Furniture antique-finishing process

A technology of furniture and craftsmanship, which is applied in the field of old-fashioned furniture. It can solve the problems of large black and white contrast of furniture, unnatural effects, and long processing time, and achieve the effects of short processing time, accelerated aging process, and extended processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

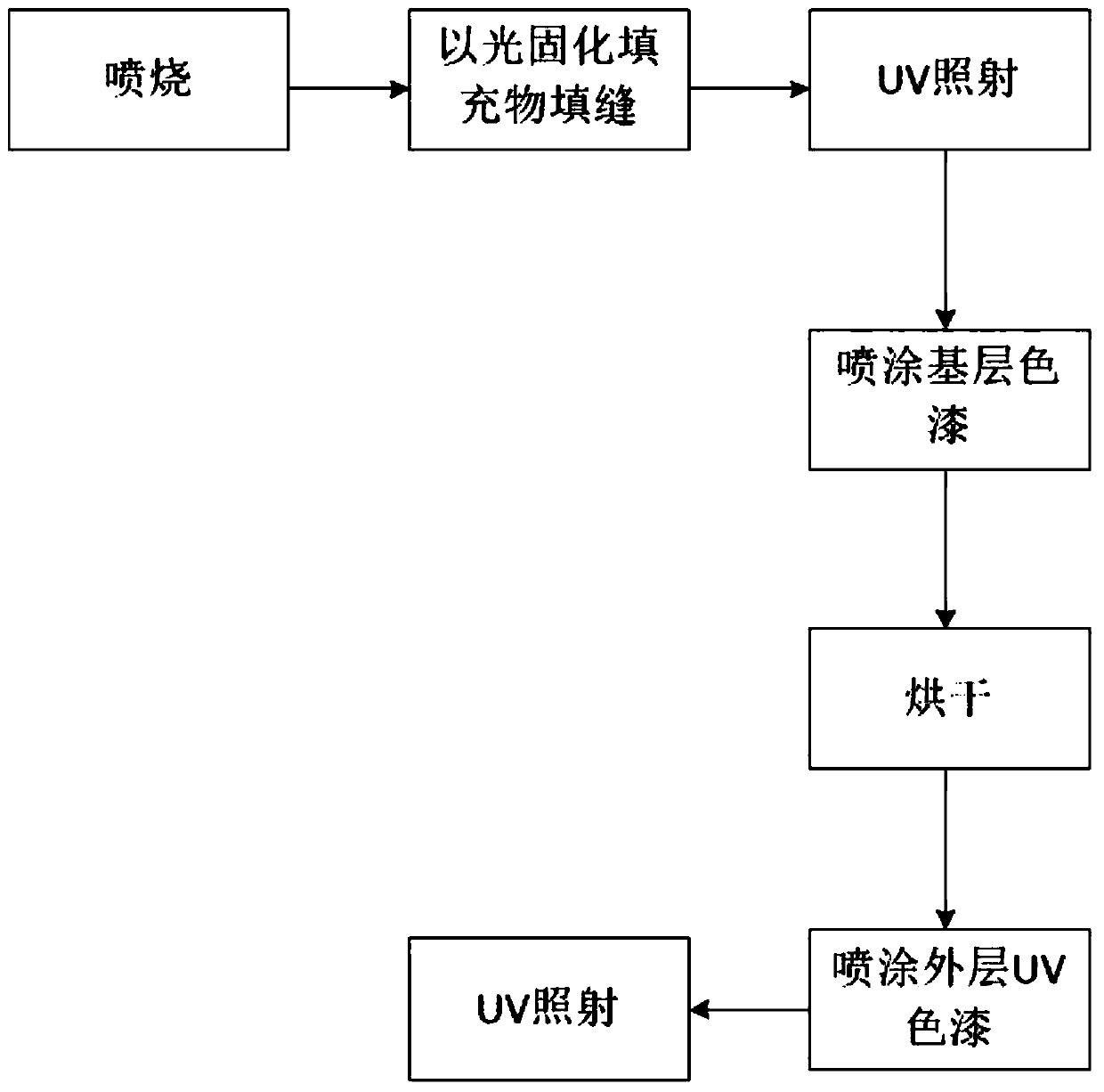

[0041] A process for making old furniture, comprising the following steps:

[0042] S1: Carry out high-temperature spraying and burning on the surface of the assembled furniture, using a high-temperature flame of 300°C at a position 4cm away from the surface of the furniture, and spraying and burning the surface of the furniture for 7 seconds;

[0043] S2: After spraying, fill the cracks on the furniture surface with light-curing fillers;

[0044] S3: UV irradiate the filled furniture at room temperature for 15 minutes;

[0045] S4: Spray the primary color paint on the surface of the furniture by spraying and dry it;

[0046] S5: Spray water on the surface of the cured furniture, and then polish it;

[0047] S6: Spray the outer layer of UV paint on the surface of the furniture by spraying;

[0048] S7: UV irradiation is performed on the furniture for 5 minutes.

[0049] Further, the UV paint used in the S5 includes 50 parts of MPMD resin, 10 parts of diluent, 5 parts of 1-...

Embodiment 2

[0053] A process for making old furniture, comprising the following steps:

[0054] S1: Carry out high-temperature spraying and burning on the surface of the assembled furniture, using a high-temperature flame of 450°C at a position 5cm away from the surface of the furniture, and spraying and burning the surface of the furniture for 4 seconds;

[0055] S2: After spraying, fill the cracks on the furniture surface with light-curing fillers;

[0056] S3: UV irradiate the filled furniture at room temperature for 20 minutes;

[0057]S4: Spray the primary color paint on the surface of the furniture by spraying and dry it;

[0058] S5: Spray water on the surface of the cured furniture, and then polish it;

[0059] S6: Spray the outer layer of UV paint on the surface of the furniture by spraying;

[0060] S7: UV irradiation is performed on the furniture for 7 minutes.

[0061] Preferably, the UV paint used in the S5 includes 60 parts of MPMD resin, 14 parts of diluent, 6 parts of ...

Embodiment 3

[0065] A process for making old furniture, comprising the following steps:

[0066] S1: Carry out high-temperature spraying and burning on the surface of the assembled furniture, using a high-temperature flame of 450°C at a position 5cm away from the surface of the furniture, and spraying and burning the surface of the furniture for 4 seconds;

[0067] S2: After spraying, fill the cracks on the furniture surface with light-curing fillers;

[0068] S3: UV irradiate the filled furniture at room temperature for 20 minutes;

[0069] S4: Spray the primary color paint on the surface of the furniture by spraying and dry it;

[0070] S5: Spray water on the surface of the cured furniture, and then polish it;

[0071] S6: Spray the outer layer of UV paint on the surface of the furniture by spraying;

[0072] S7: UV irradiation is performed on the furniture for 7 minutes.

[0073] Preferably, the UV paint used in the S5 includes 60 parts of polyester acrylate, 14 parts of diluent, 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com