Hydrate-based particulate matter/waste gas synergistic removal system and method

A hydrate and particulate matter technology, applied in the field of hydrate-based particulate matter/exhaust gas collaborative removal system, can solve the problems of ineffective capture of particulate matter/coking exhaust gas, etc., to achieve resource treatment, reduce emissions, and one-time investment Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

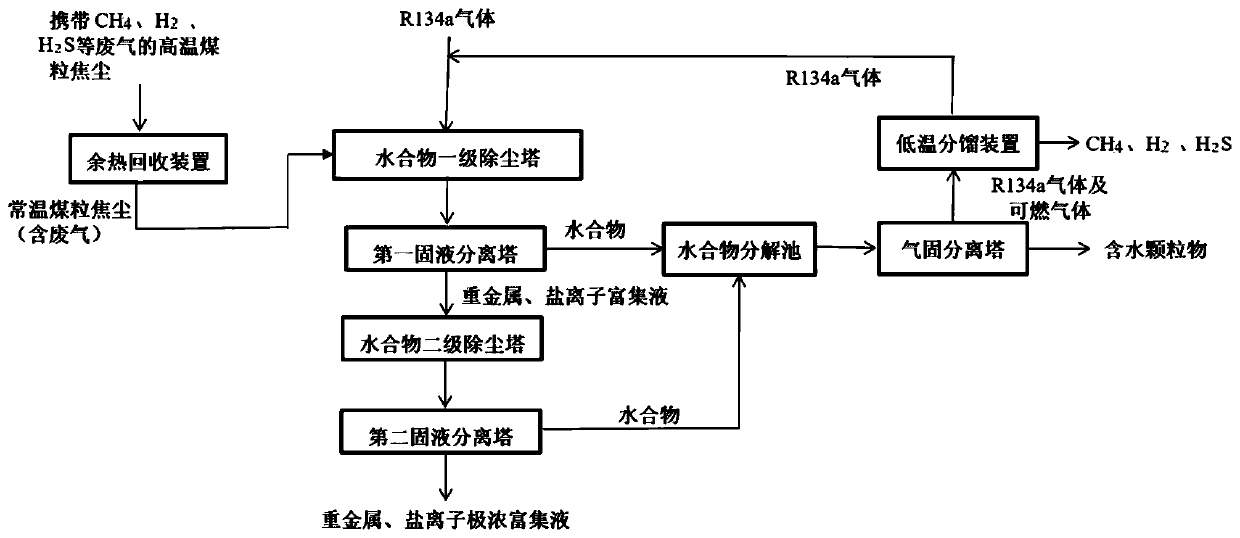

[0031] This embodiment is a hydrate-based method for synergistic removal of particulate matter / coking waste gas in iron and steel coking plants, combining figure 1 , the process is as follows:

[0032] Step 1: Carrying CH produced in the production process of the steel coking plant 4 、H 2 、H 2 The high-temperature coal particles and coke dust of waste gas such as S are transported to the waste heat recovery device, and the temperature is lowered to obtain CH 4 、H 2 、H 2 Normal temperature coal coke dust of waste gas such as S;

[0033] Step 2: will contain CH 4 、H 2 、H 2 The normal temperature coal particles and coke dust of waste gas such as S are transported to the hydrate primary dedusting tower, and the CH 4 、H 2 、H 2 Normal temperature coal particles and coke dust of waste gas such as S are humidified in the water pool in the tower to obtain wet gas-containing particles, and then R134a gas is passed into the hydrate primary dedusting tower to form in the tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com