A kind of harness threading equipment

A technology for pipe threading and equipment, applied in the field of pipe threading, can solve problems such as inconvenience in use, and achieve the effects of convenient use, strong practicability and saving processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

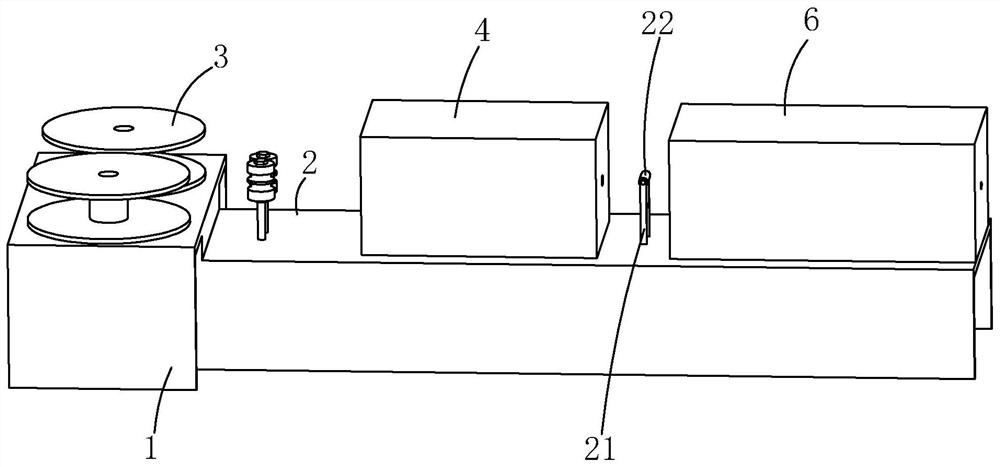

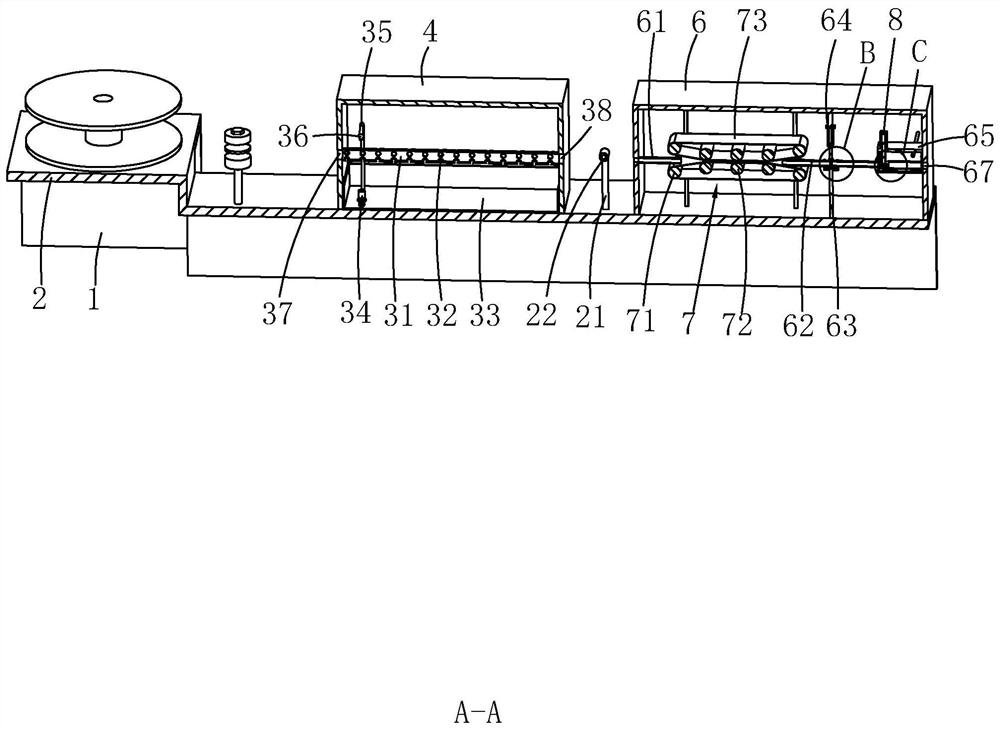

[0045] refer to figure 1 and figure 2 , is a wire harness threading device disclosed in the present invention, which includes a frame body 1 and a workbench 2 located on the frame body 1. On the surface of the workbench 2, two sets of winding posts 3 wound with wire harnesses are connected in rotation, and the winding posts 3 One side is provided with a lubrication box 4 on the workbench 2, refer to image 3 The side of the lubricating box 4 away from the winding post 3 is provided with a driving assembly 7 for driving the movement of the wire harness. There is a rotary column 22 which can be contacted with the wiring harness, and an annular wire groove is opened on the rotary column 22, and the annular wire groove is arranged along the circumferential direction of the rotary column 22, which is not shown in the figure.

[0046] refer to image 3 and Figure 4 The outer periphery of the drive assembly 7 is covered with a casing 6, and a first hollow wire tube 61 and a sec...

Embodiment 2

[0053] A method for using a wire harness threading device, comprising the following steps:

[0054]Step 1: Cut the casing. According to the requirements of the casing and the wiring harness, mark the casing with a measuring tool, then cut the casing with a cutting machine, and transfer the casing to a nearby installation by a transfer vehicle. hole 67;

[0055] Step 2: wiring harness lubrication, add lubricating oil to the oil tank 33, adjust the oil pump 34, the oil pump 34 pumps the lubricating oil in the oil tank 33 to the nozzle 36 through the pipeline 35, adjust the nozzle 36, spray the lubricating oil, and the lubricating oil passes through The flow hole 32 enters the third hollow wire tube 31 to lubricate the wiring harness in the third hollow wire tube 31;

[0056] Step 3: Initial installation of the wire harness, the end of the wire harness wound on the winding column 3 is inserted into the third hollow wire tube 31 through the wire inlet hole 37, and then passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com