Electric wire and cable manufacturing equipment

A wire and cable manufacturing equipment technology, applied in the field of wire and cable manufacturing equipment, can solve the problems of not having the ability to process multi-wire wires and cables, and the length of the detected line cannot be adjusted, so as to achieve reliable connection, convenient detection and maintenance, and low implementation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

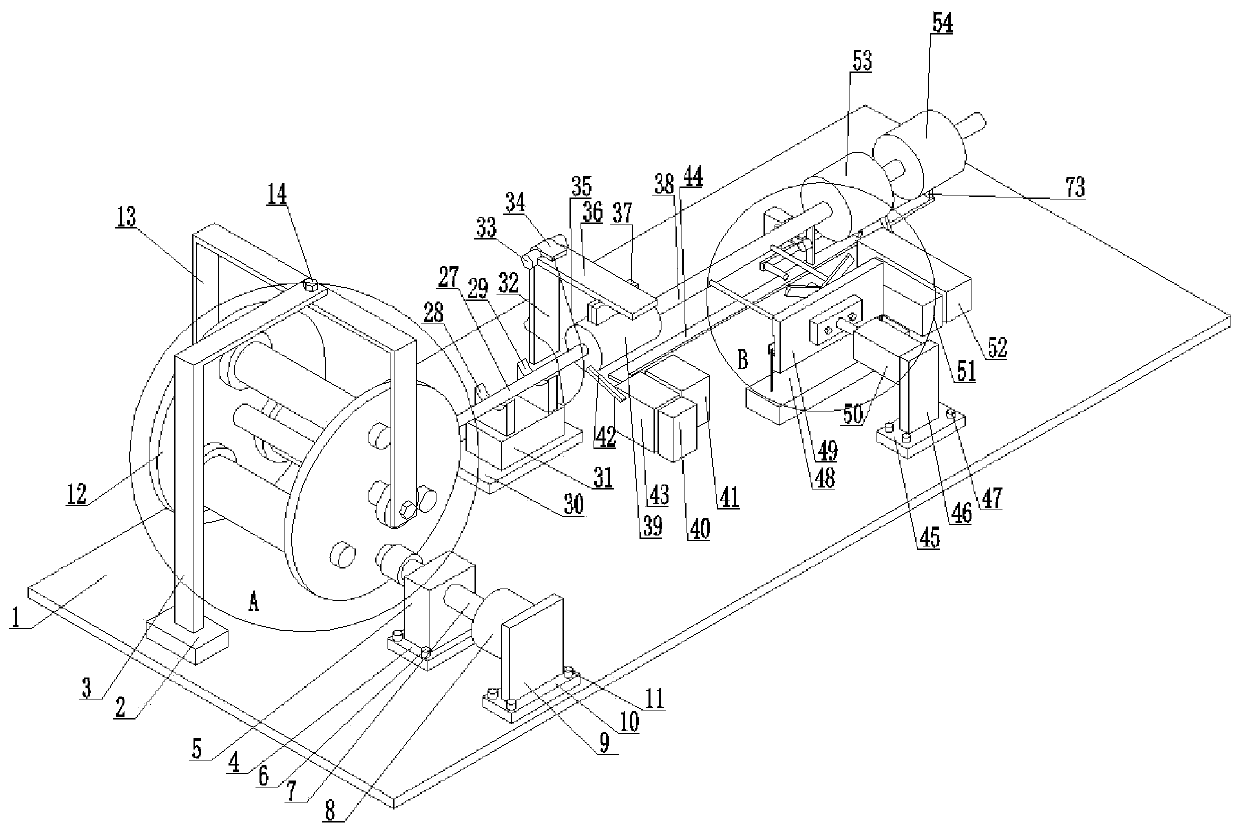

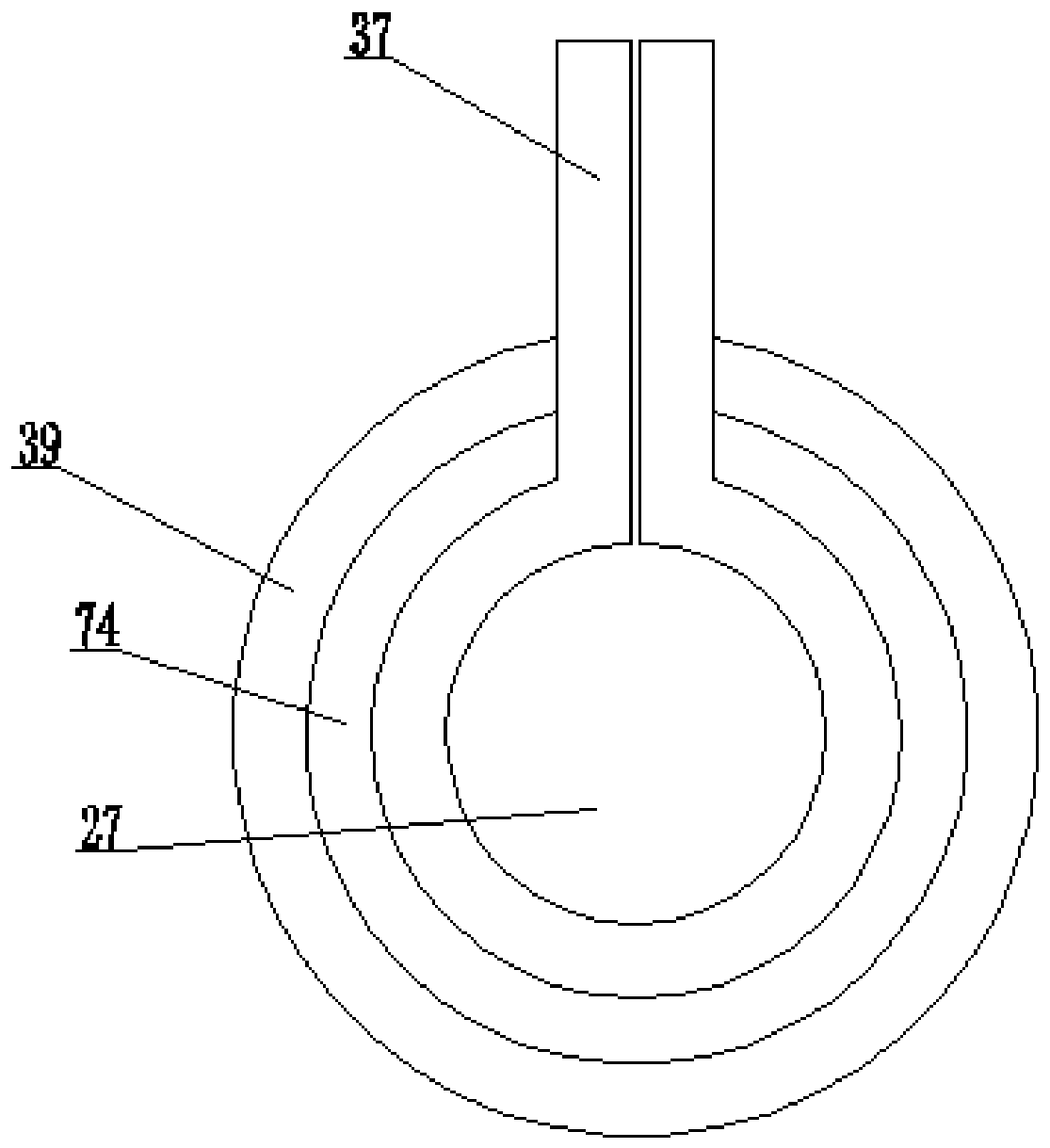

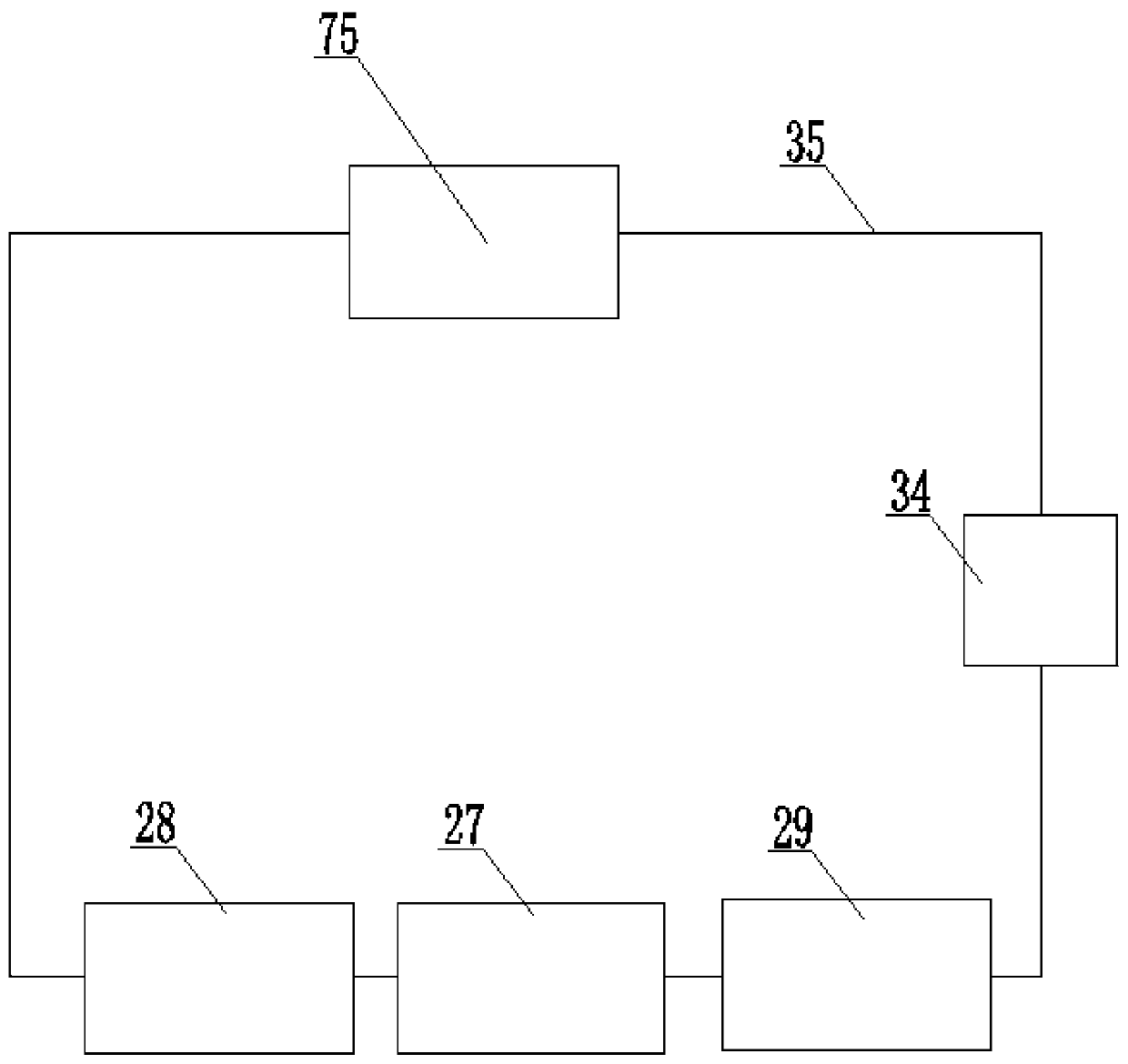

[0027] refer to Figure 1 to Figure 8 A wire and cable manufacturing equipment provided by the present invention includes a base plate 1, a wire core 27, an adaptive control box 31, a wire and cable 38, a limiting plate 49, and an action box 65, and the upper surface of the base plate 1 is provided with a supporting sheet 2. The first bottom sheet 4, the second bottom sheet 10, the fourth bottom sheet 45, the top of the support sheet 2 is fixedly connected with the bottom end of the first bracket 3 by welding, the top of the first bracket 3 is connected with the second bottom The top of the bracket 13 is connected and fixed by the first bolt 14, and the bottom of the front and rear ends of the second bracket 13 is fixed with a bearing 82 through the third series of bolt groups 26, and the inner surface of the bearing 82 is connected to the end of the central shaft 16 In coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com