Square power battery shell disassembling device

A power battery and shell technology, applied in the field of square power battery shell dismantling devices, can solve the problems of low dismantling efficiency, inner core structure damage, and high debris cost, so as to save manpower, avoid potential safety hazards, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

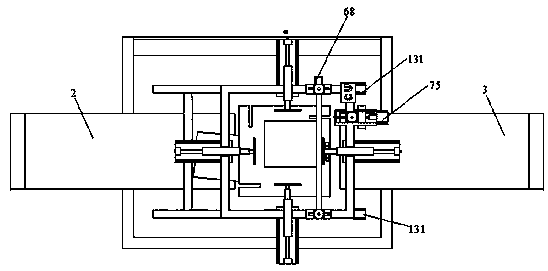

[0036] Attached below Figure 1-6 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0037] In order to improve the efficiency of dismantling the prismatic battery case and further ensure the safety of the dismantling process, a dismantling device for the prismatic power battery case is disclosed in this embodiment, and an import conveyor belt 2 and an export conveyor belt 3 are respectively provided on both sides of the frame 1 On the frame 1, a shift fork 4, a clamping mechanism 5, a horizontal cutting assembly 6 and a vertical cutting assembly 7 are sequentially arranged along the conveying direction of the conveyor belt, and an auxiliary transmission mechanism 8 is arranged at the bottom of the frame 1, and the frame 1 and The auxiliary transmission mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com