AMT gear shifting process control method

A technology of process control system and gear shifting motor, which is applied in the direction of control drive, control device, transmission device control, etc. It can solve the problems of combined gear shift top teeth, long control time, and long shifting time, so as to improve the overall vehicle performance. The effect of power performance, shortened shift time, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

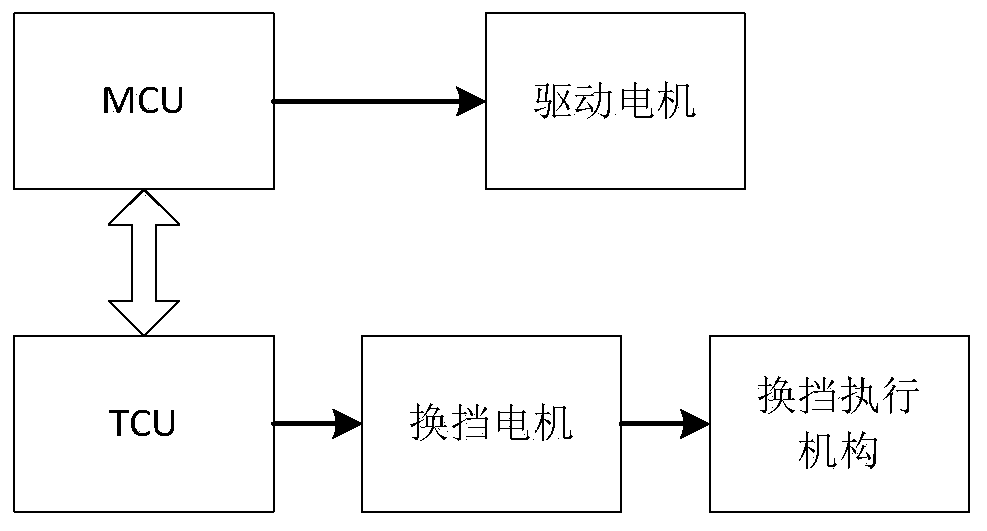

[0025] The minimum carrier architecture of the control method is as figure 1 As shown, it includes two independent control units - TCU (AMT controller) and MCU (motor controller). The TCU is connected to the shift motor through the wire harness. The shift motor is installed on the shift actuator. The driving motor is connected, and the data transmission and command transmission are carried out between the TCU and the MCU through the CAN bus.

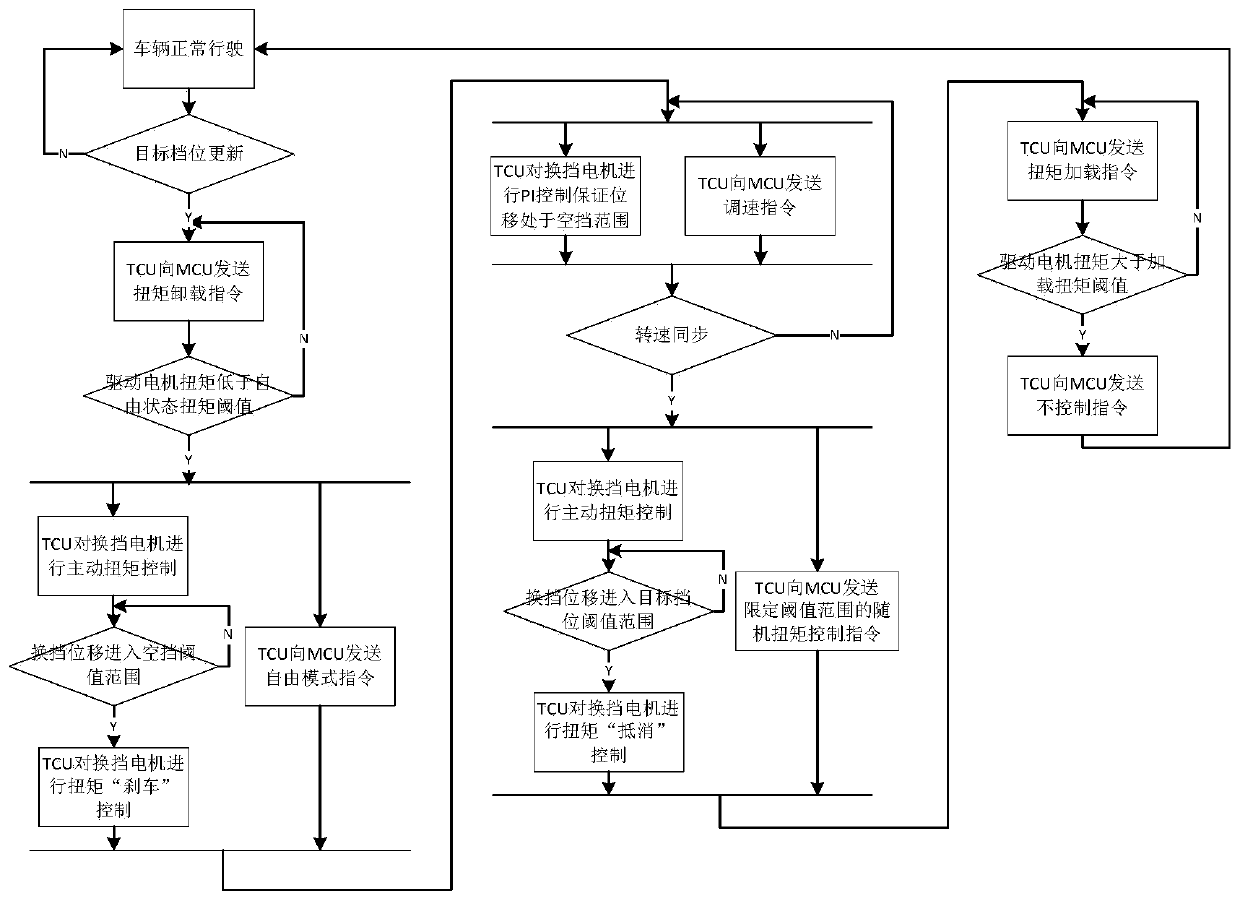

[0026] The control method adopts the following steps:

[0027] Step 1. The driver drives the vehicle to drive normally by manipulating the accelerator pedal and the brake pedal;

[0028] Step 2. During normal driving, the TCU continuously judges whether to update the target gear according to the collected signals such as vehicle speed, accelerator pedal opening, and vehicle acceleration;

[0029] Step 3. When the target gear is updated, the TCU sends a torque unloading command to the MCU, and then judges whether the drive motor torque ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com