Flexible fabric pressure and strain composite sensor

A composite sensor and flexible fabric technology, which is applied in the direction of instruments, force measurement, electric/magnetic solid deformation measurement, etc., can solve the problems of easy falling off of electrode leads, cumbersome preparation process, and difficult large-scale processing, so as to avoid delamination and peeling, Good air permeability and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

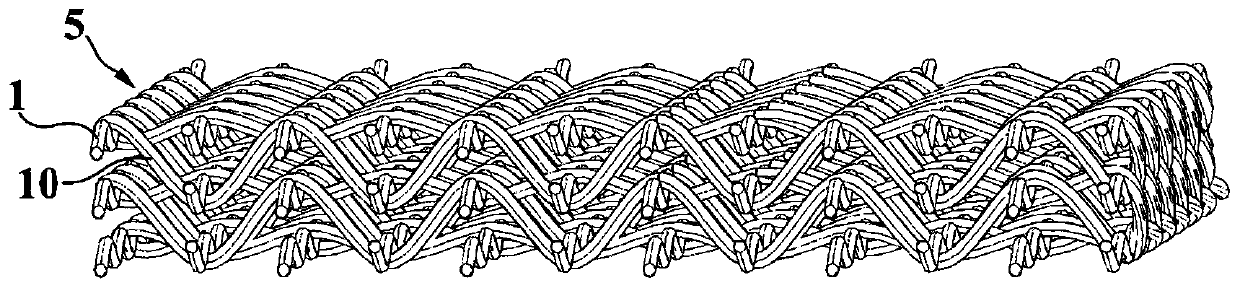

[0026] The metal plated metal material of the metal-plated conductive yarn in the present invention is conductive metal materials such as silver, copper, nickel, aluminum, zinc, gold, and the silver-plated conductive material is selected in this embodiment. Such as figure 1 As shown, a flexible fabric pressure and strain composite sensor of the present invention is a capacitive flexible sensor including an upper conductive layer fabric 12, an insulating layer fabric 7, a lower conductive layer fabric 13, and a first connection at both ends that are stacked sequentially from top to bottom. part 5 and the second connecting part 6. Wherein, the upper conductive layer fabric 12, the insulating layer fabric 7 and the lower conductive layer fabric 13 constitute the sensing area 2 of the flexible fabric pressure and strain composite sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com