Mining ceramic filter plate cleaning device and using method thereof

A technology of ceramic filter and cleaning device, which is applied in the direction of cleaning method using liquid, cleaning method using gas flow, cleaning method and utensils, etc., which can solve the problem of high cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

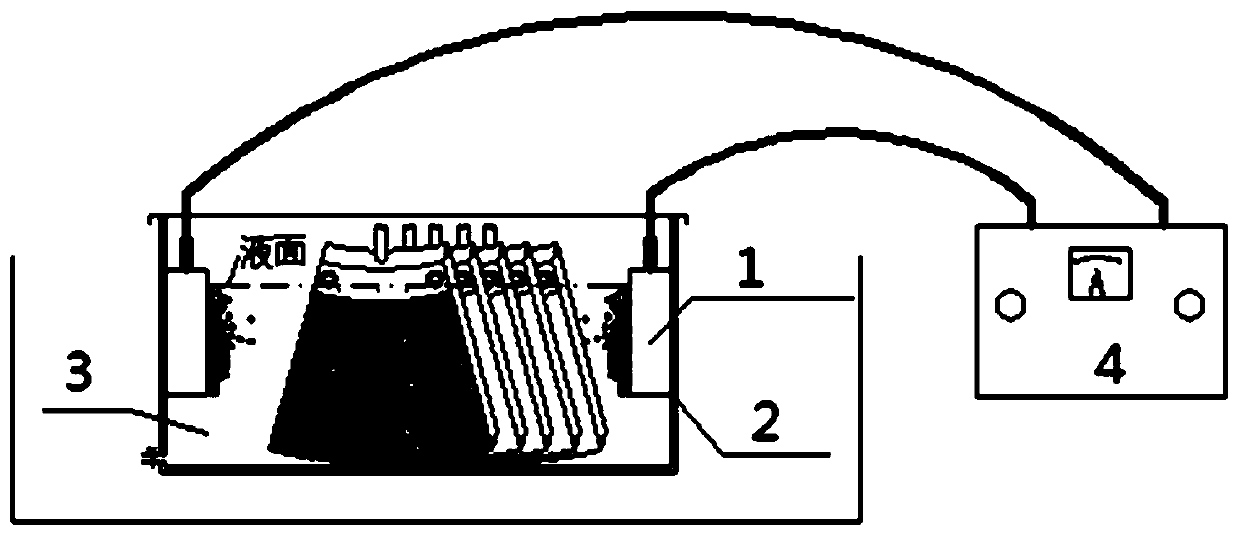

[0019] Such as Figure 1-2 As shown, a filter plate cleaning device for a mining ceramic filter includes an ultrasonic oscillation device, a soaking device and a recoil device; the ultrasonic oscillation device includes an ultrasonic transducer 1 and an ultrasonic signal generator 4; the soaking device A cleaning tank 2 is included, and the concentrated hydrochloric acid 3 with a mass fraction of 36% is filled in the cleaning tank 2;

[0020] The ultrasonic transducer 1 is arranged on the inner wall surface of the cleaning tank 2 . The ultrasonic transducer 1 is electrically connected with the ultrasonic signal generator 4 .

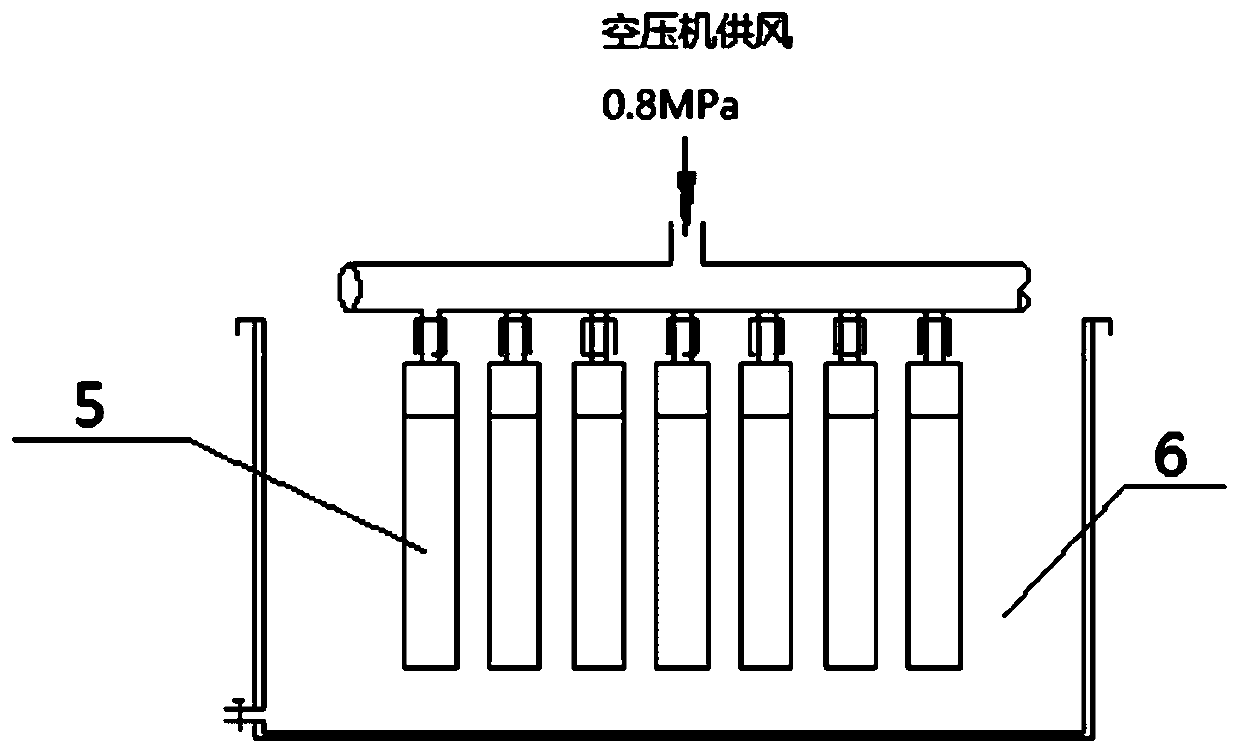

[0021] The recoil gas device comprises a tank body of the recoil gas device and a pressure tank, an air compressor and connecting hoses connected in sequence. Clear water 6 is filled in the recoil air device. When recoil gas, the air compressor pressure is 0.8MPa.

[0022] Working principle: first put the waste ceramic filter plate 5 into the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com