Wood grain processing technique for surface of waterproof floor substrate

A wood grain treatment and substrate surface technology, applied in the field of wood grain treatment technology, can solve the problems of no natural wood texture, unrealistic texture, poor simulation effect, etc., to achieve better adhesion effect, improved adhesion effect and quality, and maintain The effect of wood grain texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

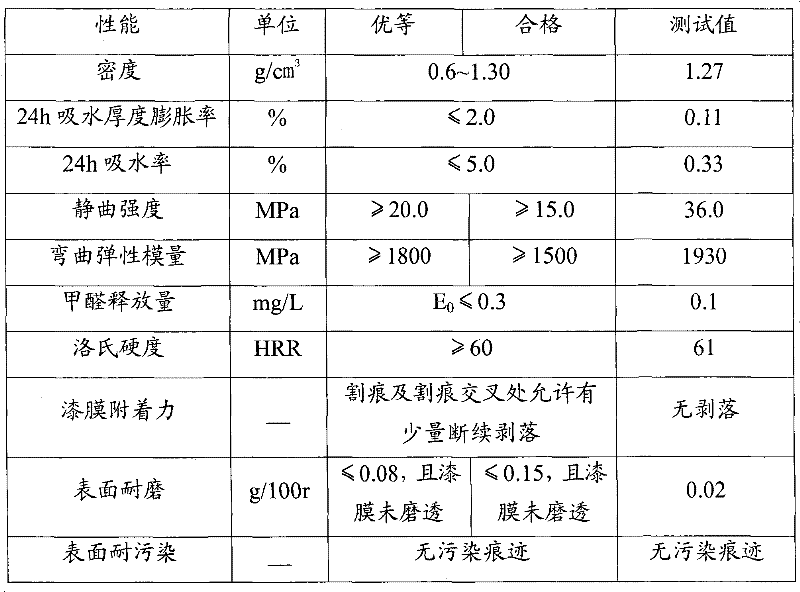

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below.

[0028] A wood grain treatment process for the surface of a waterproof floor base material, which is used for wood grain printing treatment on the base material surface of a carbonized wood-plastic waterproof floor. The surface of the carbonized waterproof wood-plastic floor base material includes two surfaces, the front and the back. The wood grain treatment process includes the following steps:

[0029] a. Perform dust removal treatment on the surface of the carbonized waterproof wood-plastic floor substrate that has been formed;

[0030] b. Use a sander to sand the front of the floor substrate, brush the colored bottom layer, and use a UV curing machine to dry and cure the colored bottom layer;

[0031] c. Smoothen the colored bottom layer and remove dust from the colored bottom layer;

[0032] d. Print simulated wood grain directly on the surface of the floor substrate;

[0033] e. Add a wear-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com