Control method and control device for thermal management device of automobile, and storage medium

A control method and a technology for thermal management, which are applied in the fields of control methods for thermal management devices, storage media, and control devices, and can solve problems such as few operating modes and inability to meet user needs well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

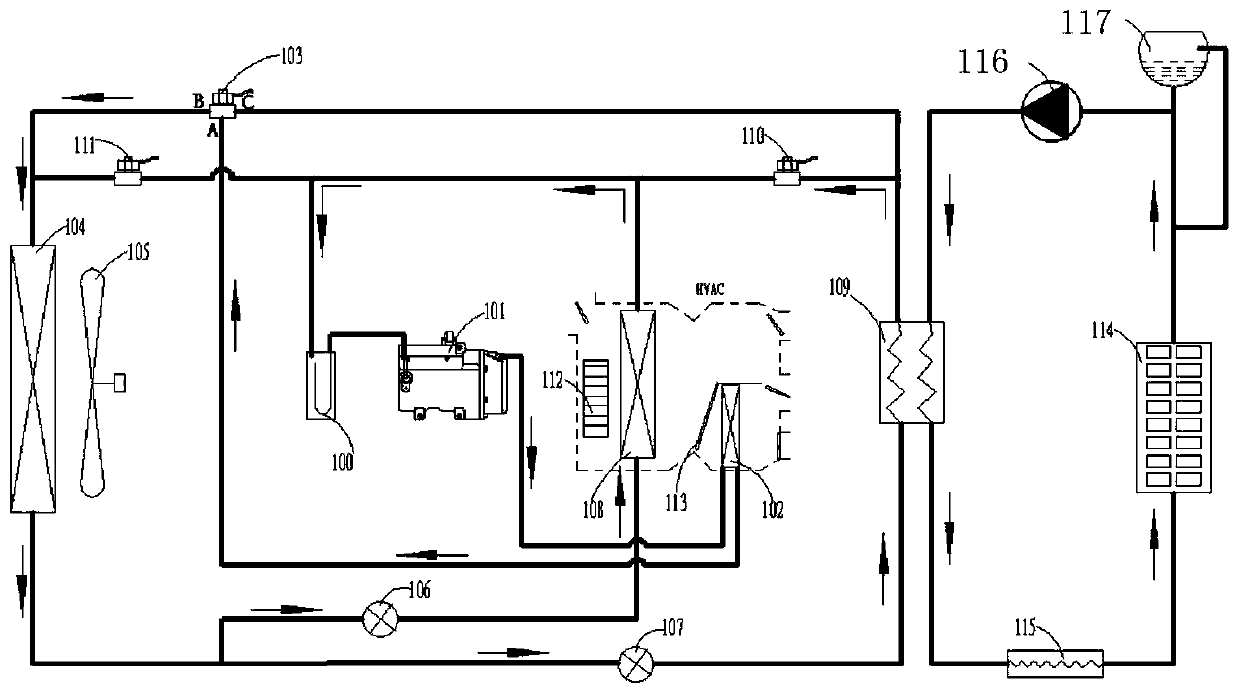

[0114] This embodiment relates to a thermal management device, image 3 and Figure 4 Schematic diagram of the structure of the thermal management device.

[0115] The device includes a vapor-liquid separator 100, a compressor 101, an inner condenser 102, an electromagnetic three-way valve 103, an outer heat exchanger 104, an outer fan 105, a first throttling element 106, a second throttling element 107, an inner evaporator 108, intermediate heat exchanger 109, first electromagnetic two-way valve 110, second electromagnetic two-way valve 111, blower 112, heating and cooling damper 113, battery pack heat exchange terminal 114, PTC electric heater 115, water pump 116 and expansion tank 117 , the specific connection relationship of each component is as follows image 3 and Figure 4 As shown, one end of the vapor-liquid separator 100 is connected to one end of the compressor 101, the other end of the compressor 101 is connected to one end of the inner condenser 102, and the ot...

Embodiment 3

[0135] This embodiment relates to a flow chart of the control method of the thermal management device in Embodiment 1, as shown in Figure 6 As shown, the method specifically includes:

[0136] ① Firstly, in S202, it is determined whether there is a defogging demand in the cabin. Generally, the defogging demand is formed by the driver setting the defogging mode through the operation panel;

[0137] If there is a need for demisting, enter step S203 to further determine whether the battery needs to be cooled:

[0138] If the battery needs to be cooled, go to S205 to judge the current outer ring condition. The judgment of the outer ring here is mainly to determine whether to use the cooling mode or the heating mode for the cabin defogging. The idea is: use cooling at medium and high temperatures (Tout≥M℃) Mode, that is to execute the third operation mode of S213: battery cooling + cabin cooling co-operation; at low temperature (Tout

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com