Fatigue test device for car hood lock buckle

A fatigue test and engine cover technology, applied in the field of latch assembly, can solve the problems of high processing and installation precision requirements for four guide rods, easily damaged parts of the test device, and insufficient test efficiency, achieving a high degree of automation and convenient operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

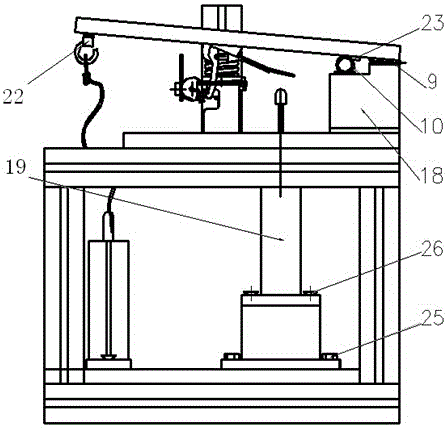

[0014] like Figure 1 to Figure 4 As shown, a car engine hood lock fatigue test device includes a lock 1, a tooling bracket 2, a lower pressure plate 3, a bolt 4, a bolt 5, a latch 6, an oblique pressure plate 7, a bolt 8, a hinge support 9, Torsion compression spring 10, skeleton upper beam 11, skeleton lower beam 12, tooling base plate 13, tension cylinder 14, left frame column 15, unlocking cylinder 16, steel wire bundle 17, steel wire bundle 20, height adjustment block 21, tooling beam 18, Thrust unlocking cylinder 19, bolt hook 22, bearing pin 23, bolt 24, bolt 25, screw 26, bolt 27.

[0015] Insert the lock 1 of the hood lock of the car after assembly into the shaft pin hole of the tooling bracket 2 and fix it. The tooling bracket 2 and the lower pressure plate 3 are fixedly connected by bolts 4, and the lower pressure plate 3 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com