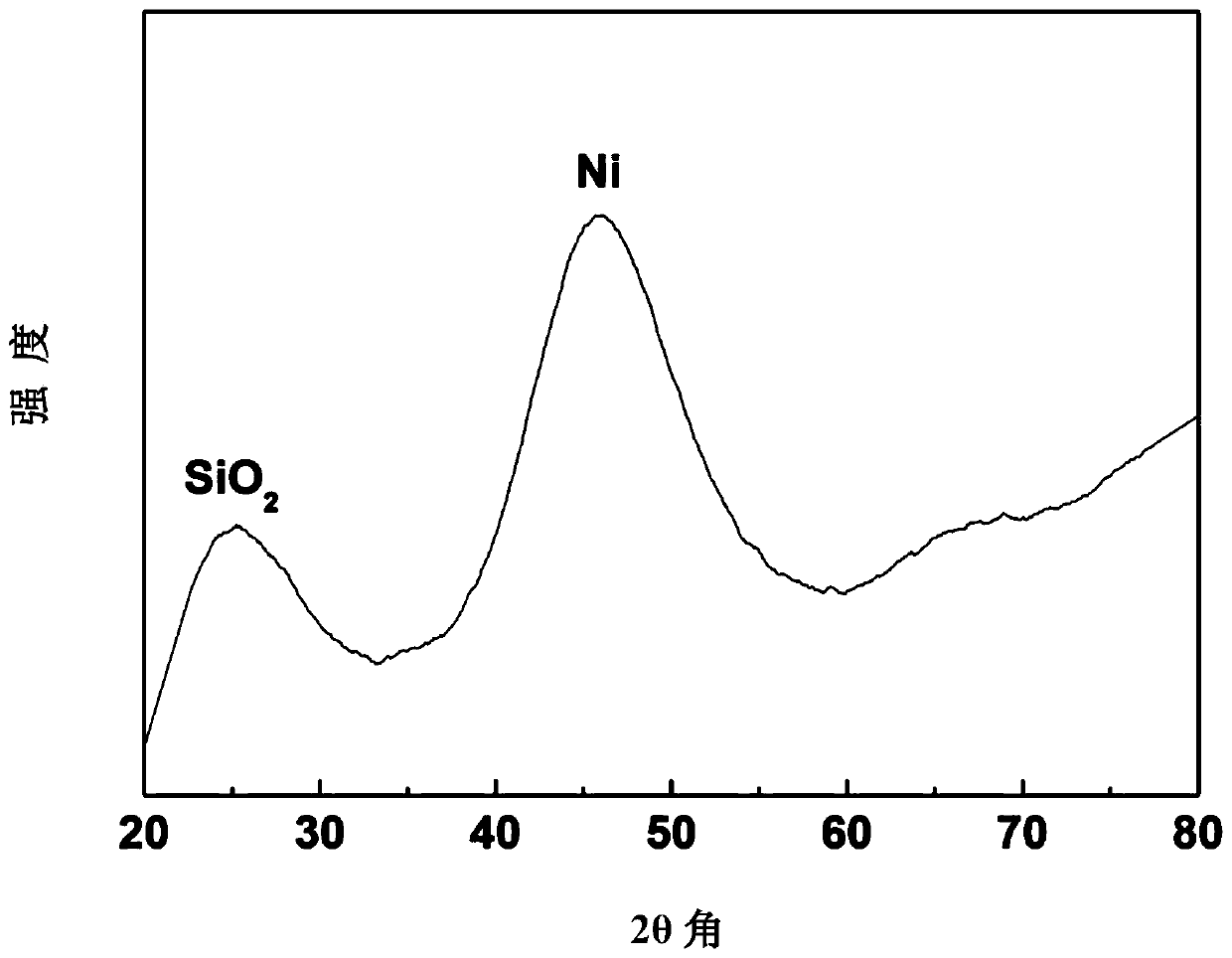

Preparation method of silicon dioxide/nickel core-shell nano-structure material

A nanostructure, silica technology, applied in chemical instruments and methods, microsphere preparation, metal/metal oxide/metal hydroxide catalysts, etc. Expensive and other problems, to avoid the use of precious metals and toxic reagents, controllable performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of solution A: 24.75 mL of deionized water, 16.25 mL of absolute ethanol and 9 mL of 28% concentrated ammonia were mixed under magnetic stirring conditions;

[0049] Preparation of solution B: Mix 4.5mL of tetraethyl orthosilicate and 45.5mL of absolute ethanol under the condition of magnetic stirring;

[0050] Add solution B to solution A quickly and mix, stir at high speed for one minute, then reduce the speed and react at room temperature for two hours. After the reaction was completed, the suspension was centrifuged three times with absolute ethanol, and then dried in a vacuum oven at 80°C to obtain white SiO 2 The microspheres are reserved, denoted as SiO 2 .

[0051] (2) SiO prepared in step (1) 2 The mass ratio of microspheres is 1:100 (SiO 2 : water) ratio dissolved in deionized water, so that SiO 2 The microspheres are evenly dispersed, adjusted to pH=7 with dilute hydrochloric acid, and then according to 40:1 (SiO 2 : PDDA) mass ratio int...

Embodiment 2

[0078] (1) adopt the SiO prepared in embodiment 1 2 Microspheres;

[0079] (2) SiO 2 The mass ratio of microspheres is 1:100 (SiO 2 : water) ratio dissolved in deionized water, so that SiO 2 Disperse evenly, use dilute hydrochloric acid to adjust pH = 7, and then follow the 50:1 (SiO 2 : The mass ratio of PDDA) was added to the PDDA solution, magnetically stirred for 10 min, washed with centrifugal water for 3 times and then dried;

[0080] (3) SiO after processing in step (2) 2 According to the mass ratio of 1:100 (SiO 2 : water) ratio dissolved in deionized water, so that SiO 2 Disperse evenly, use dilute hydrochloric acid to adjust pH = 7, and then follow the 40:1 (SiO 2 : The mass ratio of PSS) is added to the PSS solution, magnetically stirred for 10 min, dried after centrifugal washing for 3 times;

[0081] (4) get SiO after processing in step (3) 2 According to SiO 2 : nickel sulfate hexahydrate: sodium citrate: lactic acid: water=3:20:42:40:8000 (mass ratio) ...

Embodiment 3

[0085] (1) adopt the SiO prepared in embodiment 1 2 Microspheres;

[0086] (2) SiO 2 The mass ratio of microspheres is 1:100 (SiO 2 : the ratio of water) is dissolved in deionized water, and the SiO 2 Disperse evenly, use dilute hydrochloric acid to adjust pH=7, then follow 60:1 (SiO 2: The mass ratio of PDDA) was added to the PDDA solution, magnetically stirred for 10 min, washed with centrifugal water for 3 times and then dried;

[0087] (3) SiO after processing in step (2) 2 According to the mass ratio of 1:100 (SiO 2 : water) ratio dissolved in deionized water, so that SiO 2 Disperse evenly, use dilute hydrochloric acid to adjust pH = 7, and then follow the 50:1 (SiO 2 : The mass ratio of PSS) is added to the PSS solution, magnetically stirred for 10 min, dried after centrifugal washing for 3 times;

[0088] (4) get SiO after processing in step (3) 2 According to SiO 2 : nickel sulfate hexahydrate: sodium citrate: lactic acid: water=7:85:8:20:4000 (mass ratio) is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com