Prefabricated dismantling-free floor laminated plate and process for processing prefabricated dismantling-free floor laminated plate

A processing technology and technology of laminated slabs, applied to floors, manufacturing tools, building components, etc., can solve the problems that two floor laminated slabs cannot be used in combination, the fixing effect is not good, and the production cost is high, so as to reduce the unit water consumption , Improve workability, save installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

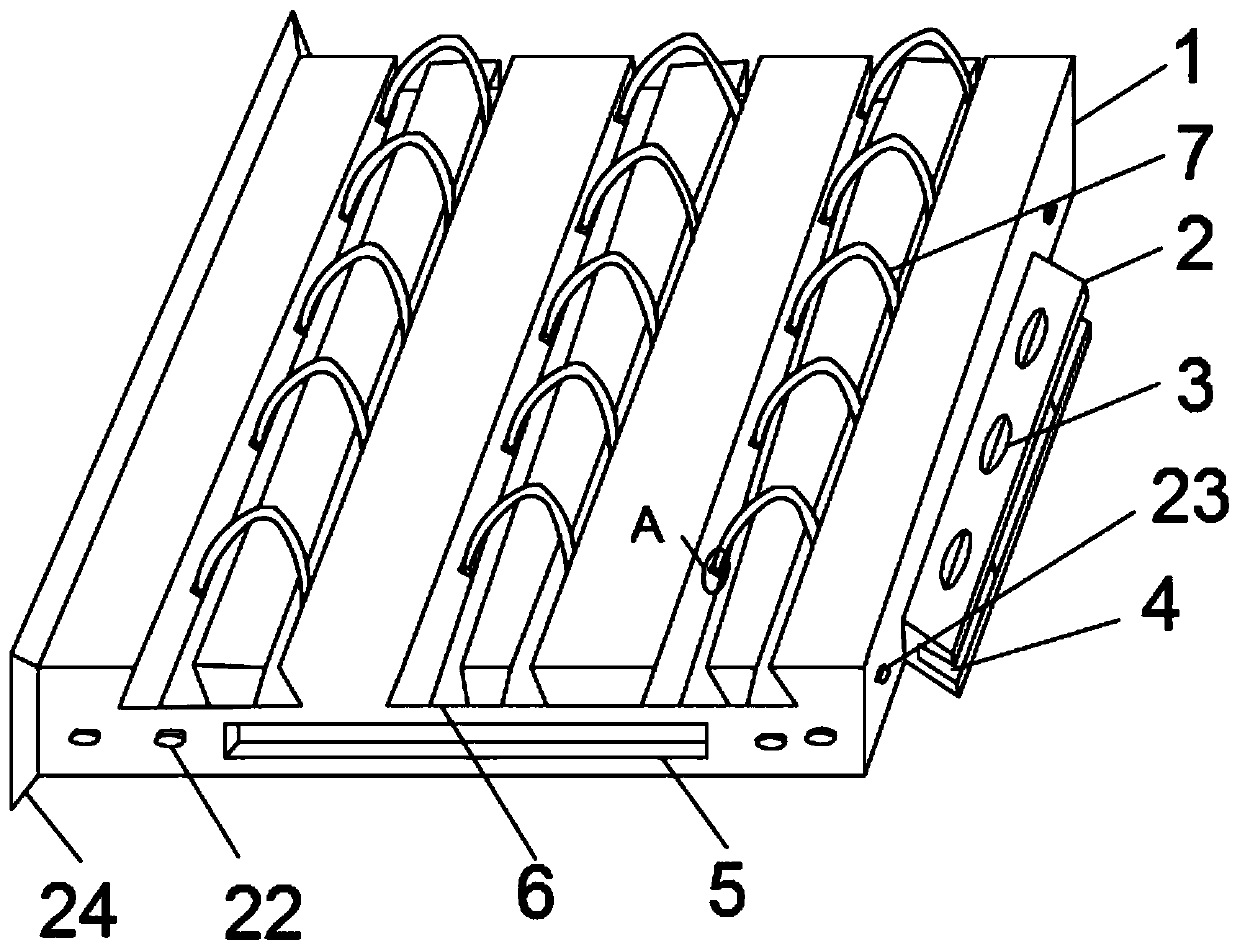

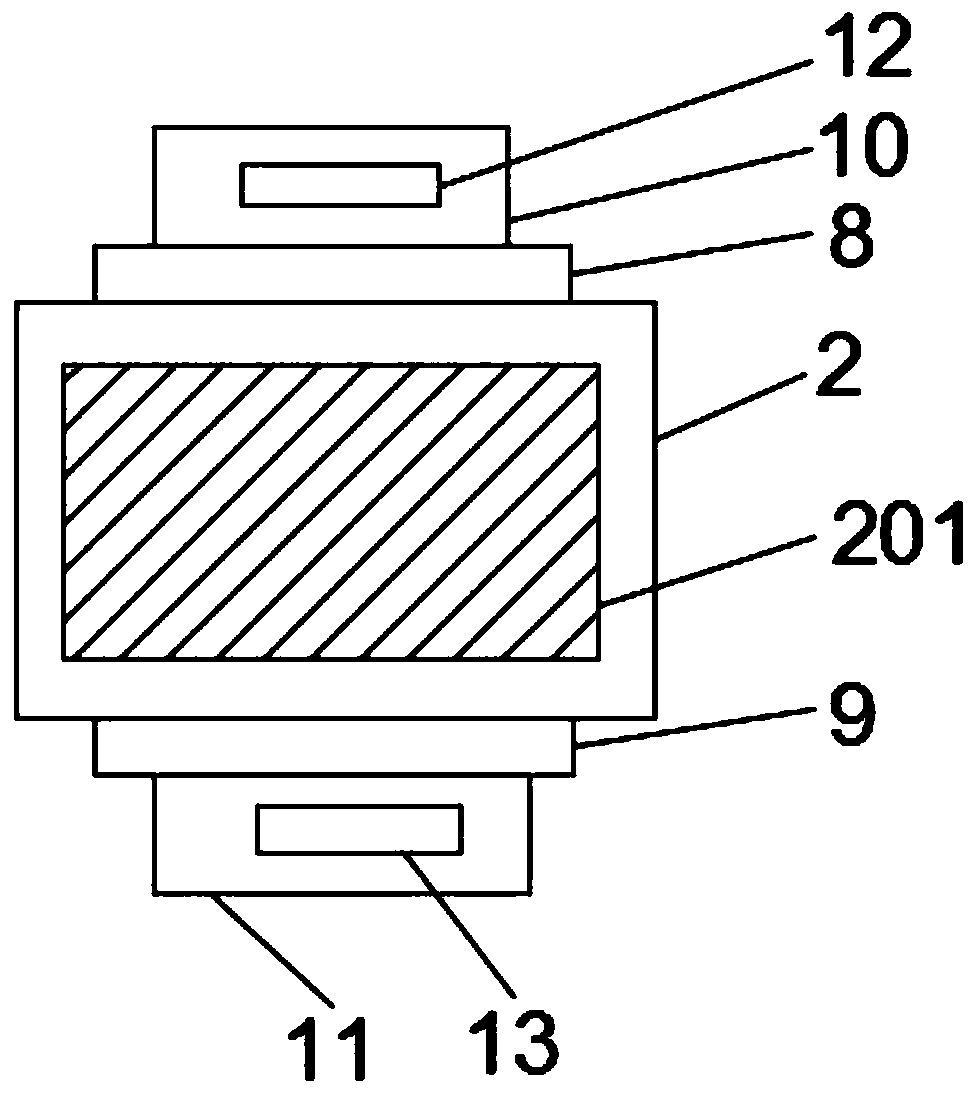

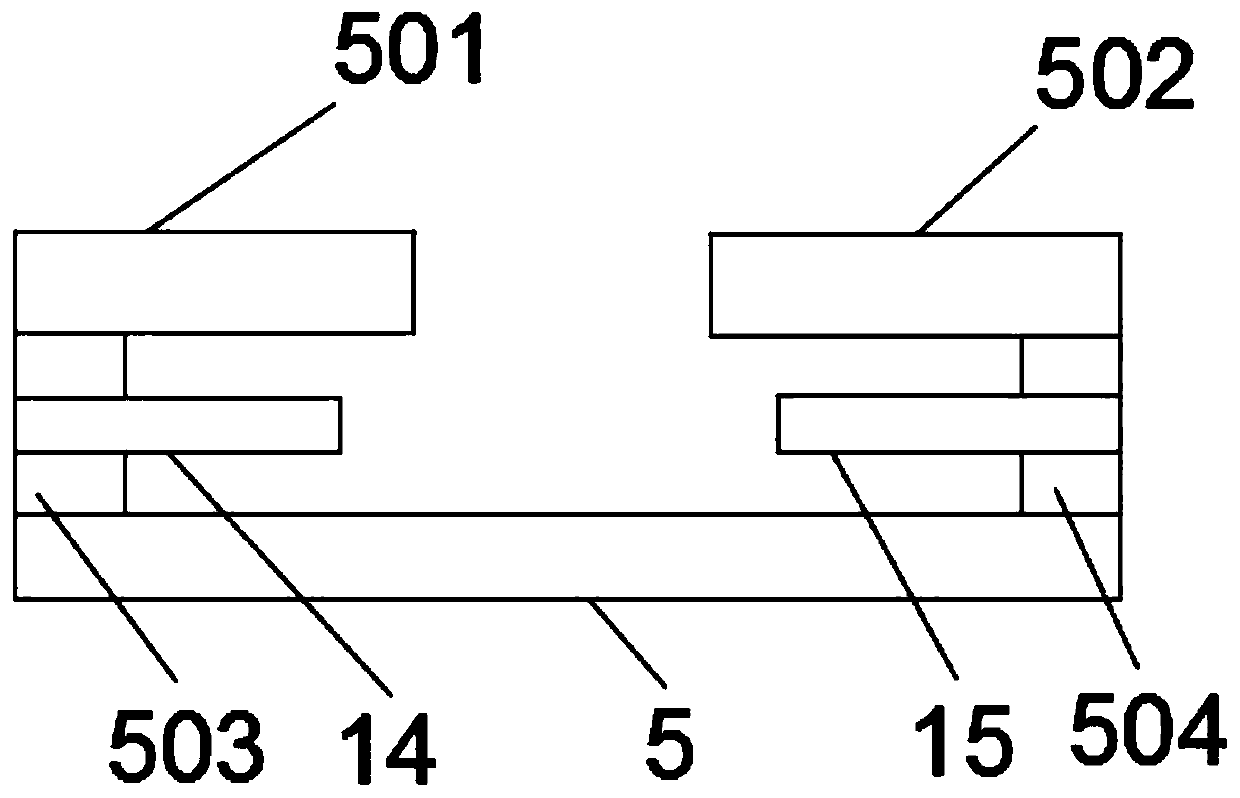

[0035] Such as Figure 1-5 As shown, a prefabricated demolition-free floor composite slab includes a composite slab main body 1, one side of the composite slab main body 1 is movably installed with a limited fixed block 2, and the other side of the composite slab main body 1 is movably installed with several A splint 24, the side of the limiting and fixing block 2 away from the laminated plate main body 1 is provided with a fixing groove 4, the upper surface of the limiting and fixing block 2 is provided with a fixing hole 3, and the lower surface of the laminated plate main body 1 Several limiting slots 5 are provided, and the outer surface of the laminated plate main body 1 is provided with several grooves 6, and the inner surface of the groove 6 is movably installed with several steel bar trusses 7, and the limiting and fixing block 2 The lower surface is provided with a friction block 201;

[0036]One side of the limiting fixed block 2 is fixedly installed with a first cl...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that the preparation process of the water reducing agent is as follows:

[0054] S1: In parts by weight, 6 parts of diatomite, 3 parts of dihydrate gypsum, 3 parts of triethanolamine and 8 parts of water are sealed and ball-milled to obtain a mixture for subsequent use;

[0055] S2: Add 10 parts of water and 2 parts of acrylamide to the reaction kettle, stir until completely dissolved, add 5 parts of 25% aqueous hydrogen peroxide solution and the mixture obtained in step S1, and then add 2 parts of 25% acrylic acid aqueous solution dropwise in sequence , 2 parts of 1.5% mass concentration of mercaptopropionic acid aqueous solution and 3 parts of mass concentration of 25% ferrous sulfate aqueous solution;

[0056] S3: Add 2 parts of 35% sodium hydroxide aqueous solution to adjust the pH to 6 to obtain the water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com