Refrigeration device and refrigeration device operation method

A refrigeration device and operating method technology, applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of reduced heat exchange rate, decreased refrigeration capacity of refrigeration devices, and greater impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

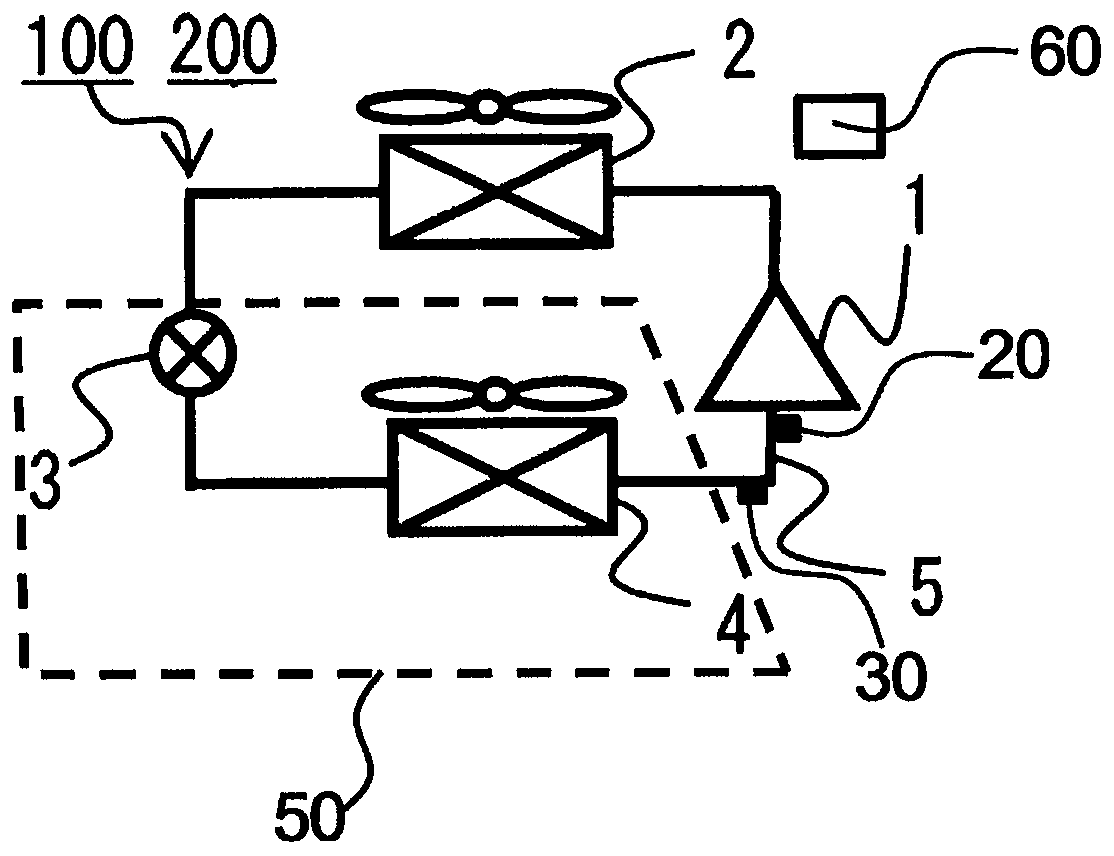

[0018] figure 1 It is a schematic diagram showing the overall configuration of the refrigeration device 100 according to Embodiment 1 of the present invention. In addition, the same code|symbol is attached|subjected to the same part or a corresponding part in each figure. Such as figure 1 As shown, the refrigeration device 100 according to Embodiment 1 is formed by sequentially connecting the compressor 1 , the condenser 2 , the decompression device 3 , and the evaporator 4 through the refrigerant piping 5 . The refrigeration device 100 has a refrigeration cycle in which a refrigerant circulates in the order of the compressor 1 , the condenser 2 , the decompression device 3 , the evaporator 4 , and the compressor 1 . The control unit 60 controls each device constituting the refrigeration device 100 .

[0019] (compressor 1)

[0020] The compressor 1 sucks in refrigerant, compresses it into a high-temperature and high-pressure gas state, and discharges it. For example, the...

Embodiment approach 2

[0065] The refrigeration device 100 according to the second embodiment is different from the refrigeration device 100 according to the first embodiment in that the composition of the refrigerant circulating in the refrigeration device 100 is limited. In Embodiment 2, description will be made focusing on changes from Embodiment 1. FIG.

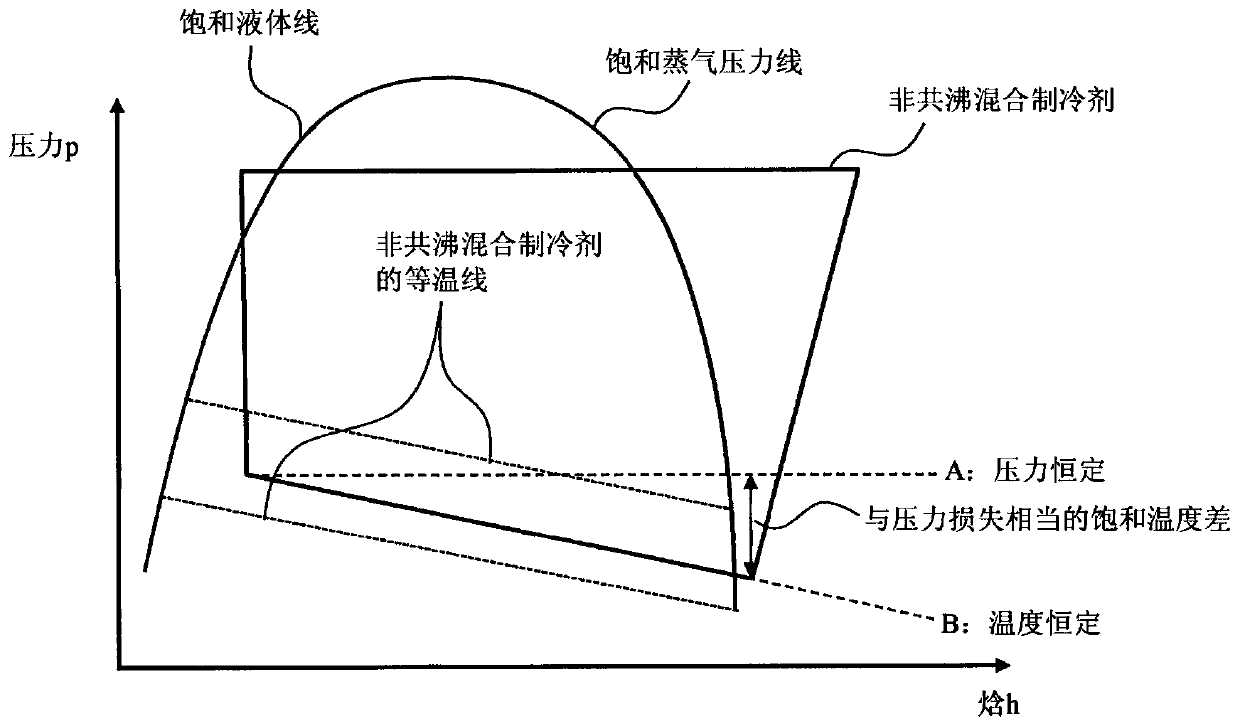

[0066] The zeotropic mixed refrigerant circulating in the refrigeration device 100 of Embodiment 2 is a mixed refrigerant of R32, R125, R134a, R1234yf, and carbon dioxide, and the ratio of R32 is X R32 36wt%, the proportion of R125 X R125 30wt%, R134a ratio X R134a 14wt%, the proportion of R1234yf X R1234yf 14wt%, the proportion of carbon dioxide X co2 is 6wt%. The following effects can be obtained by using such a refrigerant.

[0067]First, although each single refrigerant has physical properties that are advantages or disadvantages, by mixing a plurality of refrigerants, the disadvantages can be reduced and the advantages can be increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com