Vertical structure LED chip and preparation method thereof

A LED chip and vertical structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high local heating, uneven electrical distribution, etc., and achieve the effects of prolonging service life, improving luminous intensity, and high luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

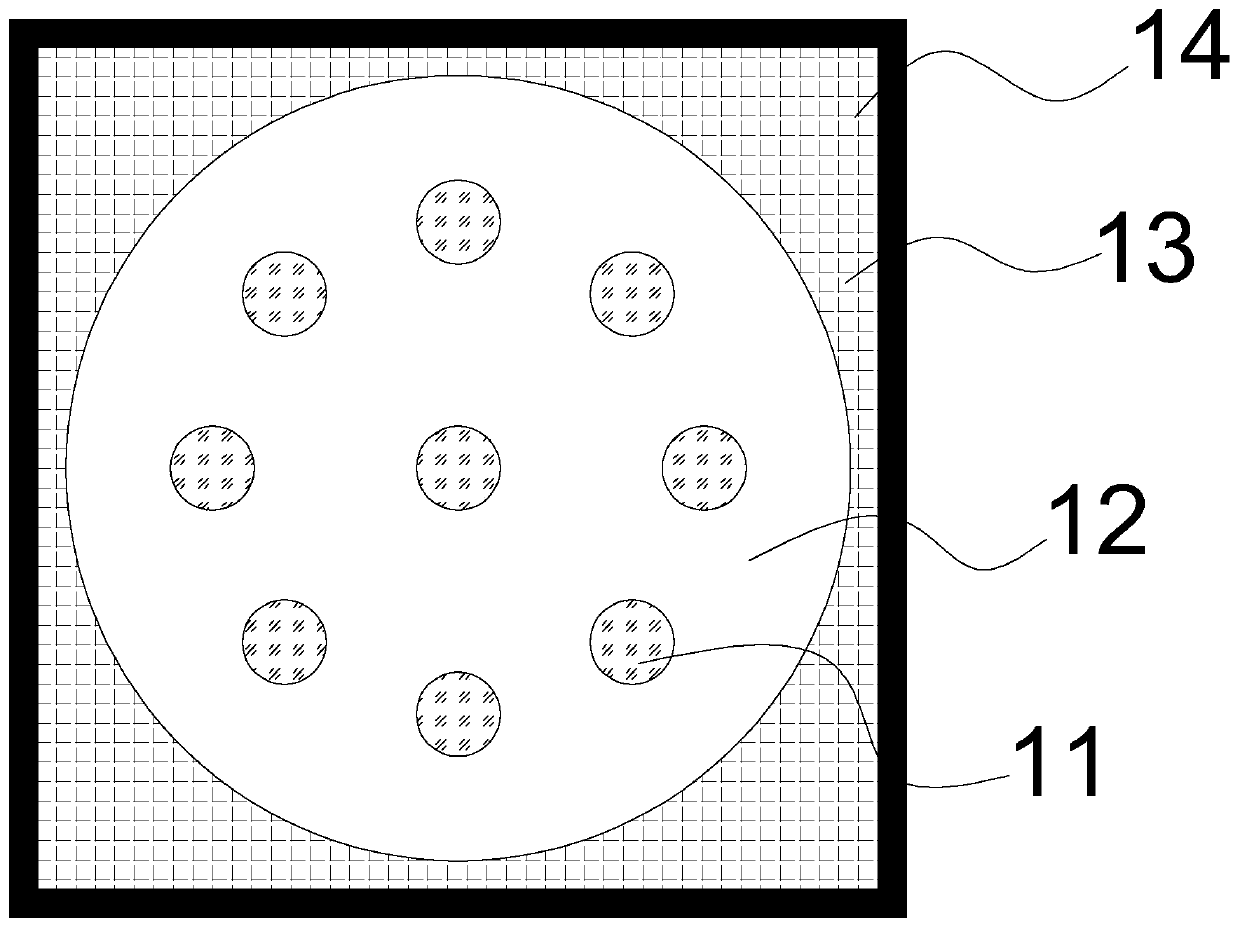

[0047] A kind of vertical structure LED chip, its longitudinal section structure is as follows figure 1 As shown, it includes a base layer and a circular light-emitting surface 12 arranged on the base layer and a P electrode 13 arranged on the outer edge of the circular light-emitting surface 12. The circular light-emitting surface 12 is coaxial with the P electrode 13; An insulating wall 14 is provided on the outside; a plurality of N electrode columns 11 are arranged inside the circular light emitting surface 12, and the plurality of N electrode columns 11 are distributed on the circular light emitting surface 12 in the form of a ring or a polygon, centrally or axisymmetrically. Among them, the bottom end of the N electrode column 11 is electrically connected to the base layer, and the top end is electrically connected to the circular light emitting surface 12 .

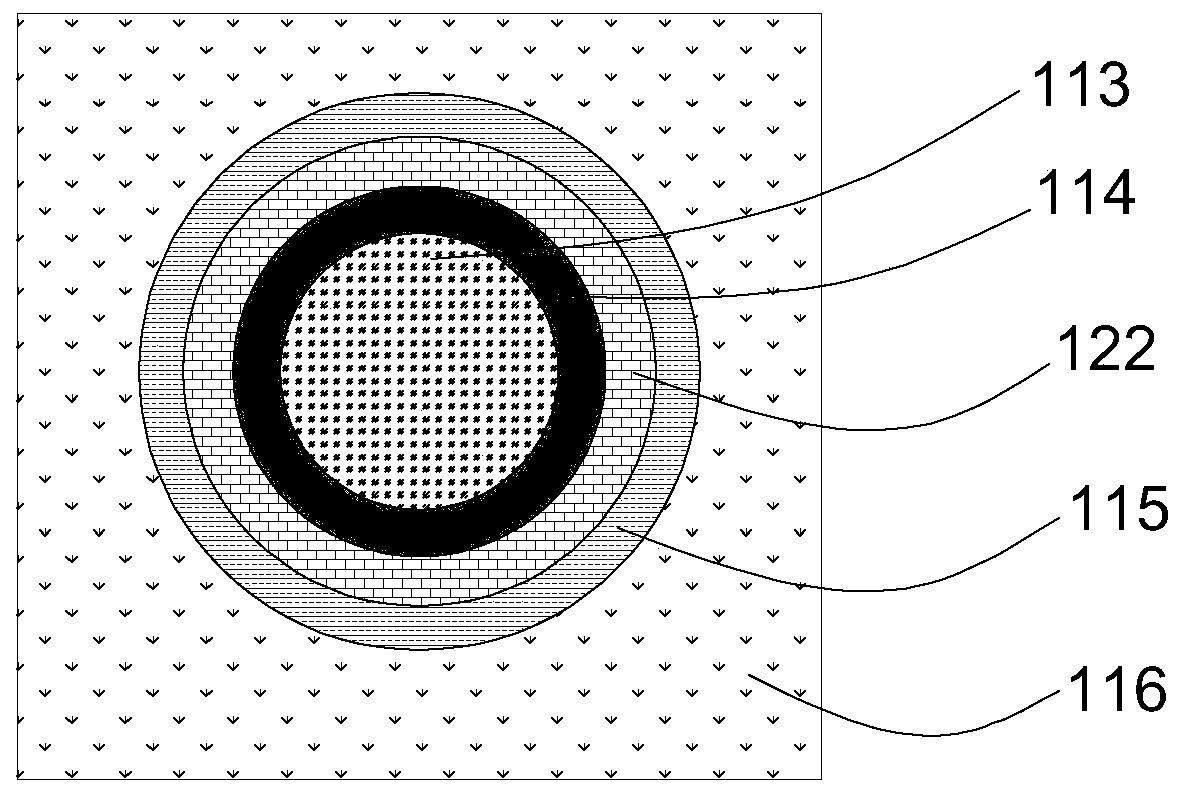

[0048] Such as figure 2 As shown, wherein the circular light-emitting surface 12 includes LED epitaxial layers...

Embodiment 2

[0051] A vertical structure LED chip, such as Figure 1-Figure 3 As shown, it includes a base layer, a circular light-emitting surface 12 arranged on the base layer, and a P electrode 13 arranged on the outer edge of the circular light-emitting surface 12. The circular light-emitting surface 12 is concentric with the P electrode 13; the peripheral device of the P electrode 13 There is an insulating wall 14; the circular light-emitting surface 12 is a 35mil×35mil LED chip, and a plurality of 9 electrode columns are arranged inside, one of the plurality of N electrode columns 11 is located at the center point, and the other 8 are arranged in a circular array around the center point Distributed in the circular light emitting surface 12 , the bottom end of the N electrode column 11 is electrically connected to the base layer, and the top end is electrically connected to the circular light emitting surface 12 .

[0052] Among them, the circular light-emitting surface 12 includes an...

Embodiment 3

[0075] A vertical structure LED chip, such as Figure 4 As shown, it includes a base layer, a circular light-emitting surface 12 arranged on the base layer, and a P electrode 13 arranged on the outer edge of the circular light-emitting surface 12. The circular light-emitting surface 12 is concentric with the P electrode 13; the peripheral device of the P electrode 13 There is an insulating wall 14; the circular light-emitting surface 12 is a 35mil×35mil LED chip, and 14 N electrode columns 11 are arranged inside, and the 14 N electrode columns 11 are adjacent to each other in a diamond shape, and the circular light-emitting surface 12 is symmetrically distributed in the center In the circular light emitting surface 12 , the bottom end of the N electrode post 11 is electrically connected to the base layer, and the top end is electrically connected to the circular light emitting surface 12 .

[0076] Among them, the circular light-emitting surface 12 includes an LED epitaxial la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com