Surface acoustic wave device

A surface acoustic wave and surface orientation technology, applied in impedance networks, electrical components, etc., can solve problems such as hindering mass production, the substrate is limited to quartz, and no single crystal aluminum electrode film is proposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

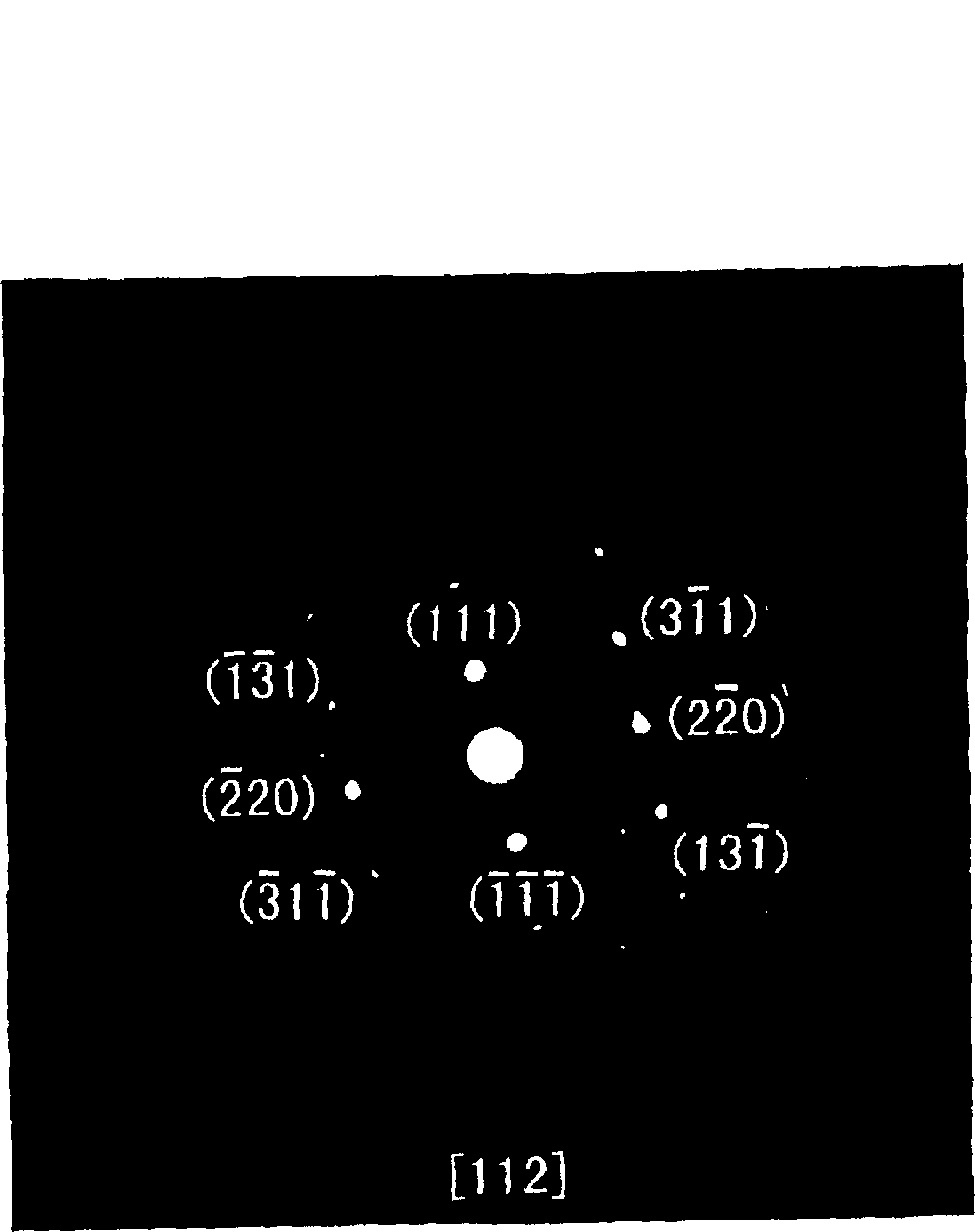

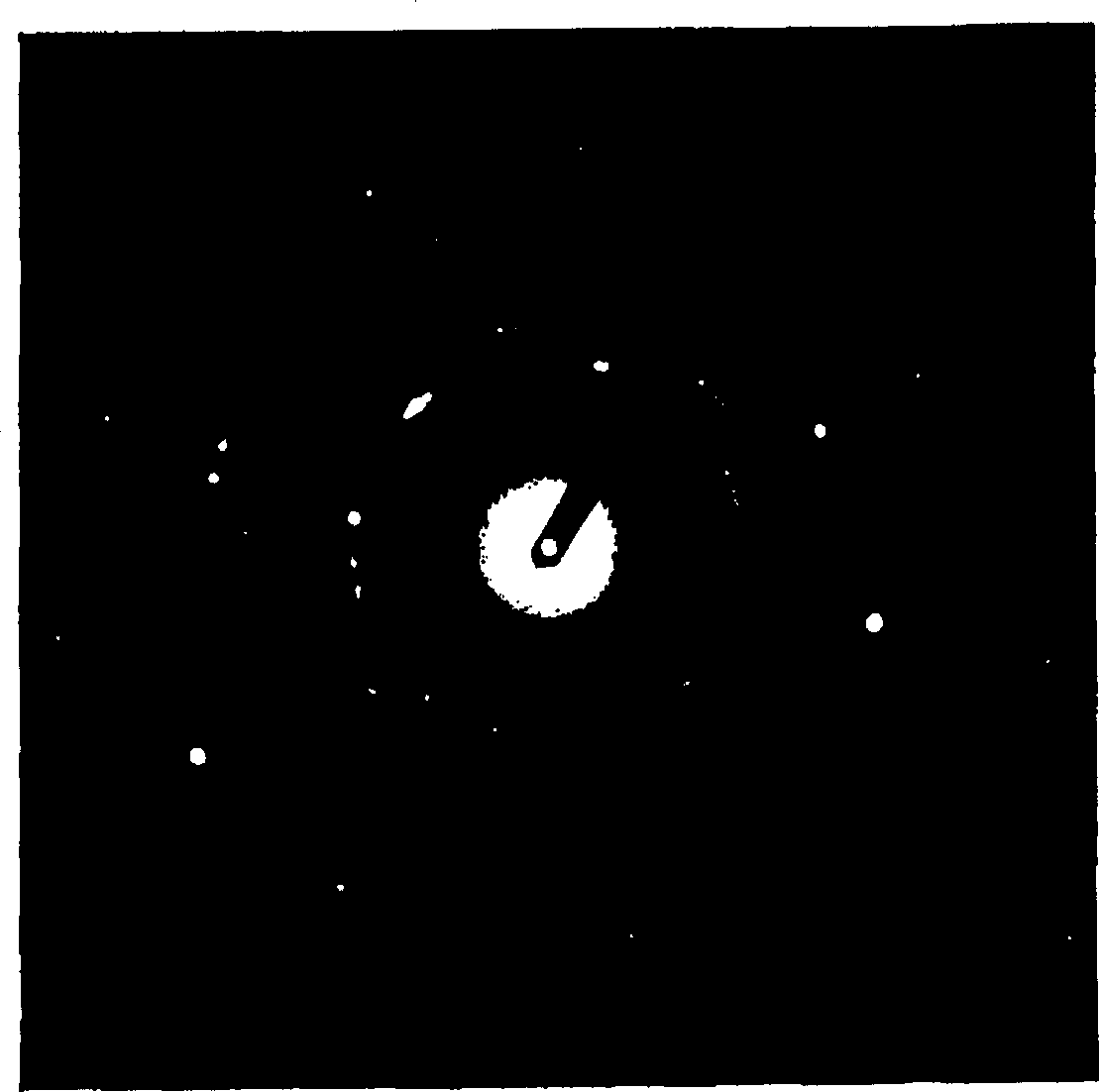

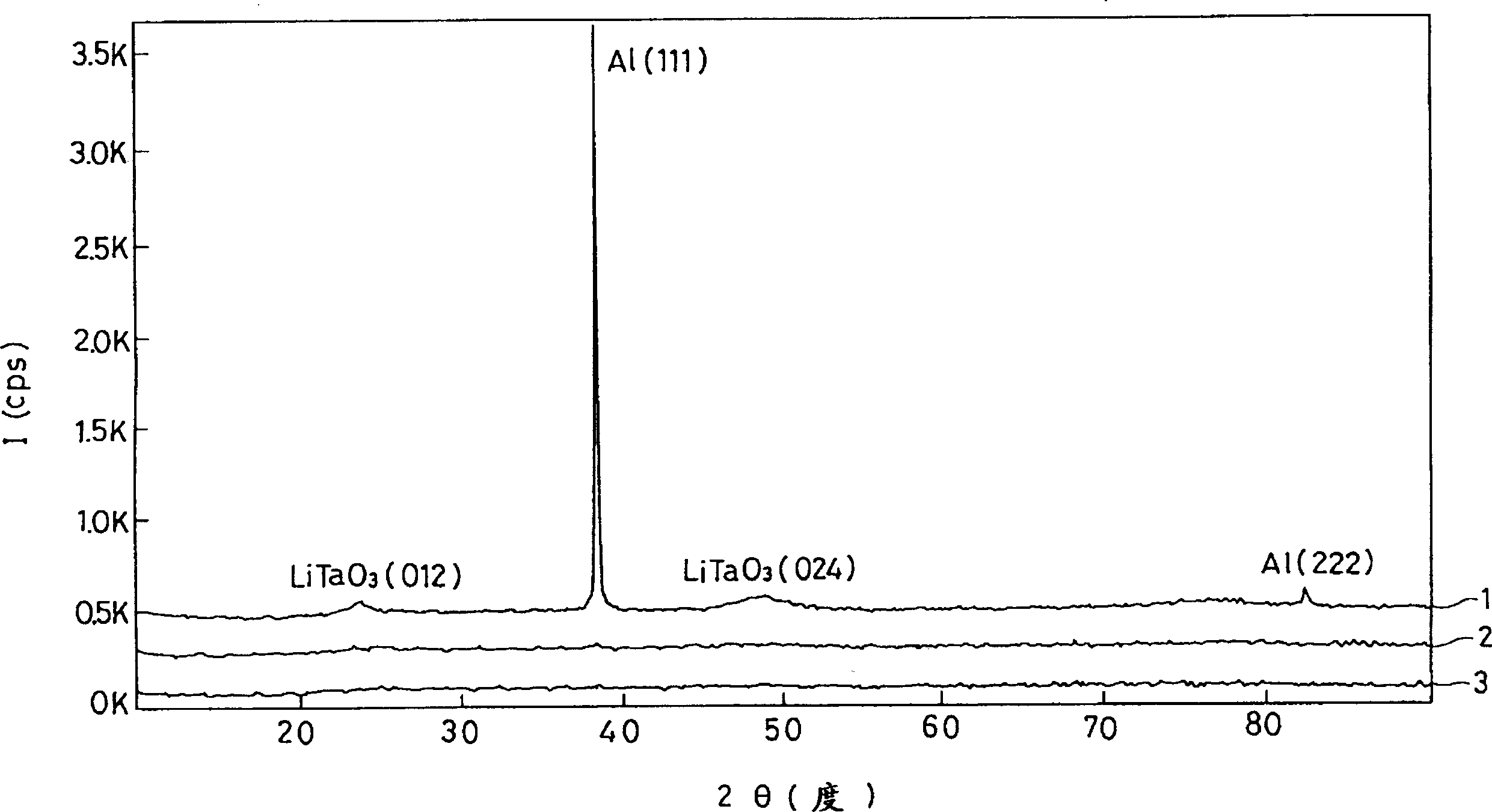

[0040] The present inventors conducted empirical studies in an attempt to form a single crystal aluminum film on a 36-degree-rotated Y-cut lithium tantalate substrate similar to that commonly used as a piezoelectric substrate for an RF band filter. As a result, the present inventors have found that increasing the cutting orientation for crystal cutting from the 36-degree rotation Y commonly used in the prior art to the larger angle side, i.e., 38-44 degree rotation Y, forms a titanium film On the substrate, and when an aluminum film is formed on the titanium film, the aluminum film becomes a single crystal film. In a SAW device using the thus formed aluminum single crystal film as an electrode film, the power durability of the electrode film is drastically improved.

[0041] The SAW device of the present invention includes a substrate having a surface and at least one pair of interdigital electrodes (or comb electrodes) formed on the surface of the substrate. The interdigitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com