Automatic chip stacking device

An automatic stacking device and chip technology, which is applied in the directions of transportation and packaging, conveyor objects, and object de-stacking, etc., can solve the problems of poor stacking accuracy and poor stability, and achieve good stability, improve practicability, and facilitate setting. Effects of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

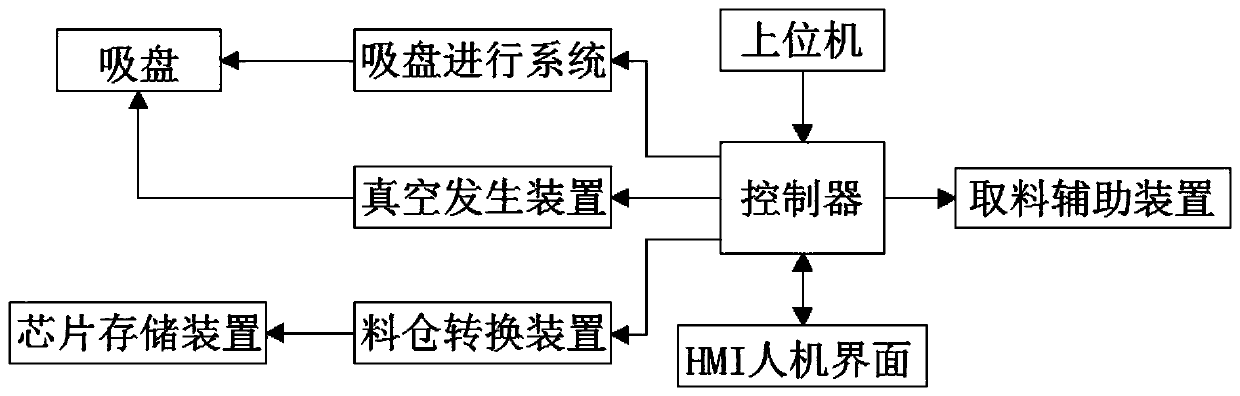

[0016] Such as figure 1 , an automatic stacking device for chips, including a controller, the output end of the controller is bidirectionally electrically connected to an HMI man-machine interface, the HMI man-machine interface includes a support column, and by setting the support column, the HMI man-machine interface is fixed when in use. Stable function, and the bottom of the support column is fixedly connected with a mounting plate, and the surface of the mounting plate is provided with mounting holes. The HMI human-machine interface includes a control panel and a touch screen. The input terminal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com