Automatic assembling equipment for network cable connector

An automatic assembly, network cable technology, applied in the assembly/disassembly, connection, connection and connection of contacts, etc., can solve the problems of low degree of automation, low efficiency, easy winding of wires, etc., to achieve a high degree of automation, guaranteeing Electrical, not easy to entangle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

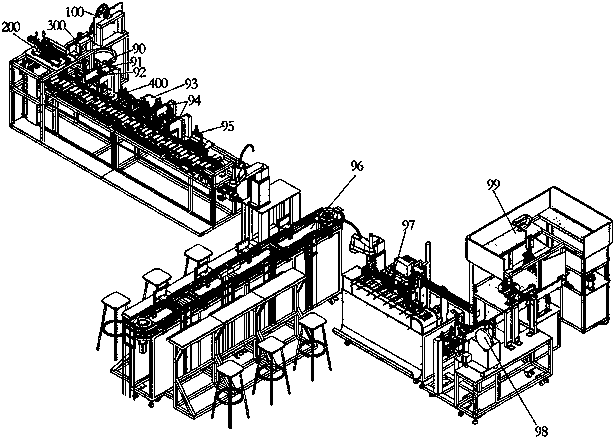

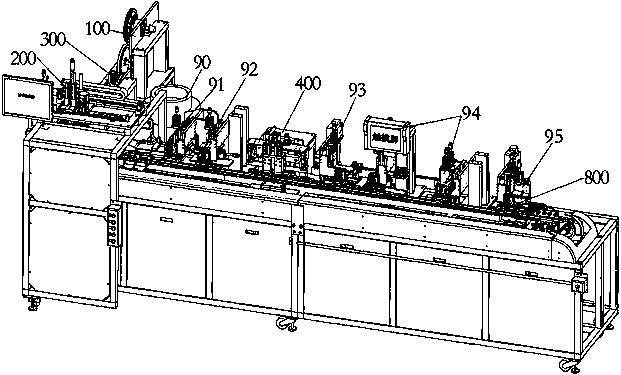

[0037] The present invention provides an automatic assembly equipment for network cable joints. Referring to the accompanying drawings, the following equipment or procedures are used for processing in sequence:

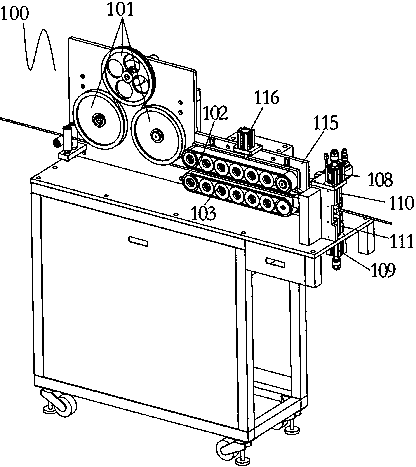

[0038] (1) On-line device, which sequentially includes the drawing and cutting assembly 100, the clamping assembly 200, and the wire-taking assembly 300 according to the processing sequence of the network wire, which is used to cut the network wire according to a preset length and move it to the clamp 803 of the conveying device 800 superior.

[0039] (1-1) Extract the cutting assembly 100, which includes the meter counting wheel set 101, the upper synchronizing wheel set 102 and the lower synchronizing wheel set 103 correspondingly arranged below it, and the cutting assembly for network line cutting in sequence according to the processing seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com