Grease lubrication rolling bearing service life acceleration experiment device based on switched reluctance motor

A technology of switched reluctance motor and rolling bearing, applied in the field of machinery, can solve the problems of complex structure of non-switched reluctance motor, not meeting economic requirements and high cost, and achieve the effects of saving test cost, shortening test period and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

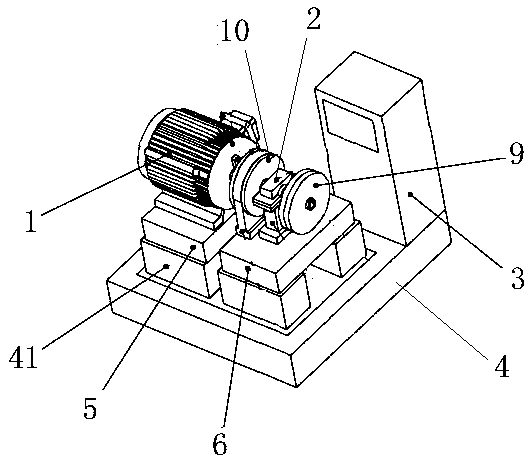

[0022] This embodiment proposes an experimental device for accelerating the life of a grease-lubricated rolling bearing based on a switched reluctance motor. The experimental device can control the experimental temperature to obtain more accurate measurement data.

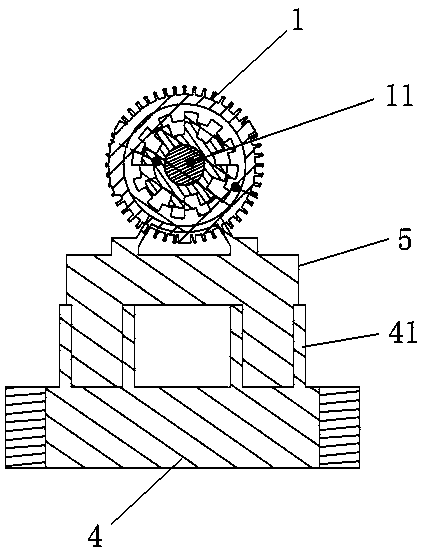

[0023] Such as Figure 1~3 As shown, the grease lubricated rolling bearing life acceleration experiment device based on switched reluctance motor in this embodiment includes a shock absorber frame, switched reluctance motor 1, support module 2, and a controller 3 for controlling the operation of switched reluctance motor 1 ,in:

[0024] The shock-absorbing frame is composed of the shock-proof asphalt board 4 and the driving frame 5 and the support frame 6 fixed on the shock-proof asphalt board 4 at intervals. Concrete support columns at both ends of the board, the top surface of the shockproof asphalt slab 4 is provided with a protruding limit sleeve 41, the support column is inserted downward into the limit sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com