Synchronous welding device of double-headed riveting pipe of automobile seat

A car seat and riveting tube technology, which is applied in the field of car seat frame assembly device, can solve problems such as poor symmetry and concentricity, uneven flanging, high scrap rate, etc., and achieves convenient operation, reliable movement, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

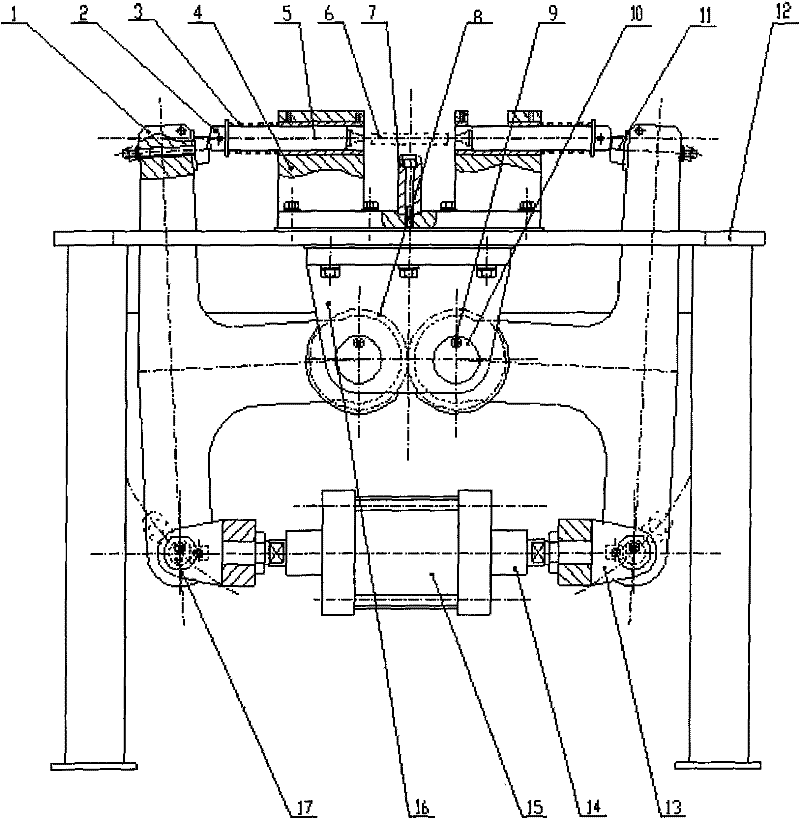

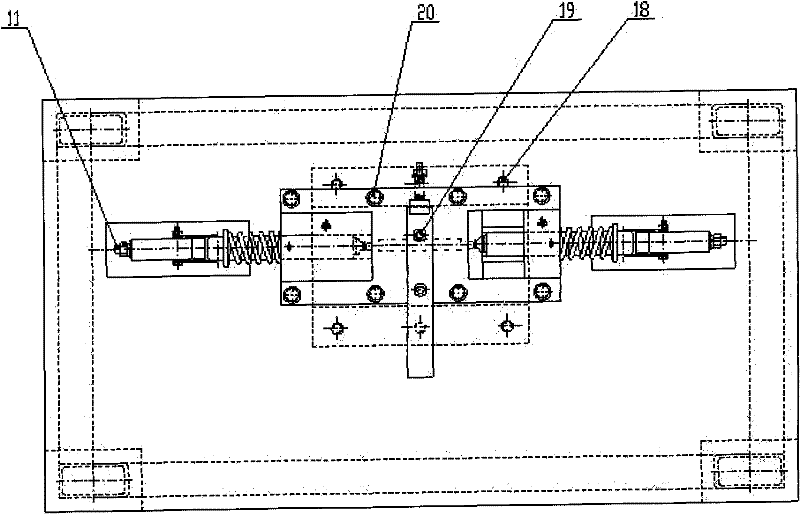

[0011] Such as figure 1 , as shown in 2, the car seat double-head riveting tube synchronous pressing device of the present invention includes a pressure lever 1, a ball screw 2, a compression spring 3, an upper fixed support 4, a thimble shaft 5, and a rolling pin 6 , tooling boss 7, spur gear 8, shaft pin 10, workbench 12, cylinder connector 13, cylinder 15, lower fixed support 16, pin shaft 17, lower fixed support bolt 18, tooling boss fixing bolt 19, Fix the support bolt 20 on the top.

[0012] Workbench 12 is equipped with tooling boss 7, and tooling boss 7 both sides are respectively fixedly connected with upper fixed bearing 4, and upper fixed bearing 4 top is inserted with ball screw rod 2, and the rear end surface of ball screw rod 2 and A compression spring 3 is arranged between the sides of the upper fixed support 4, and the ball head of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com