Capacitor structure and manufacturing method thereof

A capacitor structure and manufacturing method technology, applied in capacitors, electric solid devices, circuits, etc., can solve the problem of low stability of the capacitor support layer, achieve the effects of reducing the risk of rupture, increasing support stability, and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

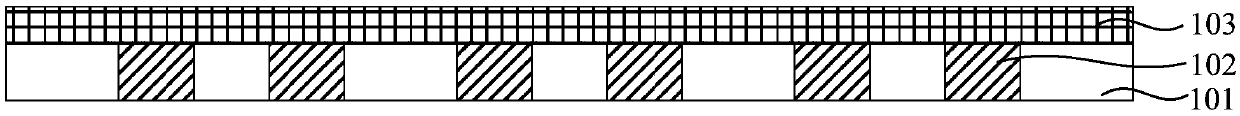

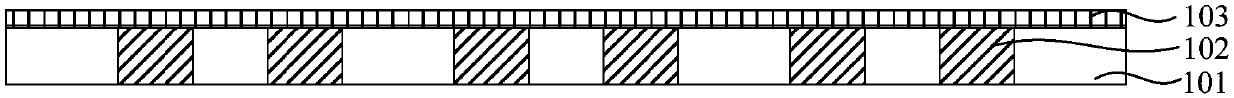

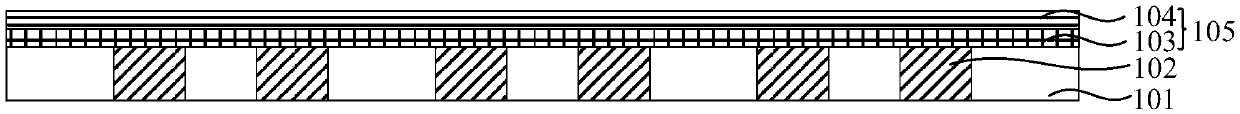

[0066] Such as Figure 1 to Figure 17 As shown, this embodiment provides a manufacturing method of a capacitor structure, the manufacturing method comprising:

[0067] S1: Provide a bottom substrate 101, and sequentially form an etch stop layer 105, a lower sacrificial layer 108, a middle support layer 109, a top sacrificial layer 110, a first support layer 111 and a stress relief layer 112; wherein the base substrate 101 has a contact hole 102 passing through its upper surface and lower surface;

[0068] S2: Form a first pattern mask 113 on the upper surface of the stress relief layer 112, and etch the stress relief layer 112 based on the first pattern mask 113 to form a pattern exposing the first support. stress relief portion 114 of layer 111;

[0069] S3: Form a second support layer 115 on the upper surface of the first support layer 111 and the surface of the stress relief portion 114, wherein the first support layer 111 and the second support layer 115 relieve the stres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com