Processing technology of Porro combined prism

A processing technology and prism technology, applied in the field of Paul combined prism processing technology, can solve the problems of poor precision of Paul combined prism, low qualified rate of finished products, etc., and achieve the effect of reducing the scrap rate of materials, high qualified rate of finished products, and high product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

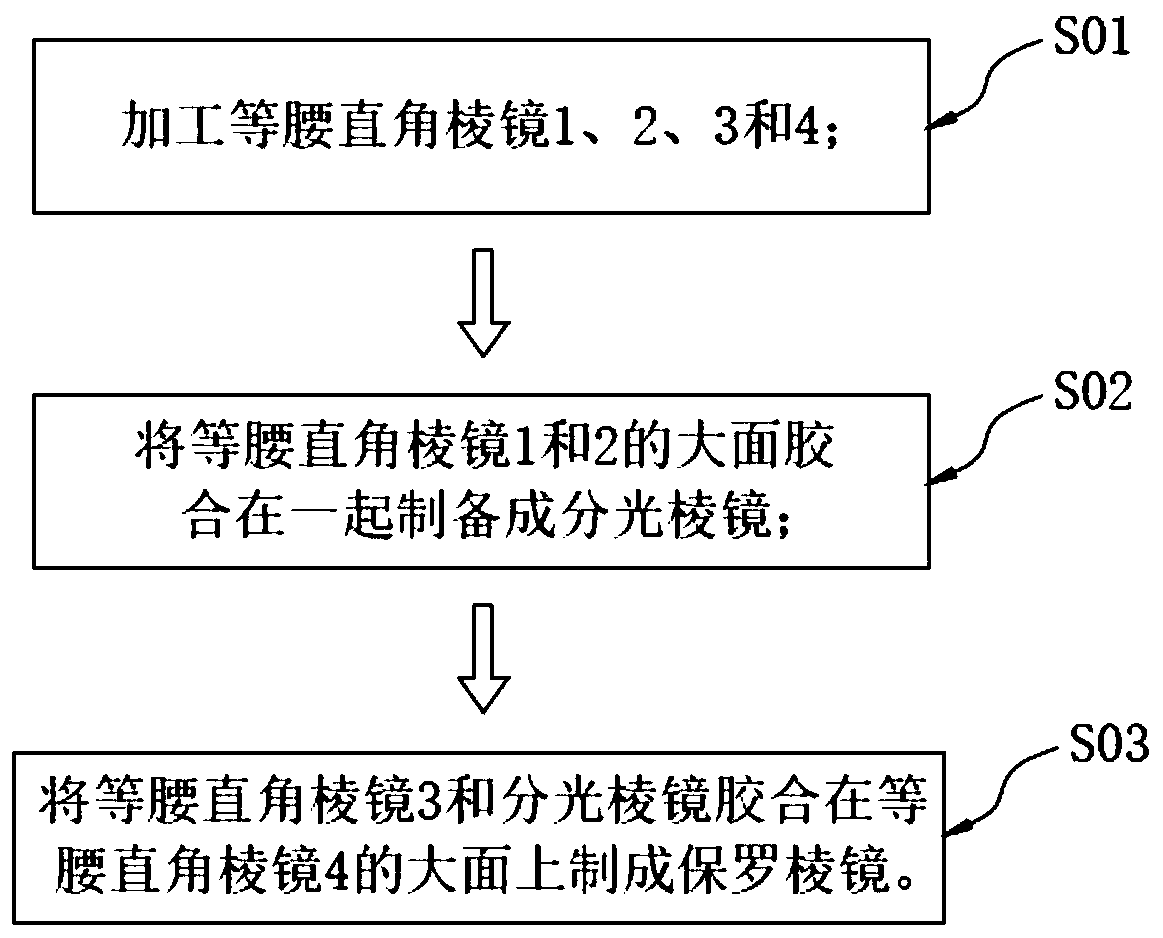

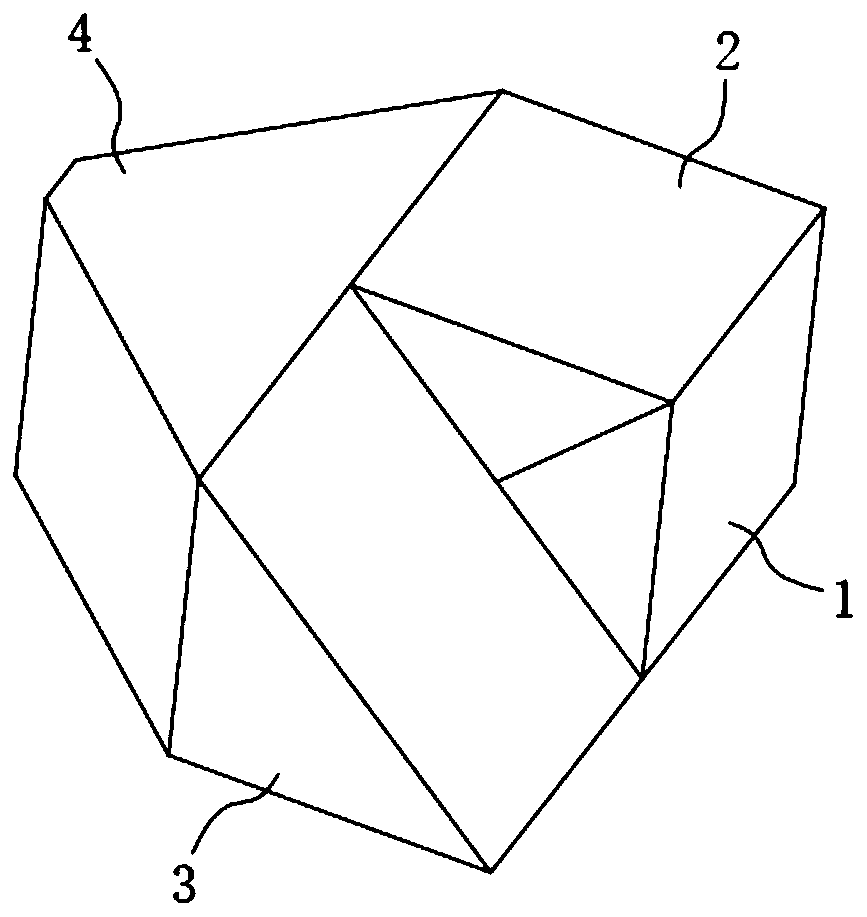

[0058] In this embodiment, a Paul combined prism processing technology, such as figure 2 As shown in the figure, the Paul combined prism is composed of isosceles right-angle prisms glued together. The isosceles right-angle prisms include isosceles right-angle prism I1, isosceles right-angle prism II2, isosceles right-angle prism III3 and isosceles right-angle prism IV4, processed Steps like figure 1 The specific steps are as follows:

[0059] S01, processing isosceles right-angle prism:

[0060] Ⅰ. Grinding and polishing areosceles right-angle prism Ⅰ1, isosceles right-angle prism Ⅱ2 and isosceles right-angle prism Ⅲ3, and isosceles right-angle prism Ⅳ4 with large side length of 10×20mm; The process parameters for controlling each of the isosceles right-angle prisms are: the precision of the 45° angle, the 90° angle and the tower difference are controlled within 8", and the perpendicularity of the large face and the two right-angled faces to the triangle side face is controlled wi...

Embodiment 2

[0068] In this embodiment, a Paul combined prism processing technology, the structure of the Paul combined prism is the same as that in embodiment 1, and the processing steps are as follows:

[0069] S01, processing isosceles right-angle prism:

[0070] Ⅰ. Grinding and polishing areosceles right-angle prism Ⅰ1, isosceles right-angle prism Ⅱ2 and isosceles right-angle prism Ⅲ3, and isosceles right-angle prism Ⅳ4 with large side length of 20×40mm; The process control of each of the isosceles right-angle prisms is: the precision of the 45° angle, the 90° angle and the tower difference are all controlled within 10", the perpendicularity of the large face and the two right-angle faces to the triangle side face is controlled within 30", and the size The tolerance is ±0.02mm; the surface flatness of the large surface is ≤1 / 10λ, and the surface finish is 15-20; the surface flatness of the two right-angled surfaces is ≤1 / 8λ, and the surface finish is 30-40;

[0071] Ii. Coating each of the i...

Embodiment 3

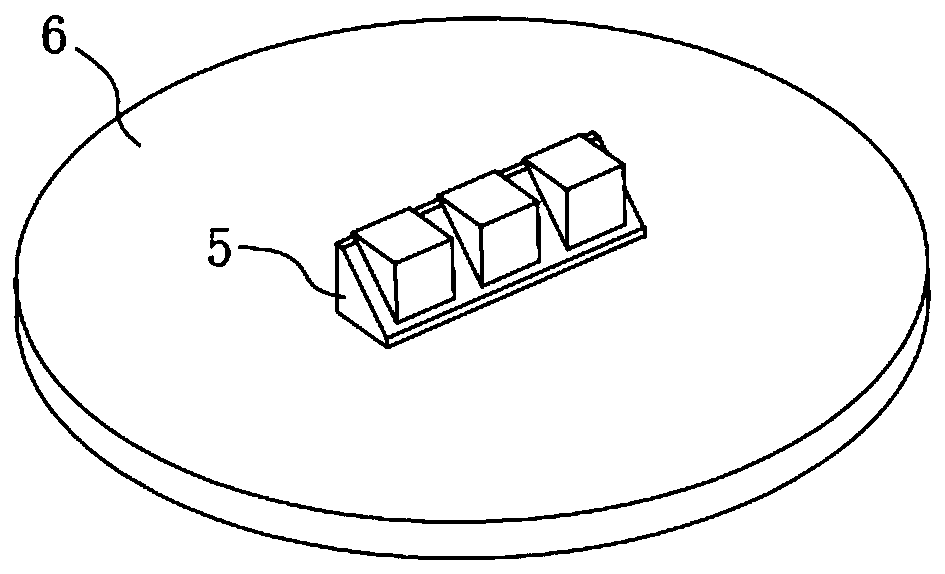

[0078] The Paul combined prism processing technology in this embodiment, the processing steps are basically the same as those in the first and second embodiments, and the difference and improvement are as follows: image 3 As shown in, the processing method of the isosceles right-angle prism is as follows:

[0079] Ⅰ. Glue the blank to the large surface of the triangular prism supporting body 5 with optical glue, keeping the large surface of the blank facing upward, and then apply the right-angled surface glue at the bottom of the triangular prism supporting body 5 to a circular tray with a diameter of 300mm 6, and then grind and polish the large surface of the blank;

[0080] Ⅱ. Wipe clean the processed large surface with a mixture of ethanol and ether = 1:3, and then apply the large surface of the blank to the large surface of the triangular prism body 5, and ensure that the right-angle side of the blank faces upwards. Then, the right-angled surface of the triangular prism leanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com