Stranded welding wire for automatic TIG

A welding wire and automatic technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of inability to form a plate, unfavorable production and processing, high energy consumption, etc., to achieve low cost, short production cycle, high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

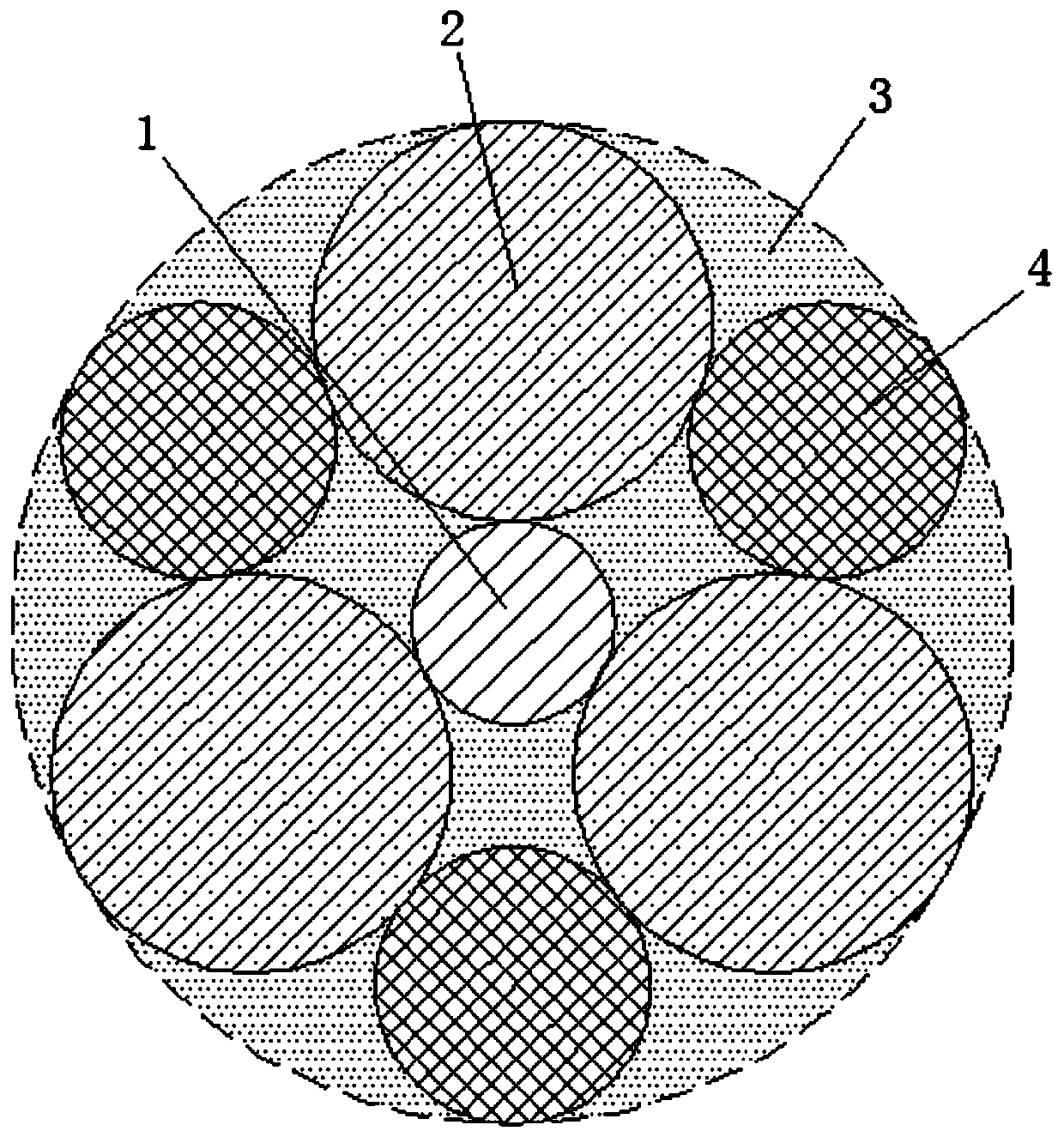

[0021] One SAl1100 intermediate wire 1, three SAl4043 peripheral thick wires 2, and three SAl2319 peripheral stranded wires 4 are selected for twisting, and the intermediate wire 1 is the central peripheral thick wire 2 and the peripheral stranded wire 4 are staggered and twisted. The parameters of the twisting process are: the twist length is 15 times the equivalent diameter of the stranded welding wire, the tension is 15% of the equipment tension rating, the number of rotations is 500r / min, and the chemical composition of the obtained welding wire is Si: 3.2%, Fe: 0.30%, Mg: 0.05%, Zn: 0.07%, Ti: 0.10%, Zr: 0.10%, Mn: 0.10%, V: 0.08%, Cu: 4.1%, and the rest is Al and a very small amount of unavoidable impurities.

Embodiment 2

[0023] One SAl1100 intermediate wire 1, three SAl4043 peripheral thick wires 2, and three SAl2319 peripheral stranded wires 4 are selected for twisting, and the intermediate wire 1 is the central peripheral thick wire 2 and the peripheral stranded wire 4 are staggered and twisted. The parameters of the twisting process are: the twist length is 10 times the equivalent diameter of the stranded welding wire, the tension is 13% of the equipment tension rating, the number of rotations is 450r / min, and the chemical composition of the obtained welding wire is Si: 3.4%, Fe: 0.25%, Mg: 0.04%, Zn: 0.04%, Ti: 0.15%, Zr: 0.20%, Mn: 0.15%, V: 0.12%, Cu: 4.2%, and the rest is Al and a very small amount of unavoidable impurities.

[0024] Example Elongation (%) Tensile strength (MPa) surface cracks and pores 1 6.8 350 none 2 7.1 365 none

[0025] Draw that embodiment 2 is the best solution of the present invention by experimental comparison, therefore is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com