Inorganic texture material and application of inorganic texture material in decoration

An inorganic coating and texture technology, applied in construction, building structure, covering/lining, etc., can solve the problems of poor control of water addition rate, high production process requirements, and difficult production, to inhibit the growth and spread of mold, beautify Building and environment, the effect of favorable environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of Inorganic Texture Decorative Materials

[0038] Option One:

[0039] This example includes the inorganic texture materials in the present invention: 30 parts of 425# white cement, 15 parts of 0.1-0.2mm textured white sand, 30 parts of 0.2-0.4mm textured white sand, 15 parts of 0.4-1.0mm textured white sand, dispersible latex powder 4 parts, 2 parts thickener, 2 parts water repellent, 2 parts wood fiber.

[0040] Option II:

[0041] This example includes the inorganic texture materials in the present invention: 28 parts of 425# white cement, 18 parts of 0.1-0.2mm textured white sand, 30 parts of 0.2-0.4mm textured white sand, 15 parts of 0.4-1.0mm textured white sand, dispersible latex powder 3 parts, 2 parts thickener, 2.5 parts water repellent, 1.5 parts wood fiber.

[0042] third solution:

[0043] This embodiment includes the inorganic texture materials in the present invention: 20 parts of 425# white cement, 10 parts of 0.1-0.2mm texture...

Embodiment 2

[0052] Example 2 Preparation and implementation process of inorganic texture decoration system

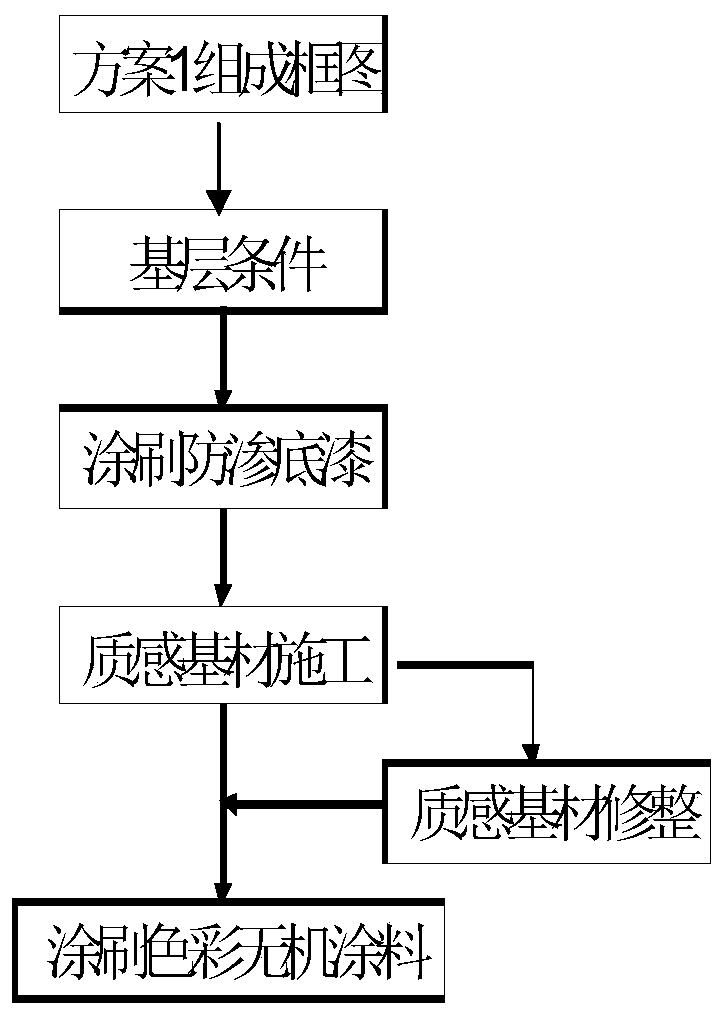

[0053] Scheme 1: Scheme with primer ( figure 1 )

[0054] 1. Wall base conditions and quality standards:

[0055] Base conditions: The base of the wall is a mineral base, including the base of thermal insulation plastering, cement plastering, concrete base and other mineral bases.

[0056] Quality standard: The flatness requirements meet the requirements of fine plastering standards and decorative effect requirements; the base layer has good strength, no sand, no hollow, dry moisture content of the base layer <10%, no pan-alkali PH <10.

[0057] 2. Brush the base layer anti-seepage interface primer once, and apply it evenly.

[0058] 3. After the primer is dried, spray or smear the polymer texture substrate, which requires a natural and beautiful texture and uniform particle distribution.

[0059] 4. Detail treatment of textured substrate: After the substrate is dried, repair t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com