Cement grinding mill system power consumption index prediction method based on XGBoost

A prediction method and technology of cement grinding, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as the lag of cement grinding system, achieve fast calculation speed, prevent overfitting, and realize the effect of online prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with embodiment the present invention is described in further detail:

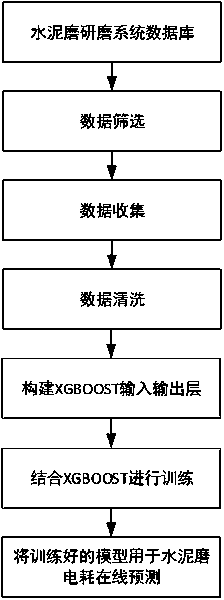

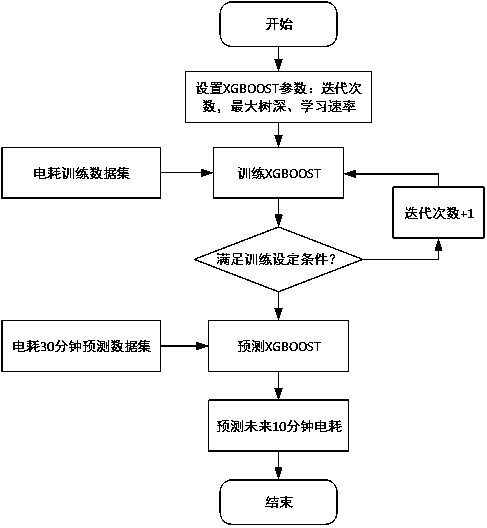

[0056] The present invention proposes an XGBoost-based prediction method for the power consumption index of the cement mill system. First, eight variables related to the power consumption of the cement mill are selected, and OPC technology is used to collect the required variable data, and the artificial experience removal method and the 3σ criterion are adopted. Remove the abnormal data, construct the input and output layers of the XGBoost model, initialize the weight parameters according to the sample data, train the first tree according to the weight, update the weight parameters according to the objective function after training, and conduct a new round of decision tree training. When the sample weight and When it is less than the set threshold or the number of iterations reaches the set value, stop building trees, complete the XGBoost model training, and substitute the indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com