Peculiar-smell-free high-adhesion polyurethane composition, and preparation method and equipment thereof

A polyurethane and composition technology, applied in the field of polyurethane preparation, to achieve the effects of increasing the average molecular weight, eliminating peculiar smell, and facilitating industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

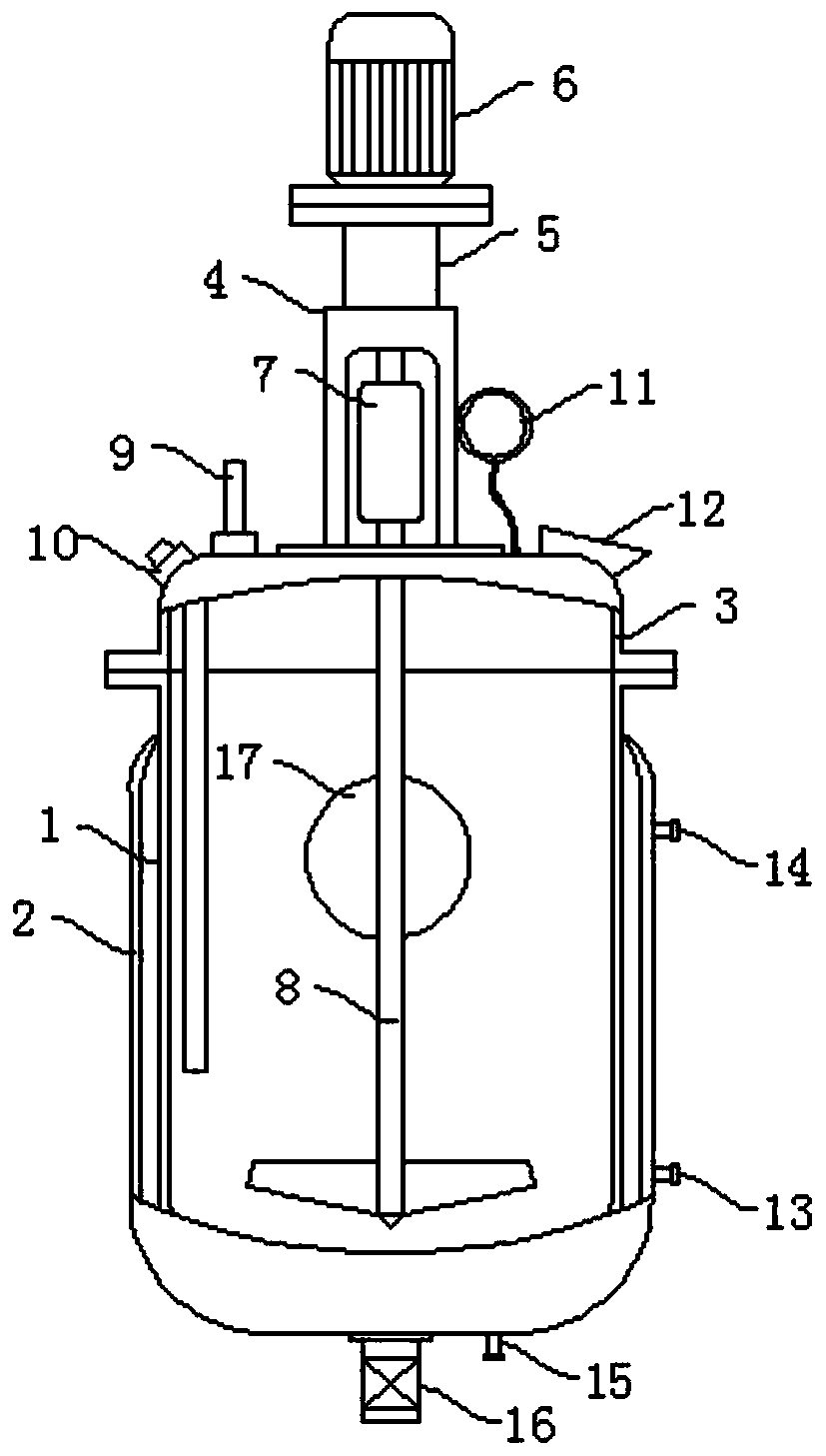

Image

Examples

Embodiment 1

[0037]The odorless high-adhesion polyurethane composition provided by the embodiment of the present invention contains 100 parts of polymer polyether polyol, 20-40 parts of polyisocyanate, 2-5 parts of crosslinking agent, and 1-5 parts of foaming agent. 5 parts, catalyst: 1-2 parts, defoamer with an average molecular weight of 800-1200: 0.5-2 parts.

[0038] In this embodiment, it is specifically prepared from the following components by weight:

[0039] Polyether polyol: 100 parts, diisocyanate: 20 parts, crosslinking agent: 3 parts, foaming agent: 3 parts, catalyst: 1.5 parts, defoamer with an average molecular weight of 1000: 1.5 parts.

[0040] Wherein, the catalyst is diethanolamine, and the catalyst can implant reactive -OH groups.

[0041] Wherein, the crosslinking agent is any one or more of glycerol, trimethylol, and propane.

[0042] The present invention solves the insolubility of high molecular weight polyether and low molecular weight polyether by adding high mo...

Embodiment 2

[0057] The non-odor type high-adhesion polyurethane composition, preparation method and equipment provided in this embodiment are basically the same as in Example 1, except that:

[0058] In this embodiment, it is specifically prepared from the following components by weight:

[0059] Polyether polyol: 100 parts, diisocyanate: 30 parts, crosslinking agent: 3 parts, foaming agent: 3 parts, catalyst: 1.5 parts, defoamer with an average molecular weight of 1000: 1.5 parts.

Embodiment 3

[0061] The non-odor type high-adhesion polyurethane composition, preparation method and equipment provided in this embodiment are basically the same as in Example 1, except that:

[0062] In this embodiment, it is specifically prepared from the following components by weight:

[0063] Polyether polyol: 100 parts, diisocyanate: 40 parts, crosslinking agent: 3 parts, foaming agent: 3 parts, catalyst: 1.5 parts, defoamer with an average molecular weight of 1000: 1.5 parts.

[0064] The non-odor type high-adhesion polyurethane composition, preparation method and equipment provided by the present invention solve the problems of sufficient reaction between materials, provide bonding performance and eliminate odor by synchronously improving material components, processes and equipment, and improve Strengthen the strength of the material and make it react fully and thoroughly, so as to eliminate the peculiar smell caused by the insufficient reaction of raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com