Method for catalyzing waste PET polyester methanol alcoholysis by deep eutectic solvent

A technology of deep eutectic solvent and methanol alcoholysis, which is applied in the field of polymer degradation and green catalysis, and can solve the problems of difficult product decolorization, high reaction temperature, and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

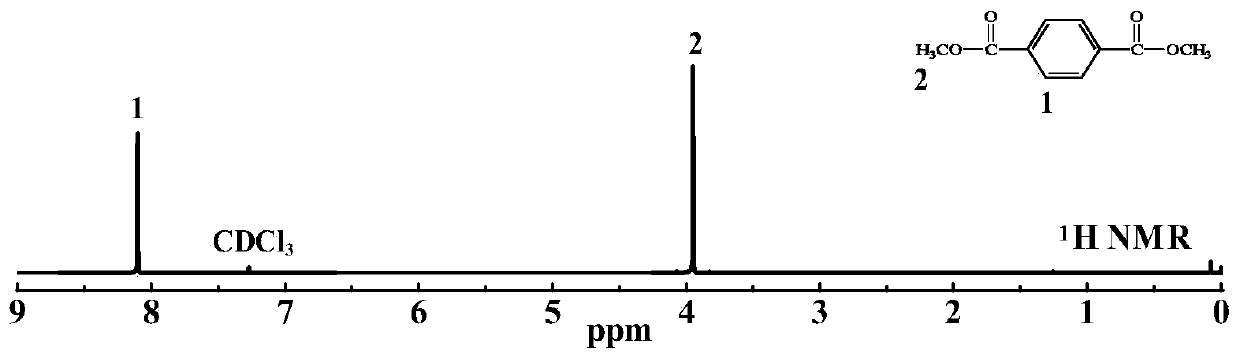

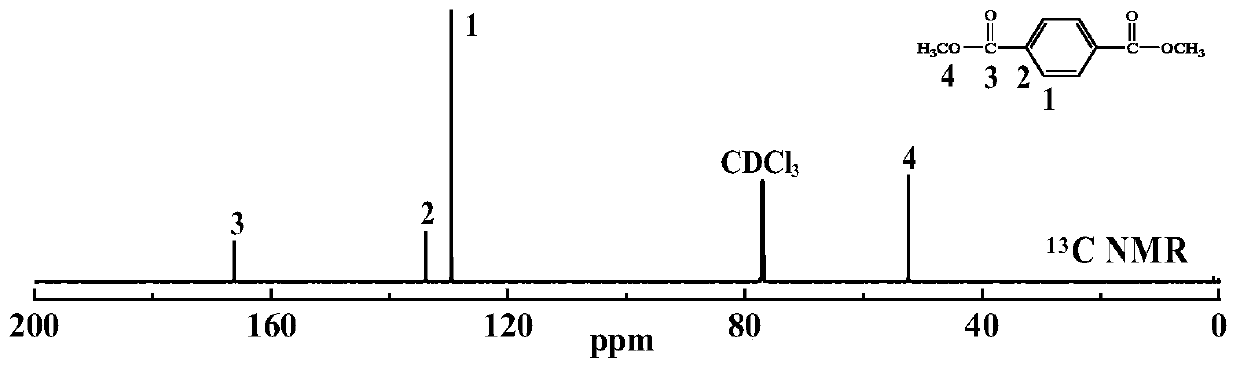

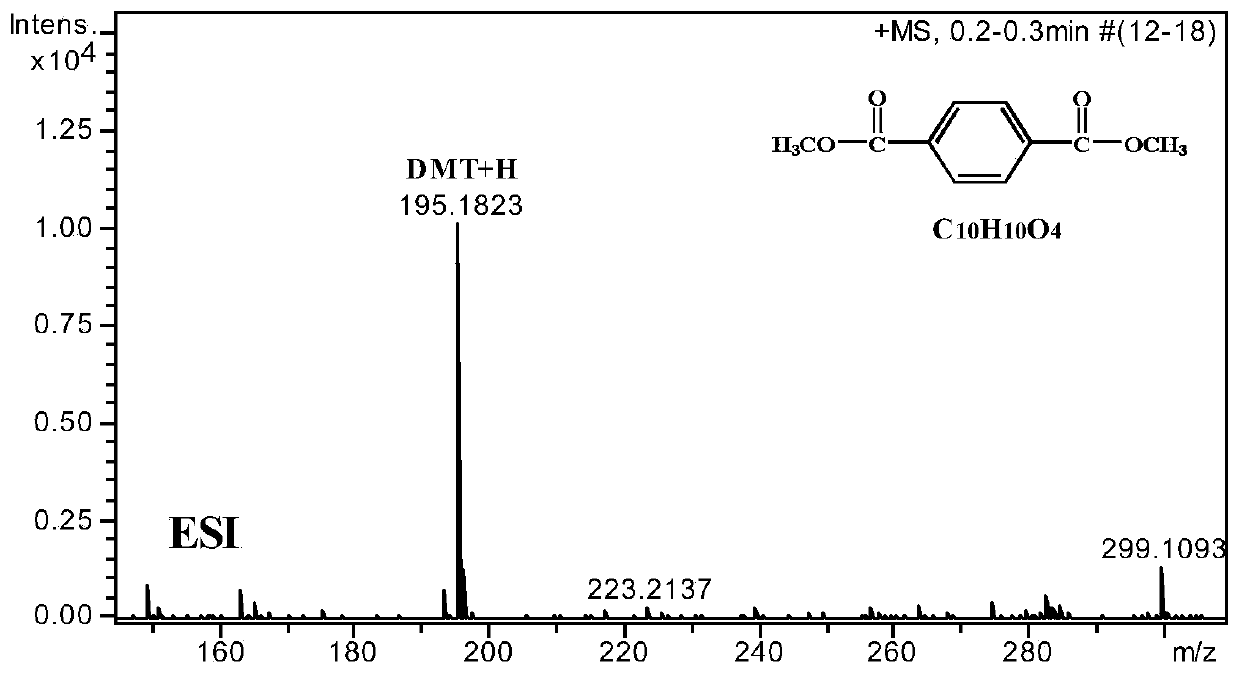

Image

Examples

Embodiment 1-8

[0024] Waste PET bottle flakes and 0.5% of its mass urea / zinc acetate, urea / zinc chloride, urea / zinc sulfate, urea / zinc nitrate, urea / manganese acetate, urea / cobalt acetate, urea / copper acetate, urea / acetic acid Nickel deep eutectic solvent (the molar ratio of urea to metal salt is 4:1) and methanol with a mass ratio of 4:1 were put into the degradation kettle, and the temperature was raised to 170°C, and reacted for 60 minutes. After the reaction finishes, analyze the quality of product DMT and remaining PET, calculate the yield of DMT and the transformation rate of PET. The influence of different catalysts on the methanolysis reaction of waste PET polyester catalyzed by deep eutectic solvents is shown in No. 1-8 in Table 1.

[0025] The effect of different catalysts in Table 1 Examples 1 to 8 on the deep eutectic solvent catalyzed waste PET polyester methanolysis reaction

[0026]

[0027] 2. Effect of catalyst dosage on methanolysis reaction of waste PET polyester catal...

Embodiment 9-12

[0029] Waste PET bottle flakes and its quality 0.1%, 1%, 5%, 10% urea / zinc acetate deep eutectic solvent (the mol ratio of urea and metal salt is 4:1) and its mass ratio is 4:1 Methanol was put into the degradation tank, and after the temperature was raised to 170°C, the reaction was carried out for 60 minutes. After the reaction finishes, analyze the quality of product DMT and remaining PET, calculate the yield of DMT and the transformation rate of PET. The impact of catalyst consumption on the deep eutectic solvent catalyzed waste PET polyester methanolysis reaction is shown in sequence number 9-12 in Table 2.

[0030] Table 2 Examples 9-12 The impact of catalyst dosage on the deep eutectic solvent catalyzed waste PET polyester methanolysis reaction

[0031]

[0032]

[0033] 3. The effect of the amount of methanol on the methanolysis reaction of waste PET polyester catalyzed by deep eutectic solvent

Embodiment 13-17

[0035] Waste PET bottle flakes and its mass 0.5% urea / zinc acetate deep eutectic solvent (the molar ratio of urea and metal salt is 4:1) and its mass ratio is 0.5:1, 1:1, 2:1, 6 :1 or 20:1 methanol is put into the degradation tank, and after heating up to 170°C, react for 60 minutes. After the reaction, analyze the quality of the product DMT and the remaining PET, and calculate the yield of DMT and the conversion rate of PET. The impact of the amount of catalyst on the deep eutectic solvent catalyzed methanolysis of waste PET polyester is shown in the serial number 13-17 in Table 3.

[0036] Table 3 Examples 13-17 The influence of the amount of methanol on the deep eutectic solvent catalyzed waste PET polyester methanolysis reaction

[0037]

[0038] 4. The effect of reaction temperature on methanolysis of waste PET polyester catalyzed by deep eutectic solvent

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com