Composite material of core/shell structure having covalent organic framework, and preparation method and application thereof

A technology of covalent organic framework and composite materials, which is applied in the field of composite materials with core-shell structure of covalent organic framework and its preparation and application, can solve the problems of difficult separation and recovery, poor stability, etc. High stability and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

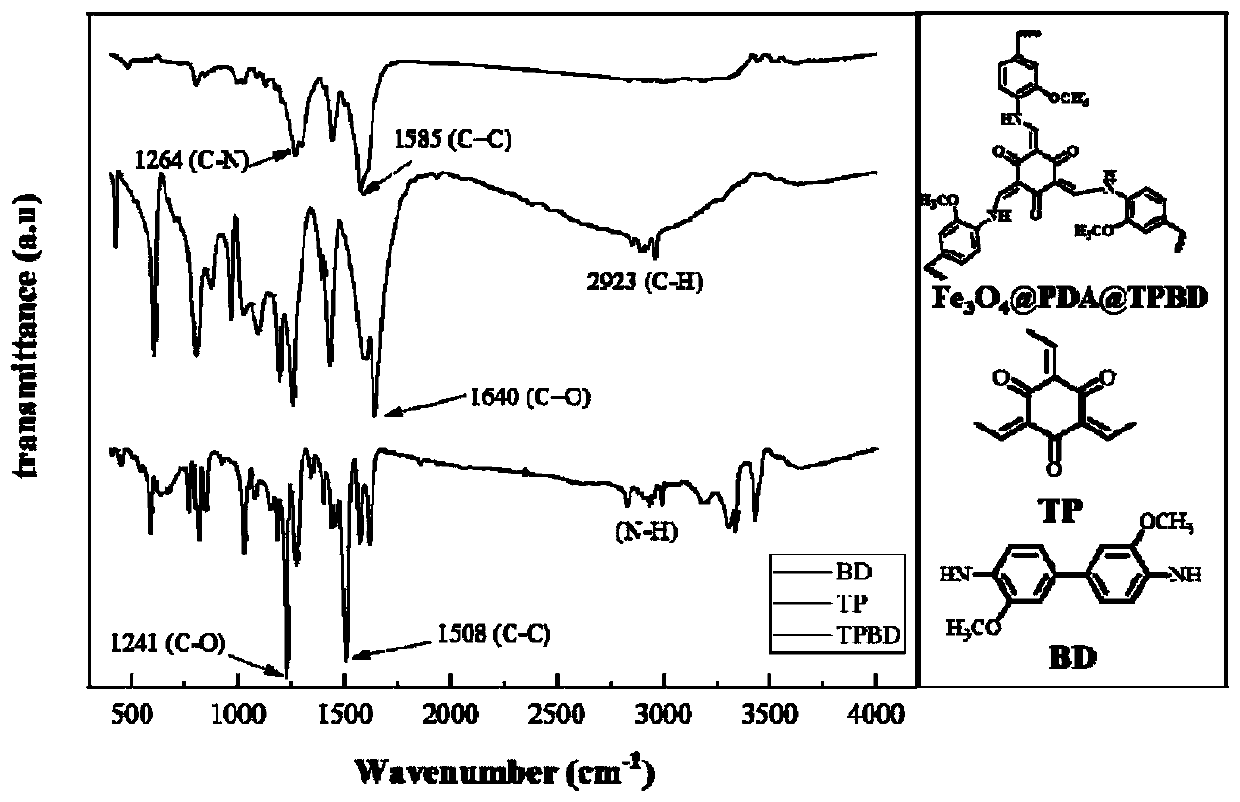

[0034] Another aspect of the present invention provides the preparation method of described composite material, it comprises the following steps:

[0035] (1) Dissolve dopamine hydrochloride, hydrogen peroxide, and copper sulfate in tris buffer solution, then add Fe 3 o 4 Nanoparticles were stirred overnight at room temperature, collected by a magnet, washed, and dried to obtain Fe coated with polydopamine layer. 3 o 4 Particles (also known as Fe 3 o 4 @PDA);

[0036] (2) Fe coated with the polydopamine layer 3 o 4 The particles and amino group-containing alkoxysilane react in a solvent, are collected by a magnet, washed, and dried to obtain a modified polydopamine layer-coated Fe 3 o 4 Particles (also known as modified Fe 3 o 4 @PDA);

[0037] (3) Fe coated with modified polydopamine layer 3 o 4 The particles, 3,3'-dimethoxybenzidine and trialdehyde phloroglucinol are reacted in a solvent at high temperature, and then filtered by a magnet, washed and dried to obt...

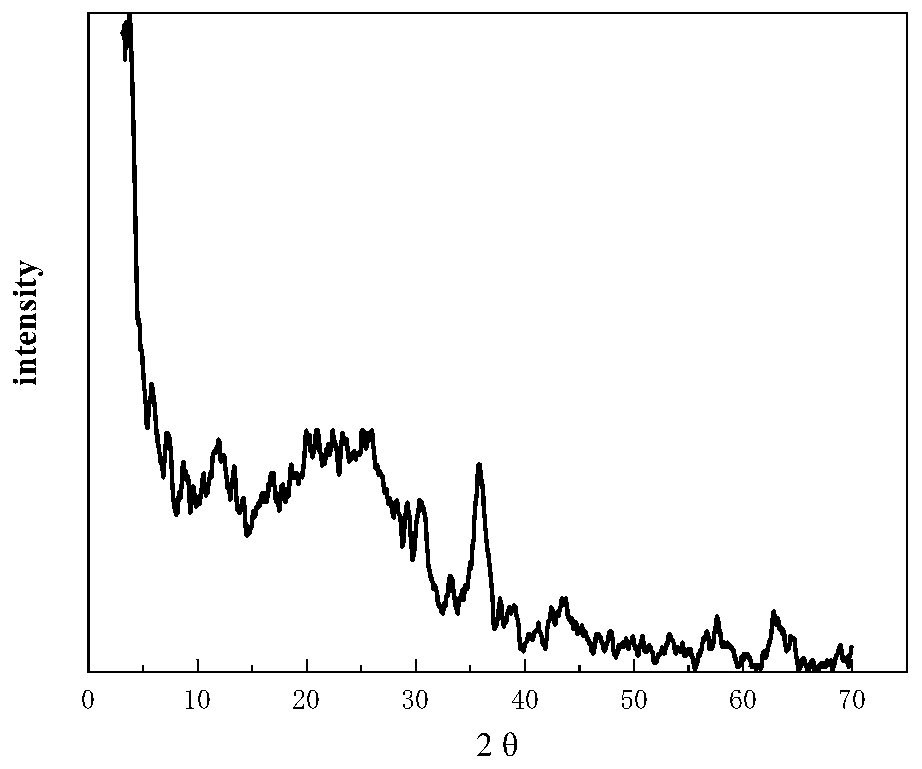

Embodiment 1

[0050] Preparation of composite material of the present invention:

[0051] (1) Fe 3 o 4 Preparation of @PDA: mix dopamine hydrochloride (400mg), hydrogen peroxide (19.6×10 -3 M), copper sulfate (5×10 -3 M), dissolved in 200mL tris buffer solution (200mM, pH 8.5), then added 200mg of Fe 3 o 4 (particle size 200-300nm), stirred overnight at room temperature, then collected by magnet, washed 3 times with ethanol, dried to obtain the product Fe 3 o 4 @PDA.

[0052] (2) Modified Fe 3 o 4 Preparation of @PDA: the resulting Fe 3 o 4 @PDA (200mg) and 3-aminopropyltriethoxysilane (1g) were added to toluene solvent to react; after the reaction was completed, the magnet was collected, washed with ethanol for 3 times, and dried to obtain the product modified Fe 3 o 4 @PDA.

[0053] (3) Fe 3 o 4 Preparation of @PDA@ covalent framework organic composites: the modification of Fe 3 o 4 @PDA (250mg) with 3,3'-dimethoxybenzidine (85mg) and trialdehyde phloroglucinol (65mg) add...

Embodiment 2

[0058] Preparation of composite material of the present invention:

[0059] (1) Fe 3 o 4 Preparation of @PDA: mix dopamine hydrochloride (320mg), hydrogen peroxide (19.6×10 -3 M), copper sulfate (5×10 -3 M), dissolved in 200mL tris buffer solution (200mM, pH 8.5), then added 180mg of Fe 3 o 4 (particle size 200-300nm), stirred overnight at room temperature, then collected by magnet, washed 3 times with ethanol, dried to obtain the product Fe 3 o 4 @PDA.

[0060] (2) Modified Fe 3 o 4 Preparation of @PDA: the resulting Fe 3 o 4 @PDA (180mg) and 3-aminopropyltriethoxysilane (0.8g) were added to toluene solvent to react; after the reaction was completed, the magnet was collected, washed with ethanol 3 times, and dried to obtain the product modified Fe 3 o 4 @PDA.

[0061] (3) Fe 3 o 4 Preparation of @PDA@ covalent framework organic composites: the modification of Fe 3 o 4 @PDA (150mg) with 3,3'-dimethoxybenzidine (45mg) and trialdehyde phloroglucinol (30mg) added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com