A kind of biomass waste activated carbon and preparation method thereof and application of nitrophenol compounds in the treatment of wastewater

A technology of biomass waste and activated carbon, which is applied in the field of activated carbon, can solve the problems of low carbon production rate of activated carbon, utilization rate of no more than 50%, and low adsorption capacity of activated carbon, and achieve stable performance, more recycling times, and increased adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

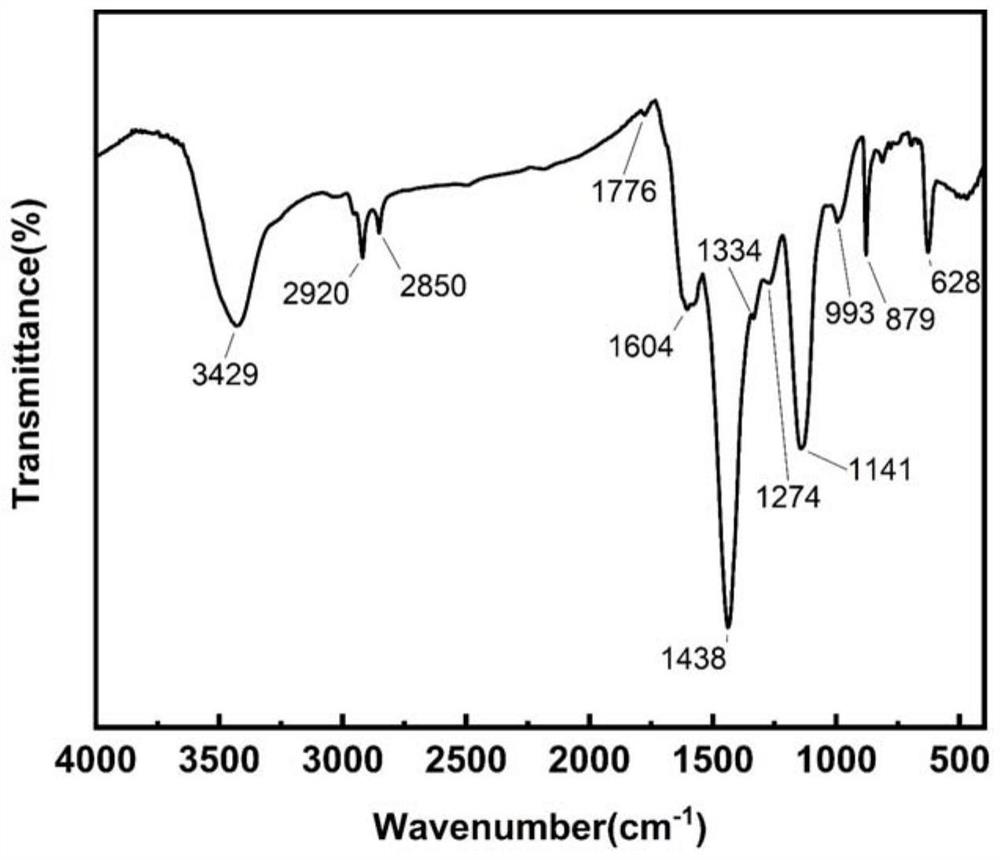

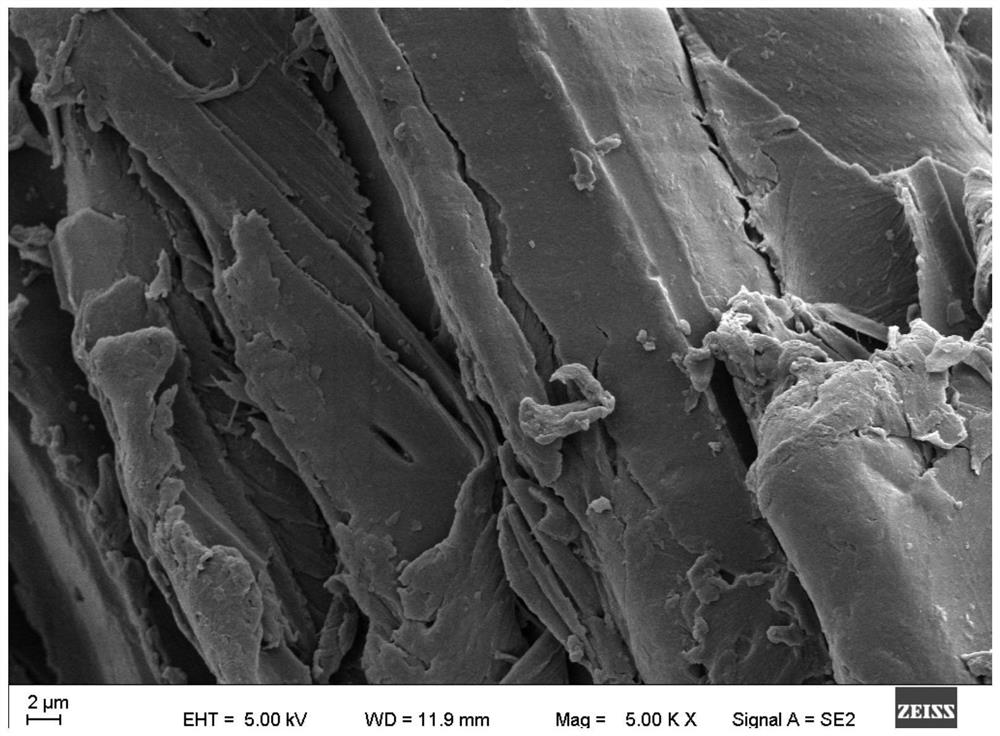

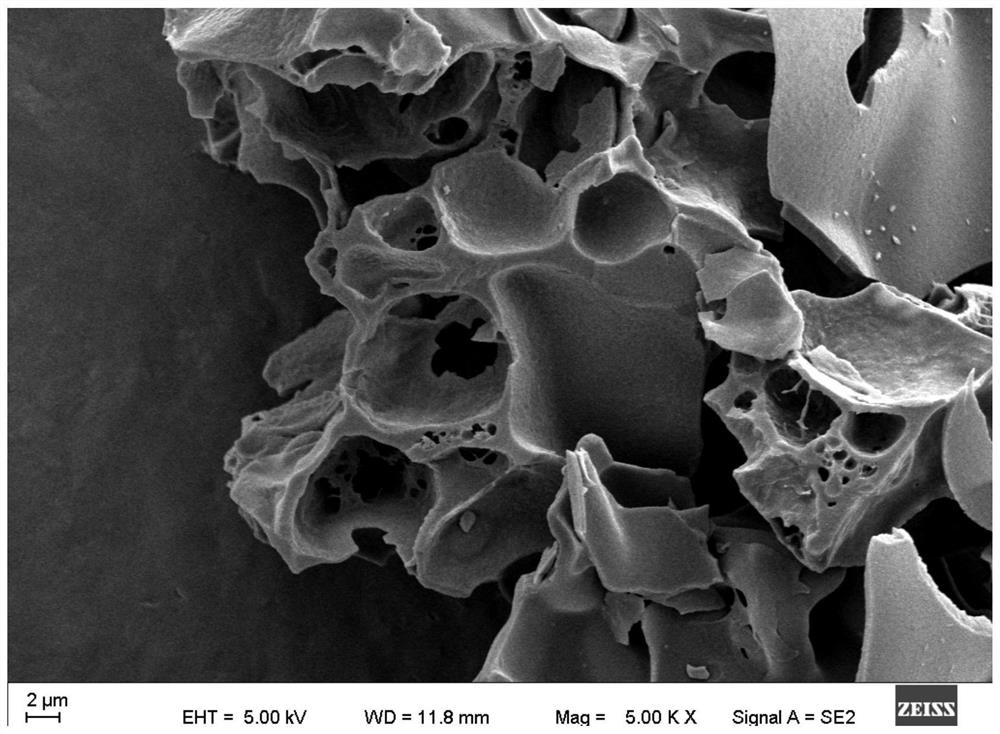

[0040] Preparation of porous activated carbon material: Superfinely pulverize corn stalks until the D90 is greater than 2500 mesh, weigh 100g and put it into a 500ml flask, add 300g of distilled water, heat activate at 150°C for 15h, then cool to room temperature, add initiators successively Potassium sulfate 0.5g and 125g 2-acrylamido-2-methyl-1-propanesulfonic acid were pre-reacted under nitrogen atmosphere at 80°C for 1h, the reaction mixture was frozen in liquid nitrogen, and then 0.05g N,N-methylenebis Acrylamide is used as a cross-linking agent, degassed more than 10 times, slowly heated to 70°C under nitrogen protection, and kept at this temperature for more than 10 hours. After the reaction, the obtained polymer sample was pulverized to 2-3 mm particles and dried. Take 100g of the dried sample, place it in 500mL of 10% sodium bicarbonate solution and let it stand for more than 24h, filter the product, ventilate and dry, put the dried sample treated with sodium bicarbon...

Embodiment 2

[0052] Preparation of porous activated carbon material: Superfinely pulverize corn stalks until the D90 is greater than 2500 mesh, weigh 100 g and put it into a 500 ml flask, add 300 g of distilled water, heat activate at 100 ° C for 20 h, then cool to room temperature, add initiators in sequence Potassium sulfate 0.1g and 50g 2-acrylamido-2-methyl-1-propanesulfonic acid were pre-reacted under nitrogen atmosphere at 70°C for 1.5h, the reaction mixture was frozen in liquid nitrogen, and then 0.01g N,N-methylene was added Bisacrylamide was used as a cross-linking agent, degassed more than 10 times, under the protection of nitrogen, slowly heated to 80°C, and kept at this temperature for 15h. After the reaction, the obtained polymer sample was pulverized to 2-3 mm particles and dried. Take the dried sample 100g, place it in 500mL 5% sodium bicarbonate solution and let it stand for 30h, filter the product, ventilate and dry, put the dried sample treated with sodium bicarbonate in ...

Embodiment 3

[0054] Preparation of porous activated carbon material: Superfinely pulverize corn stalks until the D90 is greater than 2500 mesh, weigh 100 g and put it into a 500 ml flask, add 300 g of distilled water, heat activate at 170 °C for 10 h, then cool to room temperature, add initiators successively Potassium sulfate 1g and 250g 2-acrylamido-2-methyl-1-propanesulfonic acid were pre-reacted under a nitrogen atmosphere at 90°C for 0.5h, the reaction mixture was frozen in liquid nitrogen, and then 0.1g N,N-methylenebis Acrylamide was used as a cross-linking agent, degassed more than 10 times, under the protection of nitrogen, slowly heated to 50 ° C, and kept at this temperature for 8 hours. After the reaction, the obtained polymer sample was pulverized to 2-3 mm particles and dried. Take the dried sample 100g, place it in 500mL 20% sodium bicarbonate solution and let it stand for 15h, filter the product, ventilate and dry, put the dried sample treated by sodium bicarbonate into a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com