Apparatus for spinning yarn and method for heating same

A technology of heating chamber and metering device is applied in the field of spinning device, which can solve the problems of uneven temperature distribution and achieve the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

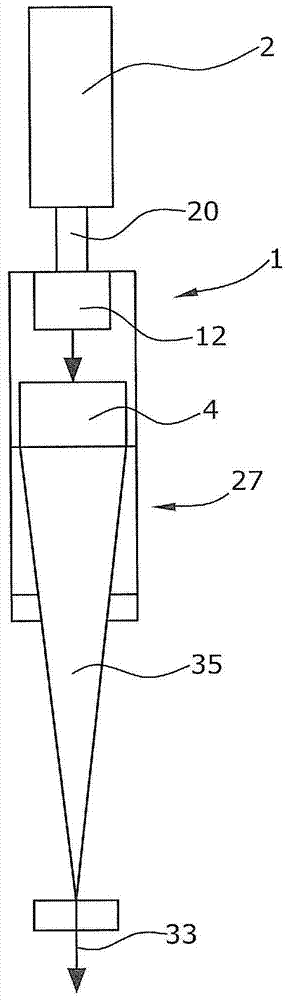

[0038] figure 1 A device 1 for spinning yarn is schematically shown. The melt is melted in the melting device 2 and supplied to the metering device 12 via a melt supply line 20 . The melt from the metering device is forced through spinning nozzles arranged in the nozzle package 4 and drawn off in the form of filaments or fibers 35 . After leaving the spinning nozzle, the filaments are cooled, for example by air, in a blow-on shaft 27 and the cooled fibers 33 are then wound on drums or placed in containers. The filaments can be withdrawn directly or at least after a period of time in a withdrawal device not shown here. The melting device 2, the melt supply line 20 and the metering device 12 are part of the melt supply device. The nozzle package is a holder for the spinning nozzle.

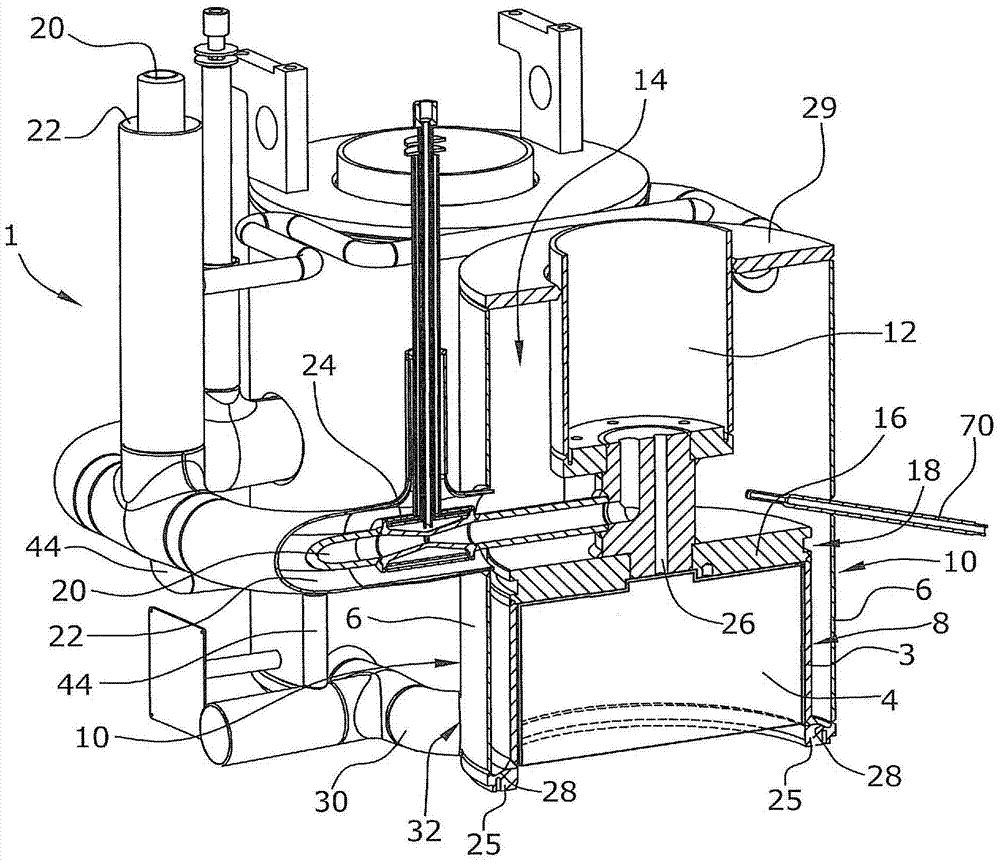

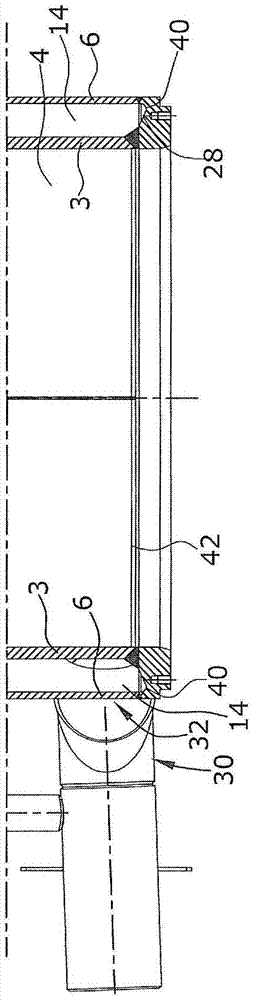

[0039] figure 2 is a detail showing a part of the device 1 for spinning thread. The melting device 2 is not shown, nor is the blowing shaft 27 shown. A nozzle package 4 with at least one spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com