A kind of 3dp preparation method of integral sand mold

An integral, 3DP technology, applied in casting molding equipment, cores, molds, etc., can solve problems such as failure of sand mold preparation of nozzles, blockage of nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

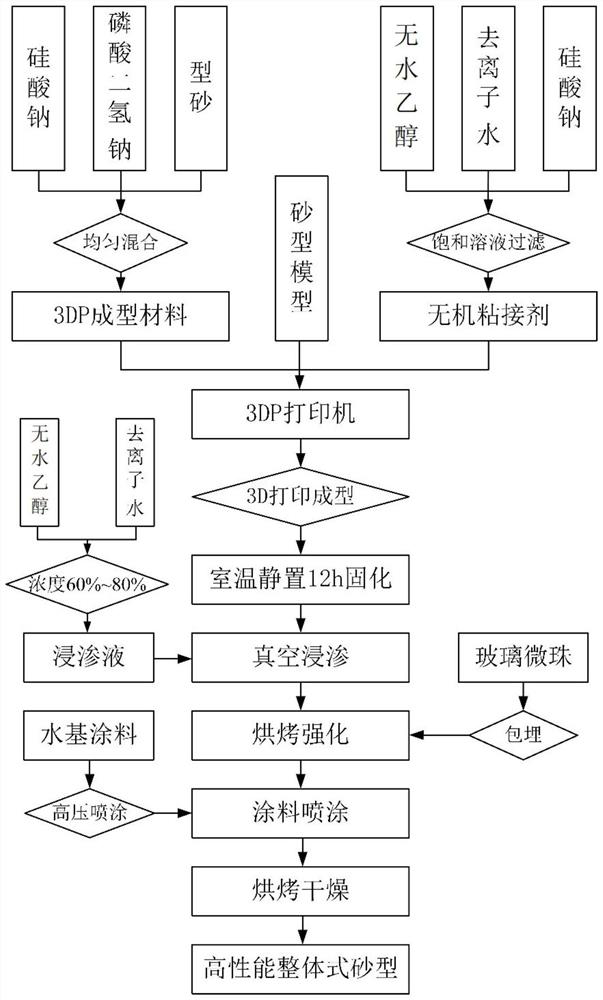

[0029] The 3DP preparation method of the monolithic sand mold of the present invention comprises the following steps:

[0030] S1, mix sodium silicate powder, disodium hydrogen phosphate powder and 3D printing molding sand, fully stir until mixed evenly, to obtain 3DP molding material; wherein the particle size of 3D printing molding sand is 70-140 mesh, sodium silicate powder and dihydrogen phosphate The particle size of the sodium powder is 300-500 mesh, the mass of the sodium silicate powder is 8% to 12% of the mass of the 3D printing sand, and the mass of the disodium hydrogen phosphate powder is 2% to 4% of the mass of the 3D printing sand.

[0031] S2, fully mix absolute ethanol and deionized water in a volume ratio of (1:1)-(1.5:1), dissolve sodium silicate powder in the mixed solution until the solution is saturated, and then stand and filter A clear solution is obtained, and the obtained clear solution is used as an inorganic binder;

[0032] S3, using the above-ment...

Embodiment 1

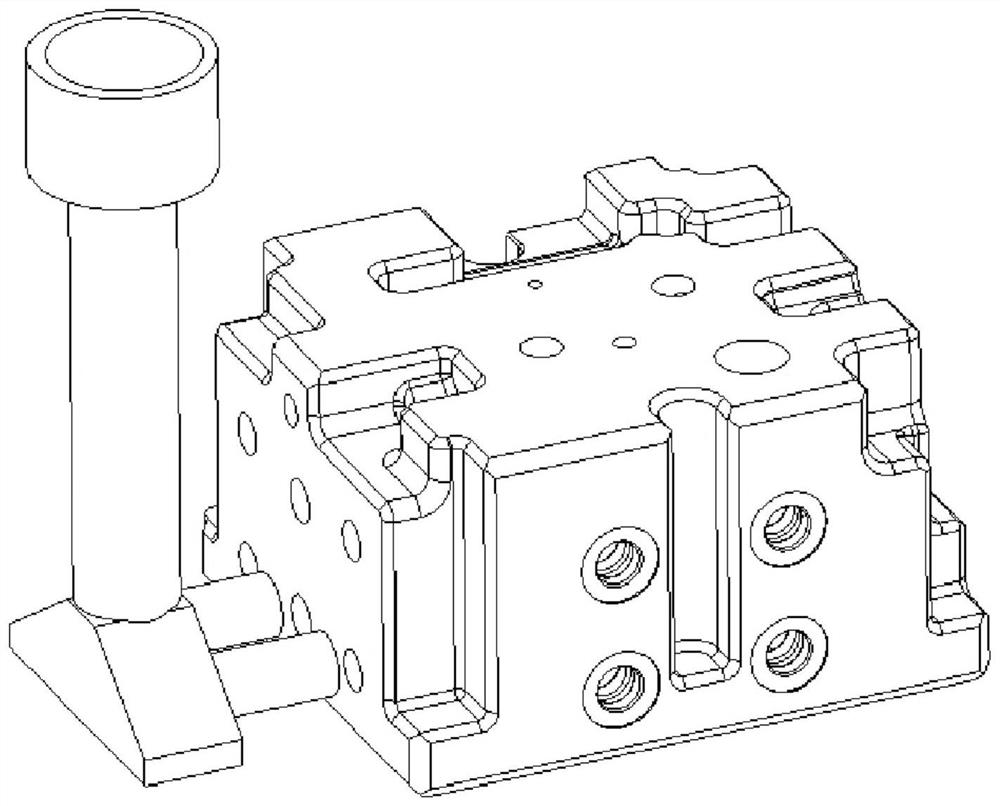

[0051] Using the 3DP preparation method of the integrated sand mold of the present embodiment to manufacture a sand mold of a large-scale integrated high-pressure multi-way valve body with a large number of complex internal flow channels, the following steps are included:

[0052] S1, mix 300-500 mesh sodium silicate powder, 300-500 mesh disodium hydrogen phosphate powder and 70-140 mesh pearl sand, fully stir until the mixture is uniform, to obtain 3DP molding material; wherein, the content of sodium silicate powder is pearl 12% of the sand quality, disodium hydrogen phosphate powder content is 2% of the pearl sand quality;

[0053] S2, fully mix absolute ethanol and deionized water in a volume ratio of 1:1, dissolve sodium silicate powder in the mixed solution until the solution is saturated, then stand and filter to obtain a clear solution, and use the obtained clear solution as an inorganic viscous solution. agent;

[0054] S3, using the above-mentioned 3DP molding materi...

Embodiment 2

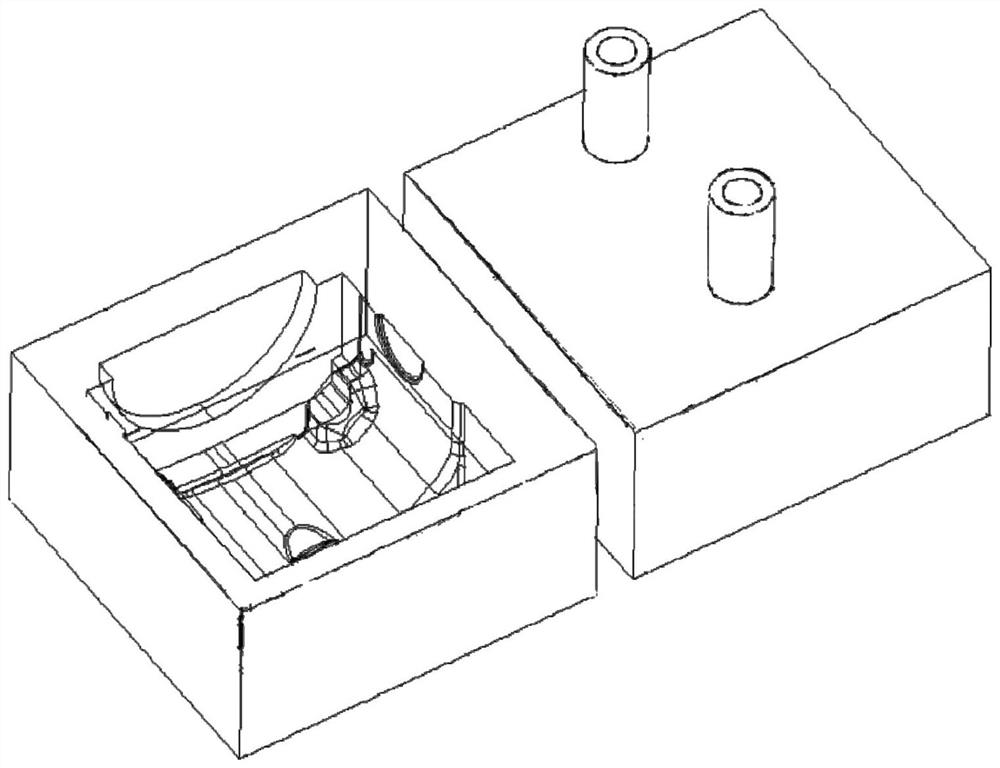

[0062] Utilize the 3DP preparation method of the integral sand mold of the present embodiment to manufacture the sand mold of the hydraulic pump body, including the following steps:

[0063] S1, mix 300-500 mesh sodium silicate powder, 300-500 mesh disodium hydrogen phosphate powder and 70-140 mesh quartz sand, fully stir until the mixture is uniform, to obtain 3DP molding material; wherein, the content of sodium silicate powder is quartz 10% of the sand quality, disodium hydrogen phosphate powder content is 3% of the quartz sand quality;

[0064] S2, fully mix absolute ethanol and deionized water in a volume ratio of 1.5:1, dissolve sodium silicate powder in the mixed solution until the solution is saturated, then stand and filter to obtain a clear solution, and use the obtained clear solution as an inorganic viscous solution. agent;

[0065] S3, using the above-mentioned 3DP molding materials and inorganic adhesives as raw materials for 3D printing molding;

[0066] S4, wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com