Fe-Mn-Ni-Cr four-component high-entropy alloy

A fe-mn-ni-cr, high-entropy alloy technology, applied in the field of high-entropy alloys, can solve the problems of low room temperature strength and high production cost, and achieve the effects of improving mechanical properties, small difference in atomic radius, and improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

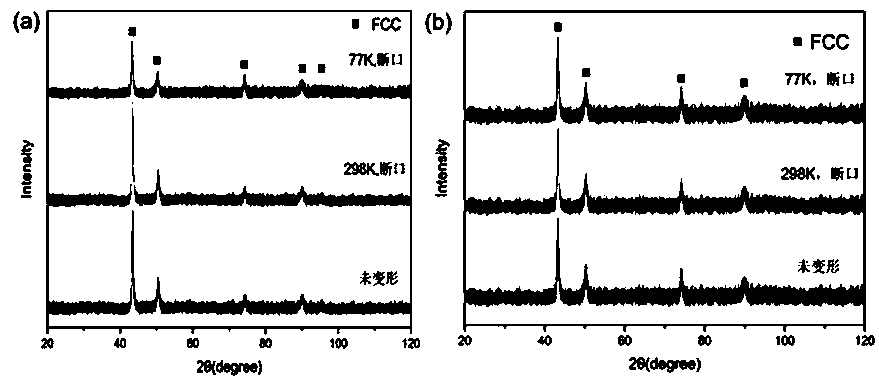

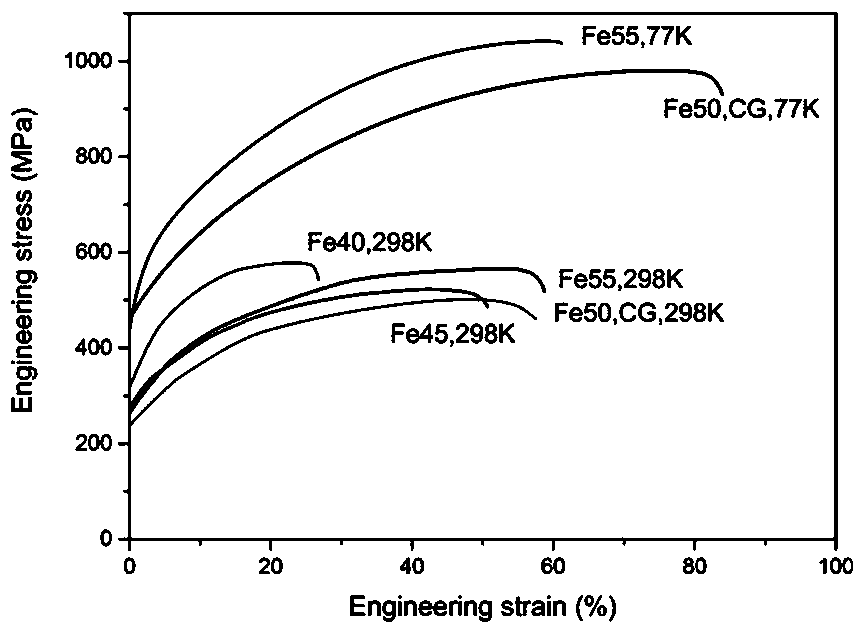

[0035] A Fe-Mn-Ni-Cr four-component high-entropy alloy, the alloy expression is Fe 55 mn 20 Ni 10 Cr 15 , denoted as S-1. As a more detailed example, its preparation method and related tests include the following steps:

[0036] (1) Batching: select Fe with a purity of 99.9wt%, Mn with a purity of 99wt%, Ni with a purity of 99.99wt%, and Cr with a purity of 99.99wt%, carry out the ingredients according to the above alloy expression, before weighing the raw materials , remove impurities such as oxide films on the surface of raw materials with sandpaper or a grinder, and then put the raw materials Fe, Ni and Cr into a beaker filled with absolute ethanol, perform ultrasonic cleaning for 250S, and then completely dry them with a hair dryer. Mn was washed with dilute nitric acid with a volume fraction of 5% to remove scale, followed by two washes in absolute ethanol, and then completely dried with a hair dryer;

[0037] (2) Melting master alloy and suction casting: In the vacu...

Embodiment 2

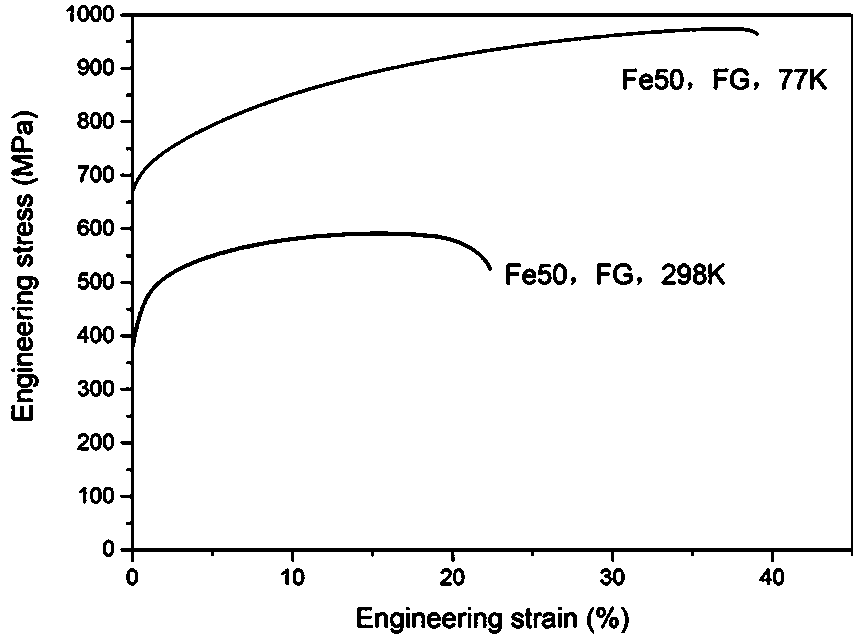

[0043] A Fe-Mn-Ni-Cr four-component high-entropy alloy, the alloy expression is Fe 50 mn 25 Ni 10 Cr 15 , denoted as S-2. As a more detailed example, its preparation method and related tests include the following steps:

[0044] (1) Batching: select Fe with a purity of 99.9wt%, Mn with a purity of 99wt%, Ni with a purity of 99.99wt%, and Cr with a purity of 99.99wt%, carry out the ingredients according to the above alloy expression, before weighing the raw materials , remove impurities such as oxide films on the surface of raw materials with sandpaper or a grinder, and then put the raw materials Fe, Ni and Cr into a beaker filled with absolute ethanol, perform ultrasonic cleaning for 300S, and then completely dry them with a hair dryer. Mn was washed with dilute nitric acid with a volume fraction of 5% to remove scale, followed by two washes in absolute ethanol, and then completely dried with a hair dryer;

[0045] (2) Melting master alloy and suction casting: In the vacu...

Embodiment 3

[0052] A Fe-Mn-Ni-Cr four-component high-entropy alloy, the alloy expression is Fe 50 mn 25 Ni 10 Cr 15 , denoted as S-3. As a more detailed example, its preparation method and related tests include the following steps:

[0053] (1) Batching: select Fe with a purity of 99.9wt%, Mn with a purity of 99wt%, Ni with a purity of 99.99wt%, and Cr with a purity of 99.99wt%, carry out the ingredients according to the above alloy expression, before weighing the raw materials , remove impurities such as oxide films on the surface of raw materials with sandpaper or a grinder, and then put the raw materials Fe, Ni and Cr into a beaker filled with absolute ethanol, perform ultrasonic cleaning for 240S, and then completely dry them with a hair dryer. Mn was washed with dilute nitric acid with a volume fraction of 5% to remove scale, followed by two washes in absolute ethanol, and then completely dried with a hair dryer;

[0054] (2) Melting master alloy and suction casting: In the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com