A kind of concrete with low heat of hydration and high strength volume and preparation method thereof

A mass concrete, low hydration heat technology, applied in the field of high-performance building materials, can solve the problems of low hydration heat, unfavorable concrete pumping construction, concrete bleeding, etc., to reduce bleeding problems, enhance later strength and Anti-sulfate corrosion ability, the effect of enhancing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

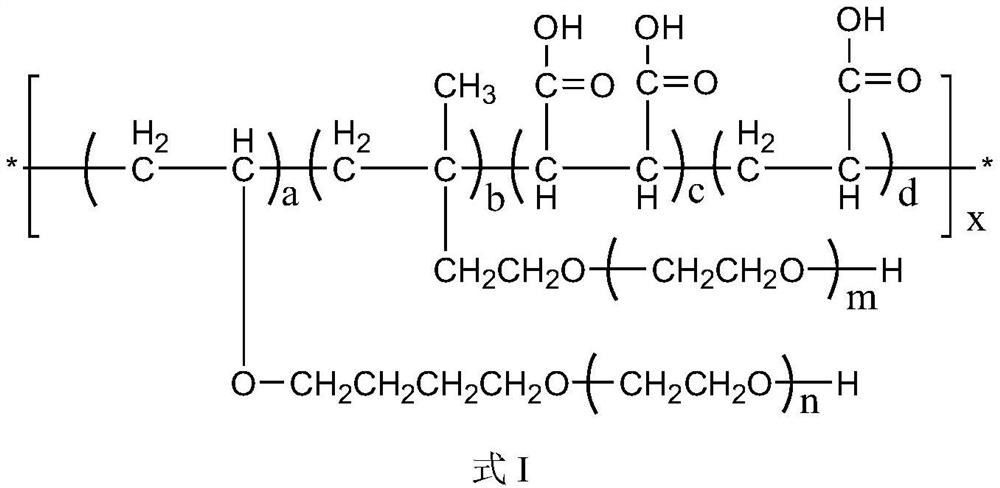

Method used

Image

Examples

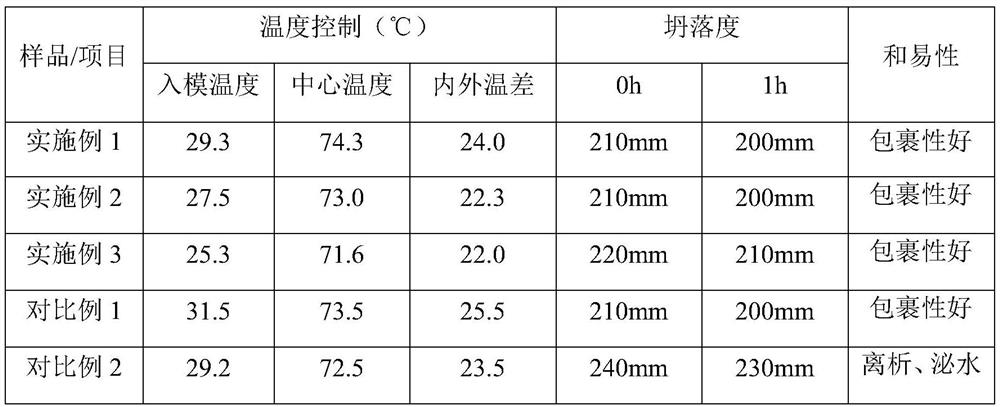

Embodiment 1

[0037] A low heat of hydration high-strength mass concrete for a transfer layer. The raw materials for preparing mass concrete per cubic meter include: 145kg of cement, 270kg of mineral powder, 820kg of sand, 925kg of stone, 125kg of water, 30kg of crushed ice and 9.4 kg (admixture components are: self-made polycarboxylate superplasticizer 6.6kg, sodium gluconate 1.2kg, cellulose ether 1.2kg);

[0038] Its preparation method comprises the following steps:

[0039]Mix and stir stone, sand and 70wt% water for 20s to obtain a wet mixed aggregate, add cement to the wet mixed aggregate and stir evenly to obtain a cement-containing mixture; add remaining Stir water, crushed ice, mineral powder and self-made admixture for 60 seconds to obtain mass concrete; then pour according to the requirements of the slab transfer layer; perform six-sided curing on the pouring transfer layer, store 10cm of water on the upper surface, and place it 20cm above the water cover the film to achieve the...

Embodiment 2

[0041] A kind of low heat of hydration high-strength mass concrete for transfer layer, the preparation raw materials of mass concrete per cubic meter include: cement 83kg, mineral powder 332kg, sand 850kg, stone 900kg, water 100kg, crushed ice 50kg and compound admixture 9.4 kg (admixture components are: self-made polycarboxylate superplasticizer 6kg, sodium gluconate 1.2kg, cellulose ether 2.2kg);

[0042] Its preparation method comprises the following steps:

[0043] Mix and stir stone, sand and 70wt% water for 20s to obtain wet mixed aggregate, add cement to the wet mixed aggregate and stir for 40s to obtain a cement-containing mixture; add remaining Mix water, crushed ice, mineral powder and self-made admixture for 60 seconds to obtain a large-volume concrete mixture, then pour it according to the requirements of the slab transfer layer, perform six-sided curing on the pouring transfer layer, store 10cm of water on the upper surface, and place it on the water The 20cm squ...

Embodiment 3

[0045] A low-heat-of-hydration high-strength mass concrete for a transfer layer. The raw materials for preparing mass concrete per cubic meter include: 130kg of cement, 280kg of mineral powder, 850kg of sand, 900kg of stone, 120kg of water, 40kg of crushed ice and 8.4 kg (admixture components are: self-made polycarboxylate superplasticizer 6kg, sodium gluconate 1.2kg, cellulose ether 1.2kg);

[0046] Its preparation method comprises the following steps:

[0047] Place 10kg of crushed ice on the aggregate conveyor belt to lower the temperature of the aggregate, then mix and stir stone, sand, 10kg of crushed ice and 70wt% water for 20 seconds to obtain wet mixed aggregate, and add cement to the wet mixed aggregate Stir for 40s to obtain a cement-containing mixture; add remaining water, crushed ice, mineral powder and self-made admixtures to the cement-containing mixture and stir for 60s to obtain large-volume concrete, and then pour according to the requirements of the slab tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com