A steel skeleton foam concrete composite structure unit house

A technology of foam concrete and composite structure, which is applied in the direction of building structure and construction, and can solve the problems of prefabricated houses that cannot be built, large disassembly and assembly losses, and difficult to reuse, so as to achieve rich use functions, high bearing capacity, and easy scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

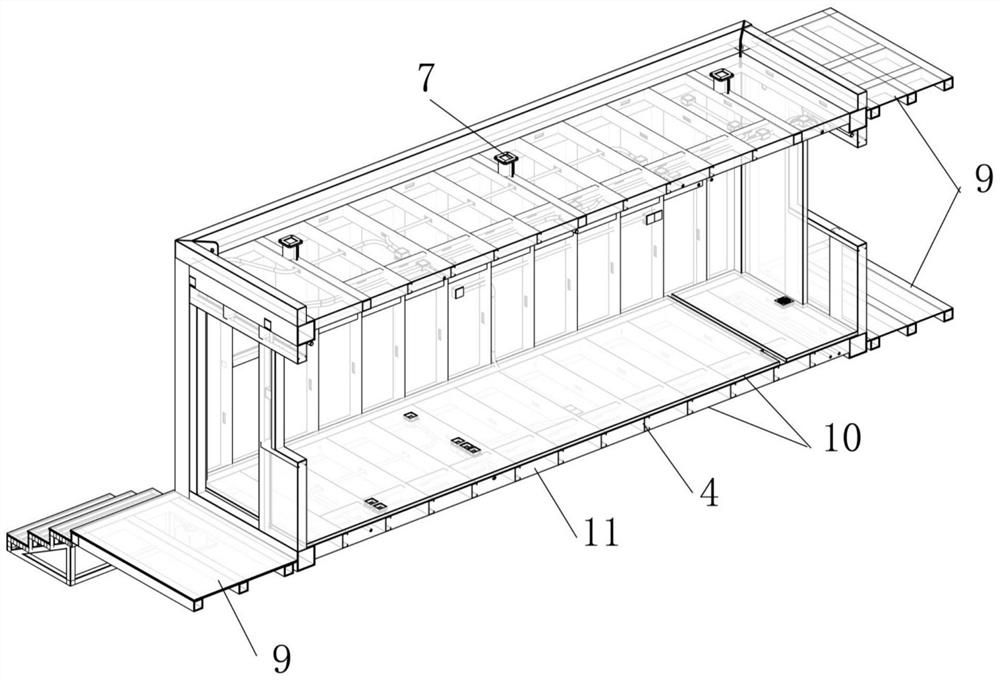

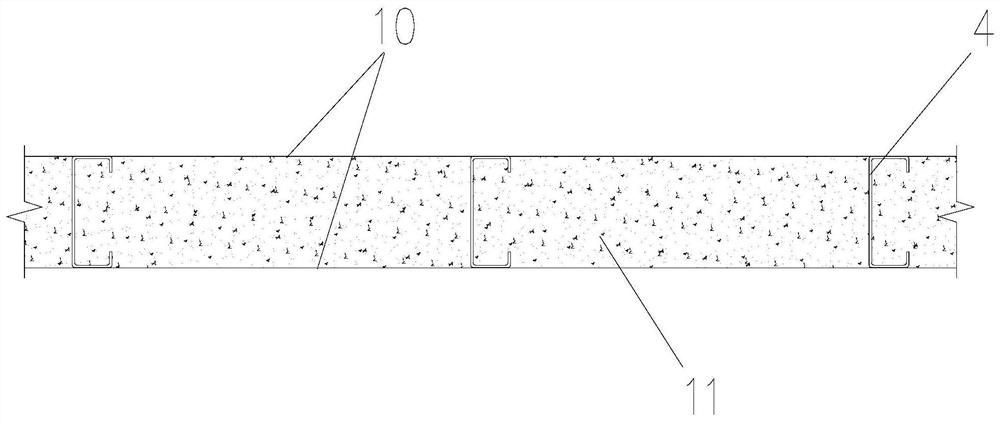

[0042] The steel frame foam concrete composite structure unit house of the present embodiment, such as Figure 1-3 As shown, it includes a steel frame structure of a mobile unit house, a panel 10 and a foam concrete 11.

[0043] Such as Figure 4 with Figure 5 As shown, the steel skeleton structure of the mobile unit house consists of 4 equal-length X-axis square tubes 1, 4 equal-length Y-axis square tubes 2, and 4 equal-length Z-axis square tubes 3 welded through 8 coordinate nodes The formed right-angled cuboid three-dimensional frame, wherein, the square pipe is a square steel pipe, and any four square pipes are connected in turn to form a right-angled quadrilateral frame. It is formed by criss-cross welding of C-shaped steel, and the bottom plate of C-shaped steel is provided with flow holes for the flow of foamed concrete. The keel frame 4 at one end along the X-axis direction is provided with a door opening 41 and a window opening 42 . The lower ends of the four Z-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com