Compressed and laminated wood, production method thereof and compressed and laminated wood

A production method and glulam technology, applied in wood compression, wood processing equipment, other plywood/plywood equipment, etc., can solve the problems of high cost and complicated equipment, achieve increased density, improved strength, and save processing and cutting amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

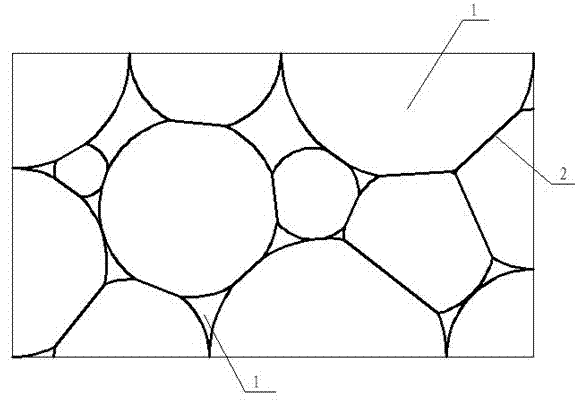

Image

Examples

specific Embodiment 1

[0043] To produce a square compressed glulam with a length of 2 meters and a section of 15 centimeters, the following method steps can be used:

[0044] Step 1. Install an open die with a corresponding section, and taper is provided in the open die.

[0045] Step 2, billet formation: determine the average density of the product to be 0.7 g / cubic centimeter, weigh the corresponding amount, skinless, relatively straight, small-diameter wood with a diameter of about 4 cm, a length of 2 meters, and a moisture content of 20%. It is best to use tree species with similar densities, which have a lot of resin and have poor bonding performance. The raw materials are preferably plantation fast-growing woods, such as eucalyptus, poplar and fir, etc.).

[0046] Step 3, softening with steam above 100°C for 30-60 minutes;

[0047] Step 4. Dip in a relatively low-viscosity phenolic resin with a solid content of 35% and a temperature of 60°C to 80°C for more than a few seconds.

[0048] Step...

specific Embodiment 2

[0055] To produce a compressed glulam bamboo square with a length of 2 meters and a section size of 15 cm x 13 cm, the following steps are involved:

[0056] 1. Install the corresponding section mold;

[0057] 2. Preparation: Cut the 2-meter-long moso bamboo section into 4 pieces, remove the inner and outer sections, flatten, and remove the green bamboo yellow (the thickness does not need to be determined, the thickness can be different within the same piece or between bamboo pieces), and air-dried to a moisture content of 25 %about;

[0058] 3. Blank assembly: the density after compression and integration is 0.8g / cm 3 , Weigh the corresponding amount of bamboo slices: place layers evenly, alternate sizes, and the section size after binding is 2-3cm larger than the size after compression.

[0059] The subsequent steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com