Flexible material composition, flexible material and its preparation method, plugging agent and its application

A flexible material and plugging agent technology, applied in the field of drilling fluid, can solve the problems of weak pressure bearing capacity of the plugging layer, inability to automatically remove plugging, weak self-adaptive ability, etc., and achieve high plugging success rate and low impact on drilling fluid performance Small, Adaptive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0079] (1) Prepare the composition according to the following components and contents:

[0080] Acrylamide, 100 parts by weight;

[0081] Dimethyl diallyl ammonium chloride, 30 parts by weight;

[0082] Ammonium persulfate, 3 parts by weight;

[0083] N, N'-methylenebisacrylamide, 10 parts by weight;

[0084]Water (deionized water), 260 parts by weight.

[0085] (2) Preparation of flexible materials:

[0086] The composition prepared in step (1) is added to the container, and each component in the composition is dissolved in water to obtain a mixed solution. First, at room temperature (20° C.), nitrogen protection was passed through the mixed solution, and stirred for 25 min to obtain a first mixture. Then, the temperature of the first mixture was adjusted to 55° C., nitrogen flow and stirring were stopped, and the first mixture was allowed to stand at this temperature for 4 hours to obtain a gel-like second mixture. Finally, the second mixture is dried until the moistur...

Embodiment A2-A5

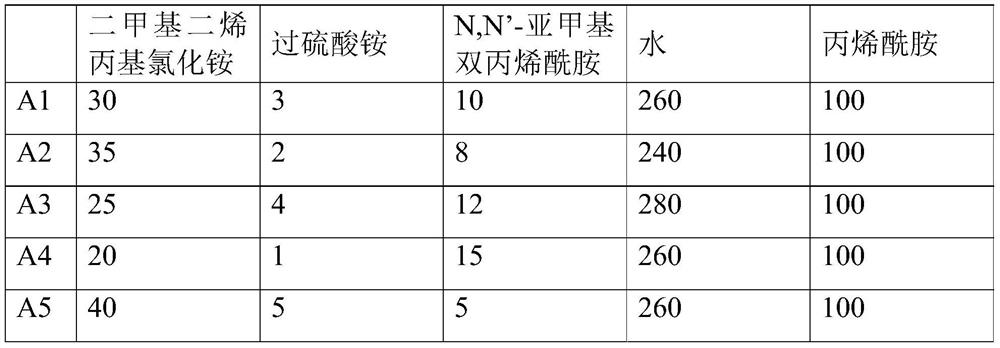

[0088] Carry out according to the method of embodiment A1, the difference is that embodiment A2-A5 changes the content of each component in the composition respectively, specifically as shown in Table 1, and the products obtained are recorded as A2-A5 respectively.

[0089] Table 1

[0090]

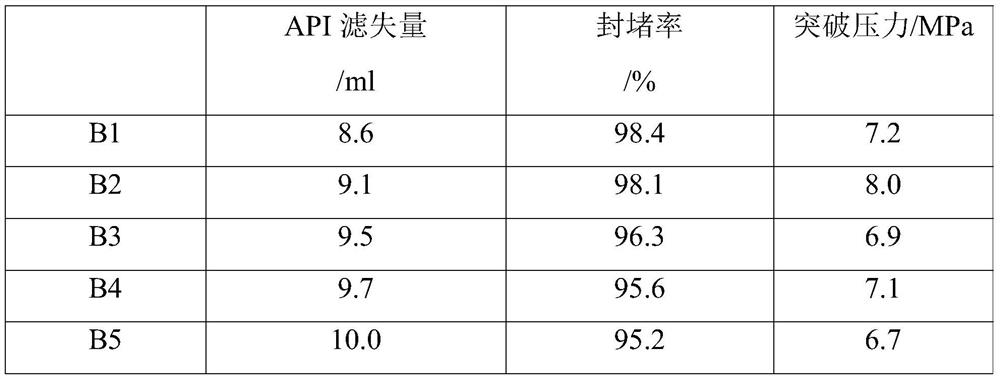

Embodiment B1

[0103] (1) Prepare the composition according to the following components and contents:

[0104] Flexible material: 100 parts by weight; A1;

[0105] Oil-soluble resin: 65 parts by weight; purchased from Shandong Deshunyuan Petroleum Technology Co., Ltd., brand EP-1;

[0106] Fiber: 50 parts by weight; Polypropylene fiber (Zibo Longen Fiber Co., Ltd., TP-2);

[0107] Asphalt: 70 parts by weight; purchased from Shandong Deshunyuan Petroleum Technology Co., Ltd., brand FF-Ⅱ;

[0108] Rigid material: 85 parts by weight; calcium carbonate with a particle size of 100 mesh to 200 mesh.

[0109] (2) Put the flexible material, oil-soluble resin and asphalt prepared in step (1) into the mixer, and mix for 15 minutes; then continue to add fibers and rigid materials, and mix for 15 minutes. The final lost circulation agent is obtained, denoted as B1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com