Method for prolong service life of intermetallic compound and controlling deformation through laser shock processing

A technology of laser shock strengthening and intermetallic compounds, which is applied in the field of surface strengthening, can solve problems such as the improvement of vibration and finishing fatigue performance, the inapplicability of extrusion strengthening, and the large deformation of thin-walled parts, achieving huge military significance and economic benefits. Solve the problem of deformation control, the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] The carrier implemented in this embodiment is an intermetallic compound blade; the condition for implementing the present invention is a laser shock peening device with a programming function.

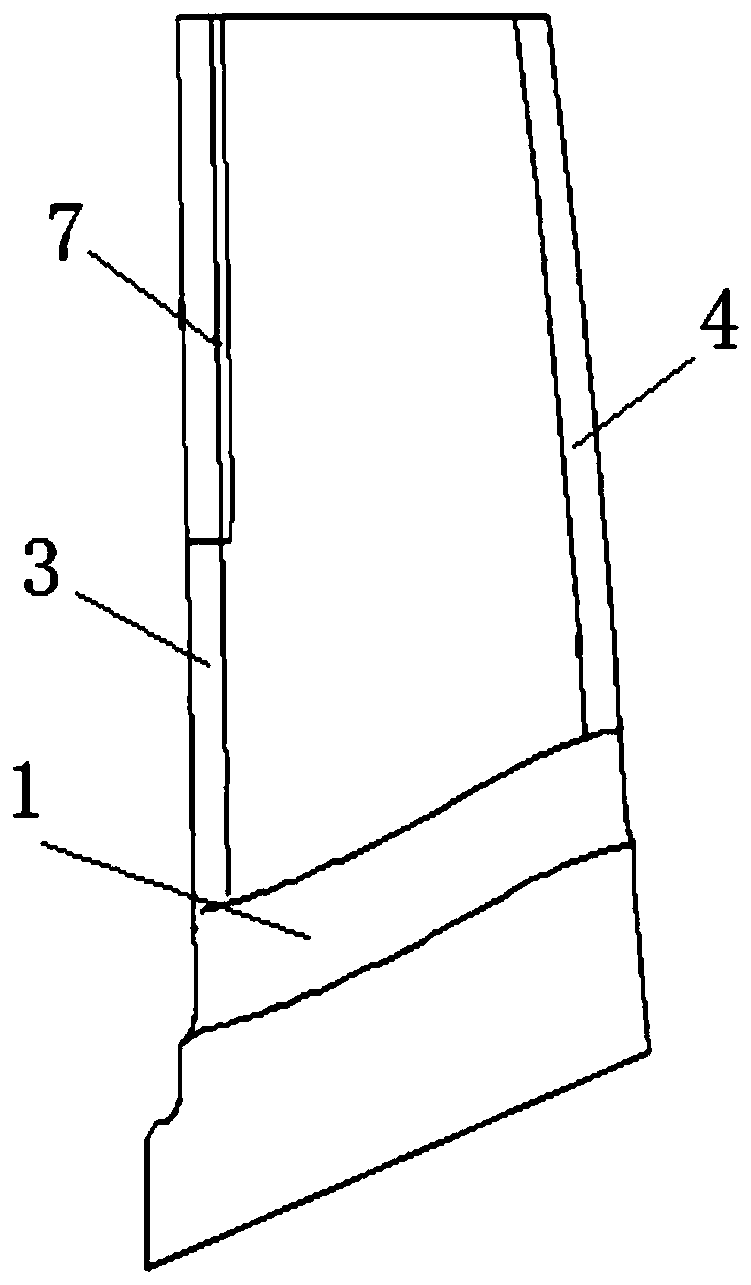

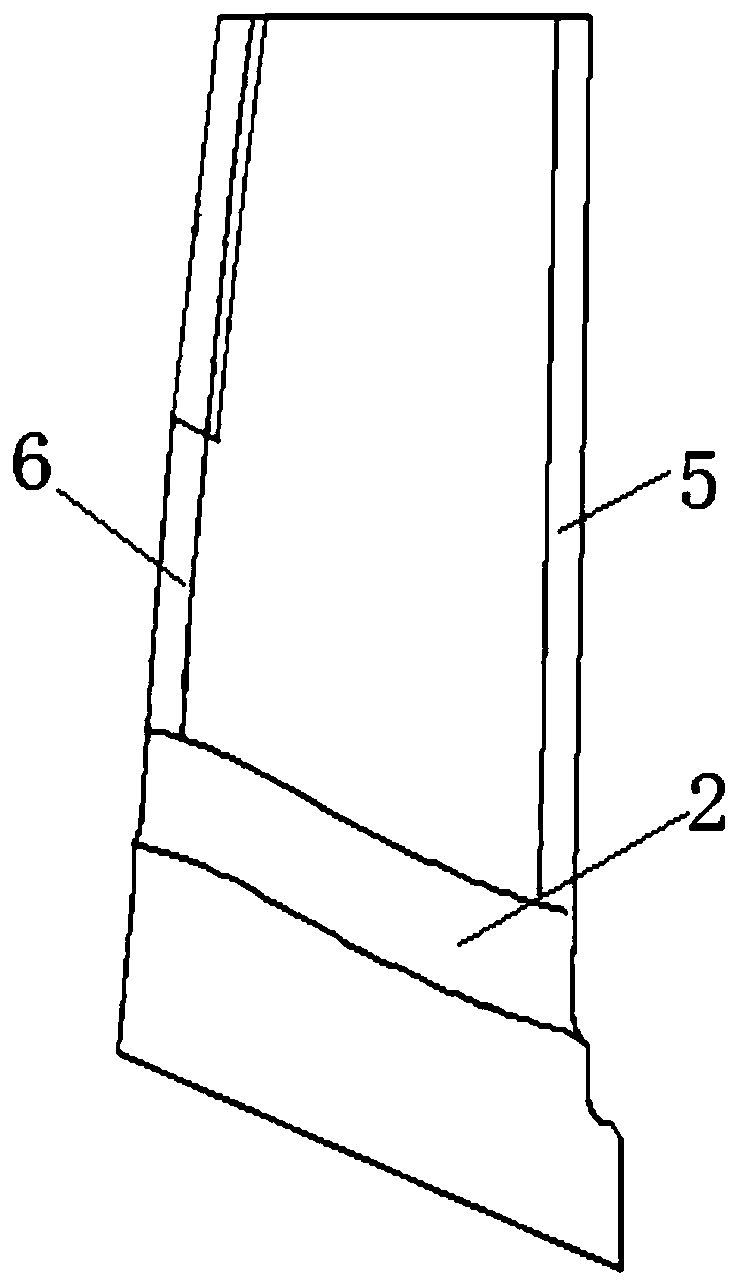

[0033] A method of laser shock strengthening of intermetallic compounds for life improvement and deformation control, such as Figure 1 to Figure 3 shown, including the following steps:

[0034] Step 1, parts clamping: clamp the blade tenon to the track robot fixture;

[0035] Step 2, parts cleaning: use silk cloth dipped in absolute ethanol to wipe the front and back sides of the blade to ensure no oil stains;

[0036] Step 3, the arrangement of the absorbing layer: the air intake edge 3 of the leaf basin, the exhaust edge 4 of the leaf basin, the air intake edge 5 of the leaf back, the exhaust edge 6 of the leaf back, the root of the leaf ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com