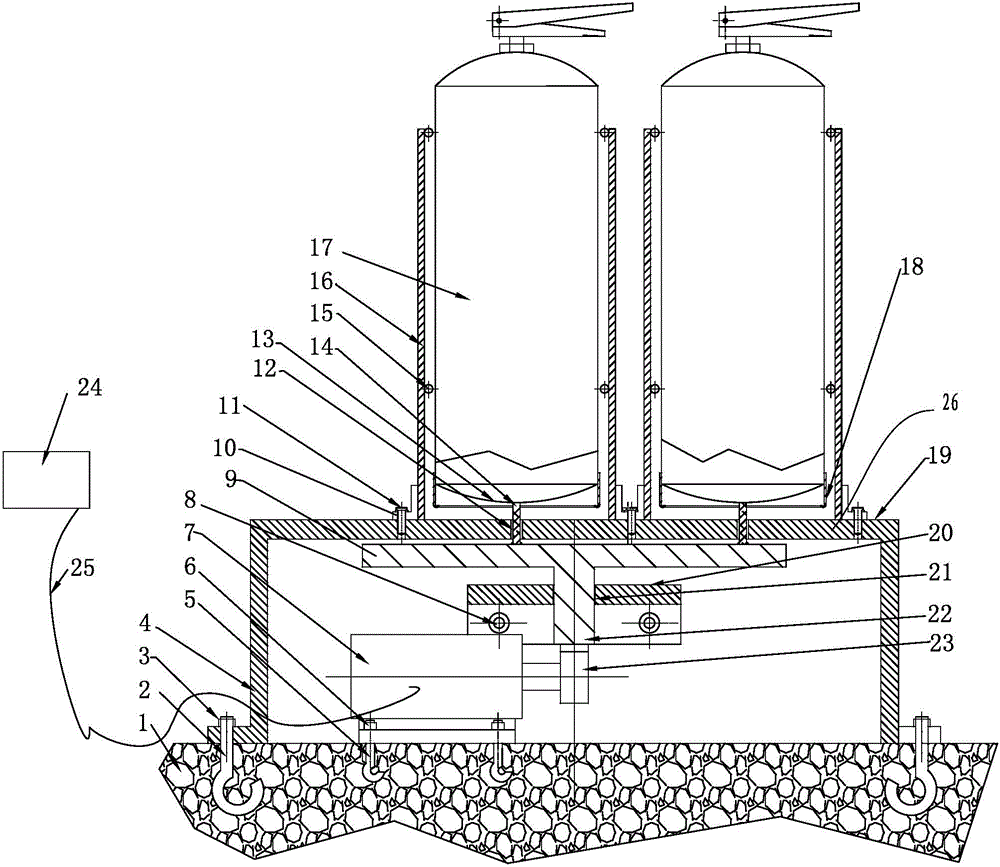

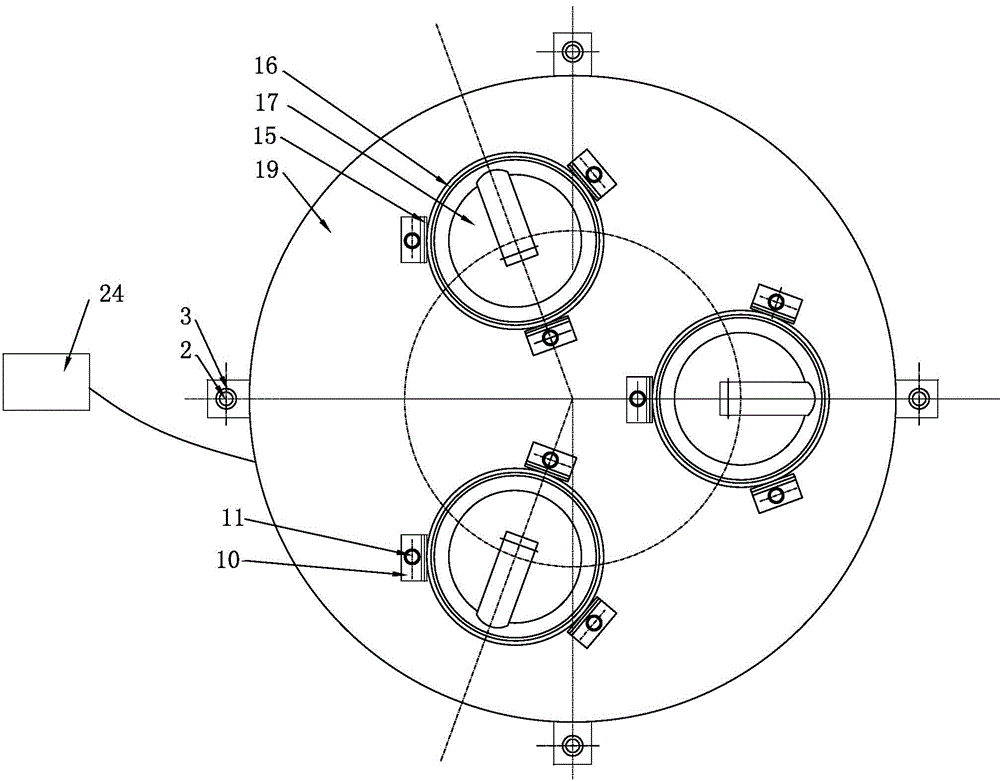

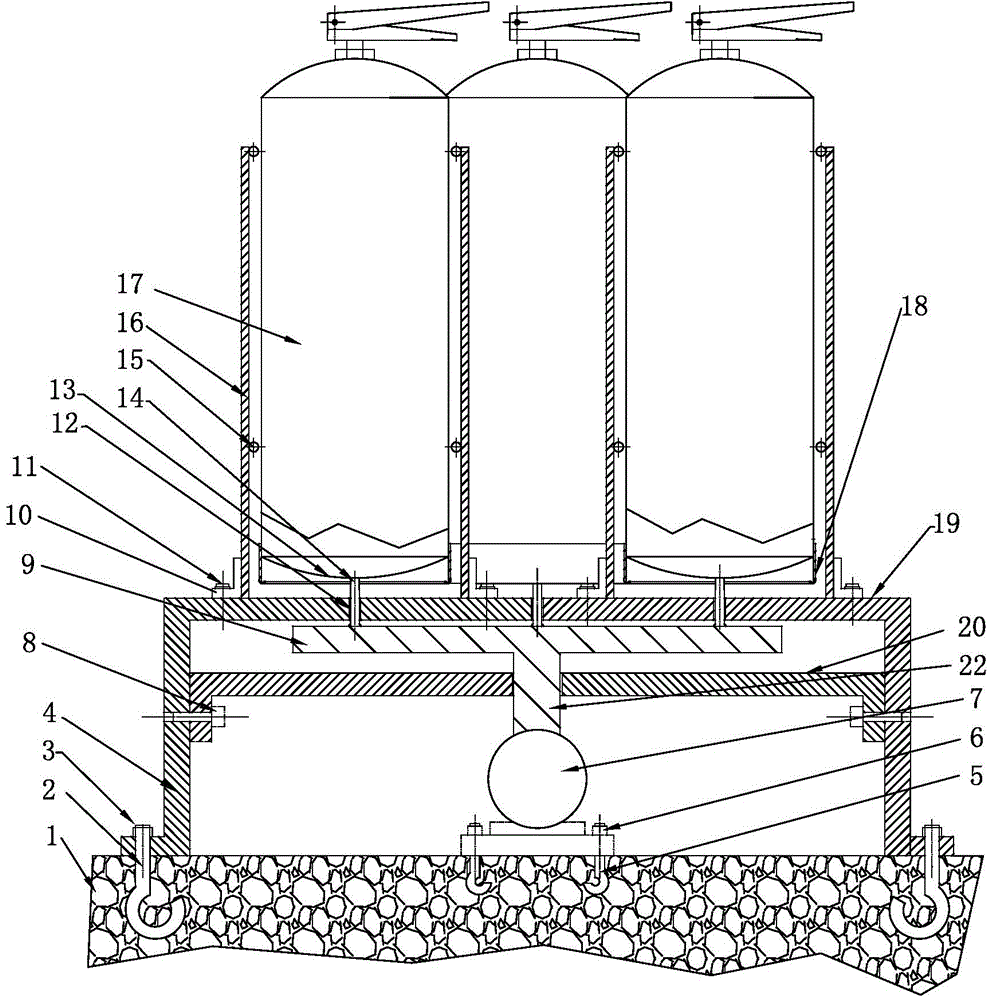

[0026] Such as figure 1 , figure 2 , image 3 As shown, a portable fire extinguisher powder compaction testing machine mainly includes a stand 6, a rigid test stand 4, a push rod 14, a moving plate 9 up and down, a fixed supporting plate 20, a cam 23, a servo motor 7, and a programming controller PLC And motor governor and counter 24.

[0027] Stand 6 and portable fire extinguisher 17 are set in one-to-one correspondence, for placing portable fire extinguisher 17 and for portable fire extinguisher 17 to move up and down in stand 6, described stand 16 is provided with portable fire extinguisher 17 cooperation Guide hoop 15. In this embodiment, three stands 6 are provided. Moreover, this embodiment further sets the stand 16 into a cylindrical shape, and the stand 16 is coaxial with the guide hoop 15, so that the portable fire extinguisher 17 can be conveniently placed and reliably provided for the portable fire extinguisher 17 to go up and down. move.

[0028] The table t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com