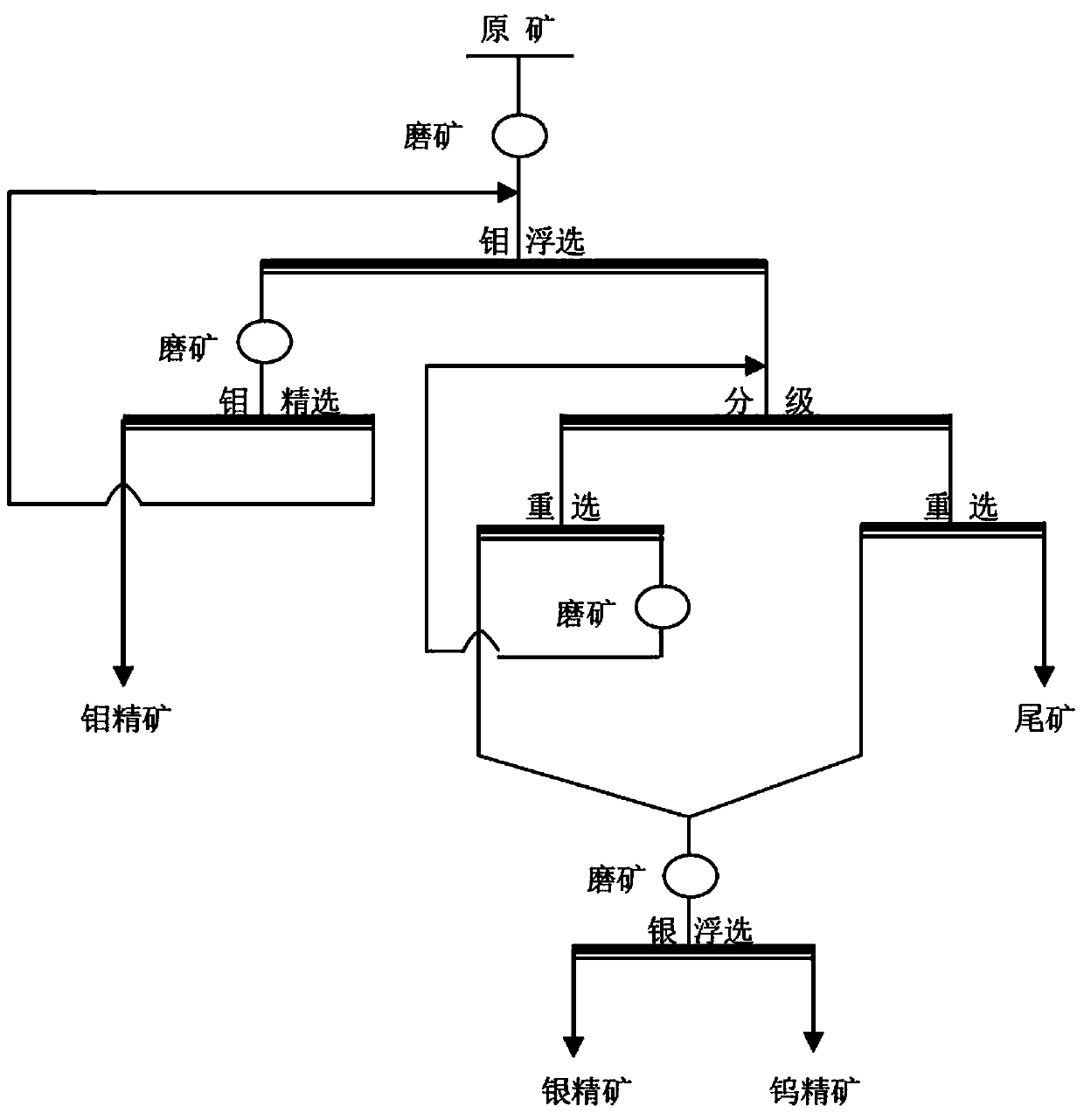

Tungsten-molybdenum-silver multi-metal ore beneficiation process

A polymetallic ore and polymetallic technology, which is applied in the field of beneficiation process for processing tungsten-molybdenum-silver polymetallic ore, can solve the problems of low recovery rate and difficult recovery of wolframite, so as to reduce consumption, improve comprehensive utilization rate and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The processed ore raw ore contains WO 3 0.323%, Mo 0.088%, Ag 67.20g / t. After the raw ore is ground (-0.075mm 60% to 65%), the molybdenum rough concentrate is obtained by flotation; the molybdenum rough concentrate is re-grinded (-0.038mm 85% to 90%) and then selected. Using kerosene as the molybdenite collector, the molybdenum concentrate contains 47.58% molybdenum after one roughing, four times of beneficiation, and two times of sweeping, and the molybdenum recovery rate is 85.43%; the flotation tailings are divided into +0.4mm and - Two grades of 0.4mm, +0.4mm use jig re-election to obtain tungsten-silver mixed concentrate 1; jigging tailings are ground to -0.075mm, 70%~80% are returned to high-frequency sieve, and -0.4mm part is re-selected Obtain tungsten-silver mixed concentrate 2, and the equipment is a shaker. The tungsten-silver mixed concentrate 1 and the tungsten-silver mixed concentrate 2 are mixed, and then the silver is flotation, after one stage of gri...

Embodiment 2

[0036] The processed ore raw ore contains WO 3 0.308%, Mo0.091%, Ag 70.30g / t. After the raw ore is ground (-0.075mm 60% to 65%), the molybdenum rough concentrate is obtained by flotation; the molybdenum rough concentrate is re-grinded (-0.038mm 85% to 90%) and then selected. Using kerosene as the molybdenite collector, the molybdenum concentrate contains 47.62% molybdenum after one roughing, four times of beneficiation, and two times of sweeping, and the molybdenum recovery rate is 85.30%; the flotation tailings are divided into +0.4mm and - Two grades of 0.4mm, +0.4mm use jig re-election to obtain tungsten-silver mixed concentrate 1; jigging tailings are ground to -0.075mm, 70%~80% are returned to high-frequency sieve, and -0.4mm part is re-selected Obtain tungsten-silver mixed concentrate 2, and the equipment is a shaker. The tungsten-silver mixed concentrate 1 and the tungsten-silver mixed concentrate 2 are mixed, and then the silver is flotation, after one stage of grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com