Assembly type steel pipe tower outer sleeve type node

A technology of outer sleeve and steel pipe tower, applied in the field of steel structure, can solve the problems of complex damage form, unclear force transmission path, and difficulty in adapting to prefabricated steel structure, so as to reduce manual work, facilitate joint design, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

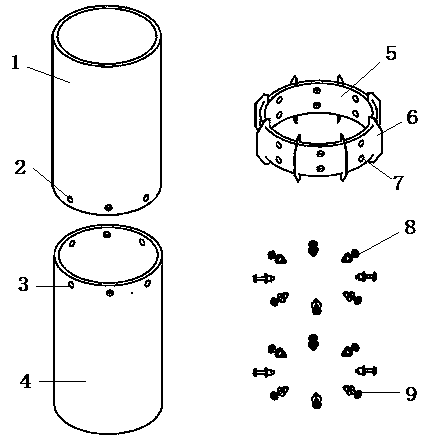

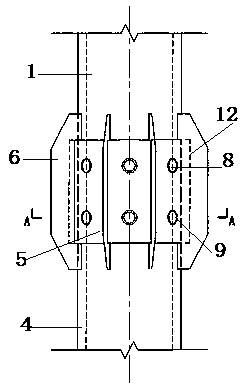

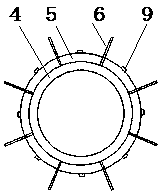

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as figure 2 and image 3 Shown: an assembled steel pipe tower outer sleeve type node; including connected upper main pipe 1 and lower main pipe 4, characterized in that it also includes outer sleeve 5 and several stiffeners 6; outer sleeve 5 is placed The periphery of the connecting end of the upper main pipe 1 and the lower main pipe 4 is fixedly connected with the upper main pipe 1 and the lower main pipe 4 through rivets; end face.

[0021] see figure 1 ; The lower side wall of the upper main pipe 1 is evenly distributed with rivet holes 2, the upper end side wall of the lower main pipe 4 is evenly distributed with the lower main pipe rivet holes 3, and the middle part of the side wall of the outer sleeve 5 is provided with upper and lower circles evenly distributed The outer sleeve rivet hole 7, the first rivet 8 connects the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com