Bovine bone peptide and its preparation process

A preparation process, the technology of bovine bone, which is applied in the field of nutritional products, can solve the problems of high protein loss rate and achieve the effect of high peptide content, high decolorization rate and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

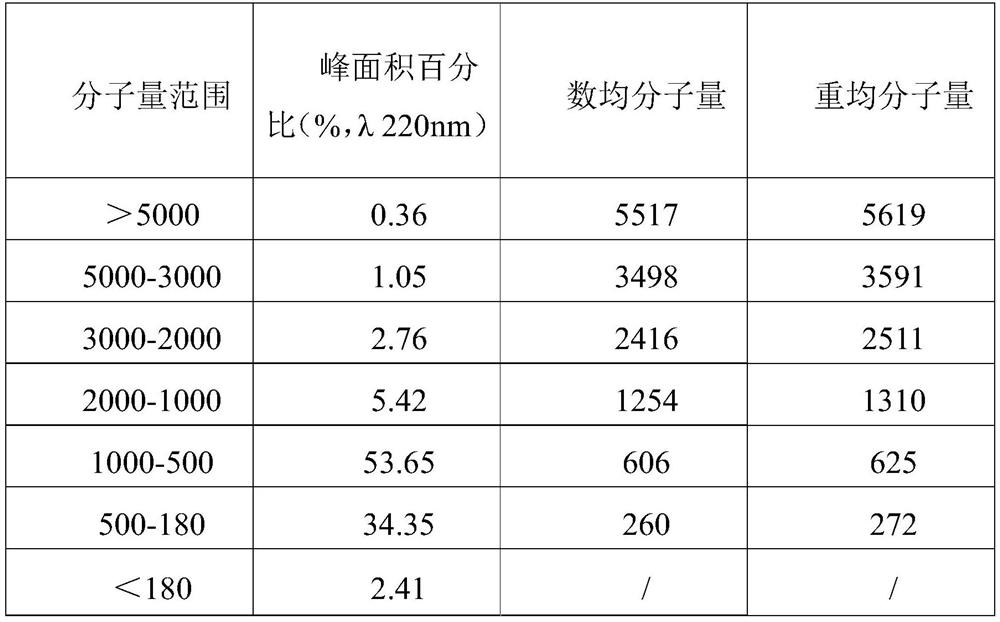

Image

Examples

Embodiment 1

[0033] A kind of bovine bone peptide and preparation technology thereof, comprises the following steps:

[0034] S1 beef bone cleaning: soak fresh beef bones in cold water, wash and remove blood stains;

[0035] S2 Freezing: After washing, the bovine bones are frozen at -15°C for 24 hours, and then cut into 5 cm grains;

[0036] S3 Cooking to degrease, pulverize and dry: Cook the frozen and chopped beef bones at 0.3kPa and 110°C for 80 minutes at high temperature, centrifuge and degrease to obtain beef bones, rinse the beef bones with water, dry at low temperature, crush and sieve to obtain bone meal;

[0037] S4 Enzymolysis: Mix bone powder and water at a mass ratio of 1:30 to obtain bone powder liquid, adjust the pH to 6.0, then add compound enzyme and enzymatic hydrolysis aid, the amount of compound enzyme added is 600U / mL bone powder liquid, and enzymatically After hydrolysis for 6 hours, the enzyme was deactivated at high temperature after the enzymolysis, and the supern...

Embodiment 2

[0047] A kind of bovine bone peptide and preparation technology thereof, comprises the following steps:

[0048] S1 beef bone cleaning: soak fresh beef bones in cold water, wash and remove blood stains;

[0049] S2 Freezing: After washing, the bovine bones are frozen at -15°C for 24 hours, and then cut into 5 cm grains;

[0050] S3 Cooking to degrease, pulverize and dry: Cook the frozen and chopped beef bones at 0.3kPa and 110°C for 80 minutes at high temperature, centrifuge and degrease to obtain beef bones, rinse the beef bones with water, dry at low temperature, crush and sieve to obtain bone meal;

[0051] S4 Enzymolysis: Mix bone powder and water at a mass ratio of 1:30 to obtain bone powder liquid, adjust the pH to 6.0, then add compound enzyme and enzymatic hydrolysis aid, the amount of compound enzyme added is 600U / mL bone powder liquid, and enzymatically After hydrolysis for 6 hours, the enzyme was deactivated at high temperature after the enzymolysis, and the supern...

Embodiment 3

[0060] A kind of bovine bone peptide and preparation technology thereof, comprises the following steps:

[0061] S1 beef bone cleaning: soak fresh beef bones in cold water, wash and remove blood stains;

[0062] S2 Freezing: After washing, the bovine bones are frozen at -15°C for 24 hours, and then cut into 5 cm grains;

[0063] S3 Cooking to degrease, pulverize and dry: Cook the frozen and chopped beef bones at 0.3kPa and 110°C for 80 minutes at high temperature, centrifuge and degrease to obtain beef bones, rinse the beef bones with water, dry at low temperature, crush and sieve to obtain bone meal;

[0064] S4 Enzymolysis: Mix bone powder and water at a mass ratio of 1:30 to obtain bone powder liquid, adjust the pH to 6.0, then add compound enzyme and enzymatic hydrolysis aid, the amount of compound enzyme added is 600U / mL bone powder liquid, and enzymatically After hydrolysis for 6 hours, the enzyme was deactivated at high temperature after the enzymolysis, and the supern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com