Floor-wiping and shoe-wiping dual-purpose machine

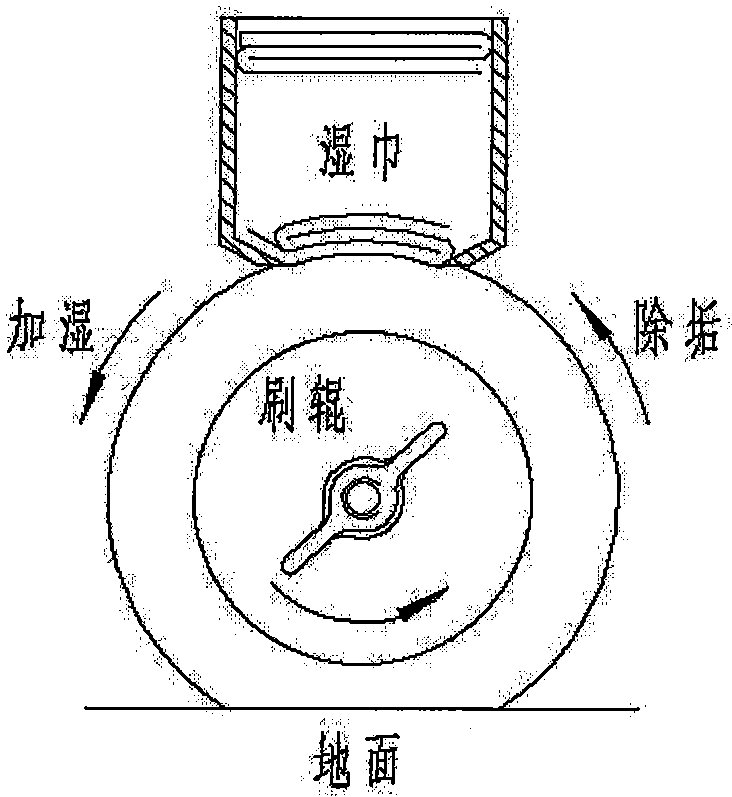

A dual-purpose, chassis technology, applied in applications, carpet cleaning, floor cleaning, etc., can solve the problems of limited intelligence of automatic sweepers and mopping machines, difficult to clean fine dust, and loud vacuum cleaners, etc. , Reduce residual water and ensure the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

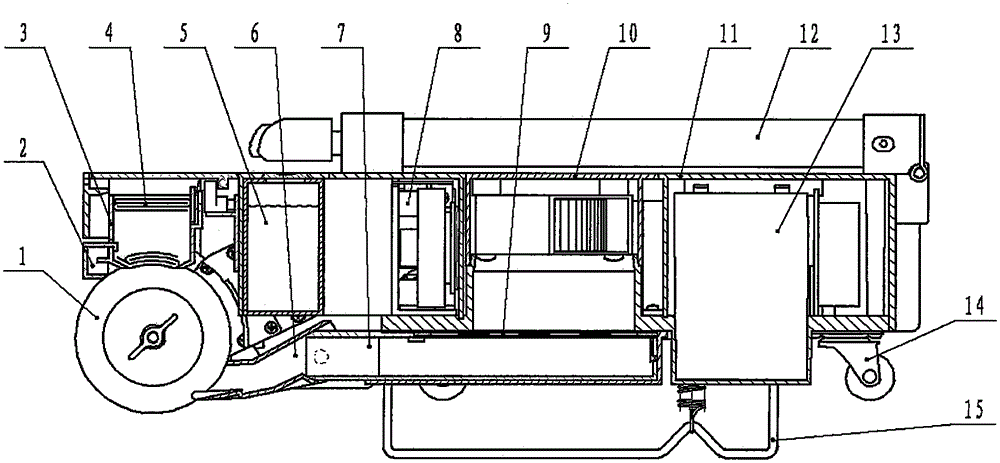

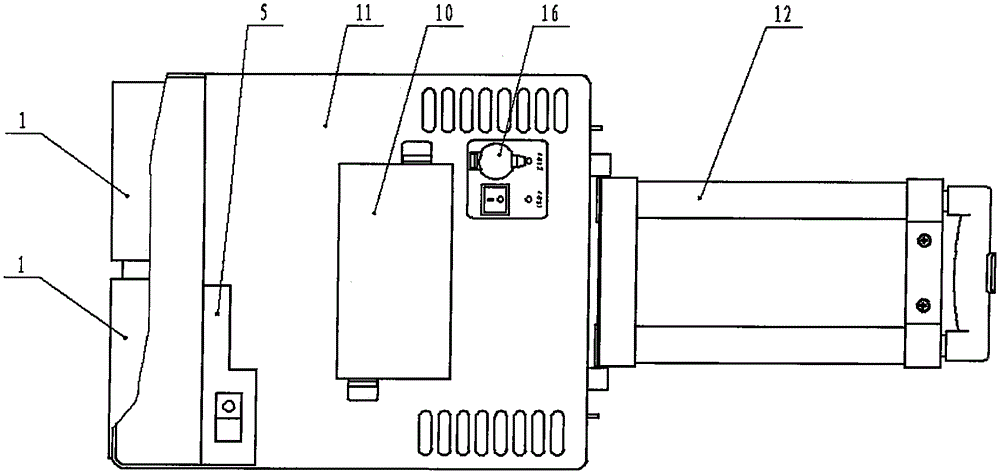

[0029] Figure 2 to Figure 13 It is a typical implementation of this technical solution, and its basic parameters are: the size of the chassis is 410mm (length) × 340mm (width) × 115mm (height), the weight is about 12kg, and the working efficiency is 300m 2 / h.

[0030] figure 2 Among them, the brush roller (1) installed on the movement mechanism (8) is located at the front and lower part of the cabinet (11), and the dust suction nozzle (6) is installed close to the ground behind the brush roller, the mouth of the dust suction nozzle is close to the brush roller, and the tail Connect the dust collection box (7), the dust collection box is installed on the bottom of the chassis (11), the bottom of the chassis is provided with an air induction channel at the dust filter port of the dust collection box, the fan box (9) is connected above the air induction channel, and the fan box is connected with The card is fixed on the top of the chassis from the outside. Storage battery (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com