Fixed-point quantitative refueling device for car seat chute

A technology for car seats and refueling devices, applied in the direction of quantitative devices, lubricating parts, engine lubrication, etc., can solve the problems of car decoration pollution, grease overflow, insufficient lubrication, etc., achieve high degree of automation, ensure reliability, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

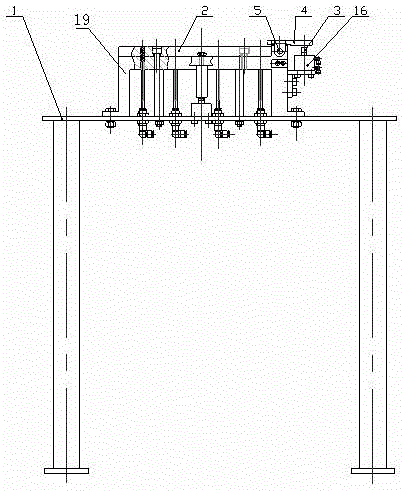

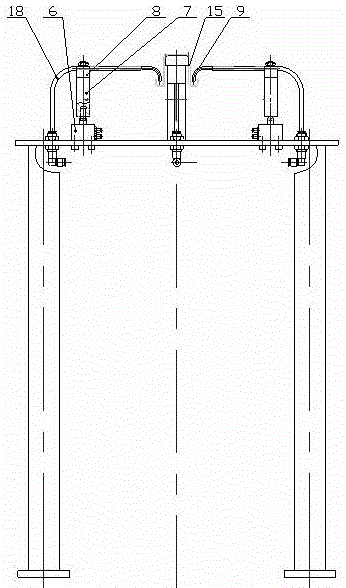

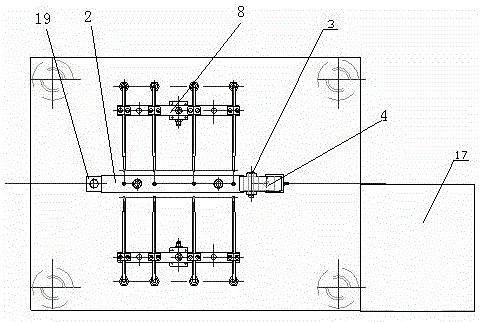

[0015] Such as Figure 1 to Figure 4 As shown, a fixed-point and quantitative refueling device for a car seat chute includes a workbench 1, a guide plate 2, a compression cylinder ejector 3, a compression plate 4, a pin shaft 5, a cylinder 6, a cylinder ejector 7, and an oil circuit Distribution strip 8, fixed-point nozzle 9, two-position five-way reversing valve A10, two-position five-way reversing valve B11, seat frame chute 15, compression cylinder 16, oil station 17, oil pipeline 18, tooling bracket 19.

[0016] Tooling bracket 19 is installed in the middle of workbench 1, and guide plate 2 is housed above tooling bracket 19, and one end of tooling bracket 19 is movably connected to compression plate 4 by bearing pin 5, and compression plate 4 is provided with the compression plate that is fixed on tooling bracket 19 sides below. Compression cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com