Laboratory hazardous chemical reagent warehouse-in and warehouse-out intelligent management and control system and method

A management and control system and technology of hazardous chemicals, applied in the field of management of chemical reagents in and out of the laboratory, can solve problems such as unsatisfactory, ungiven warehousing operation control plan, and ungiven, so as to avoid purchase volume and avoid chemical Effects of accidents and chemical secondary injury events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

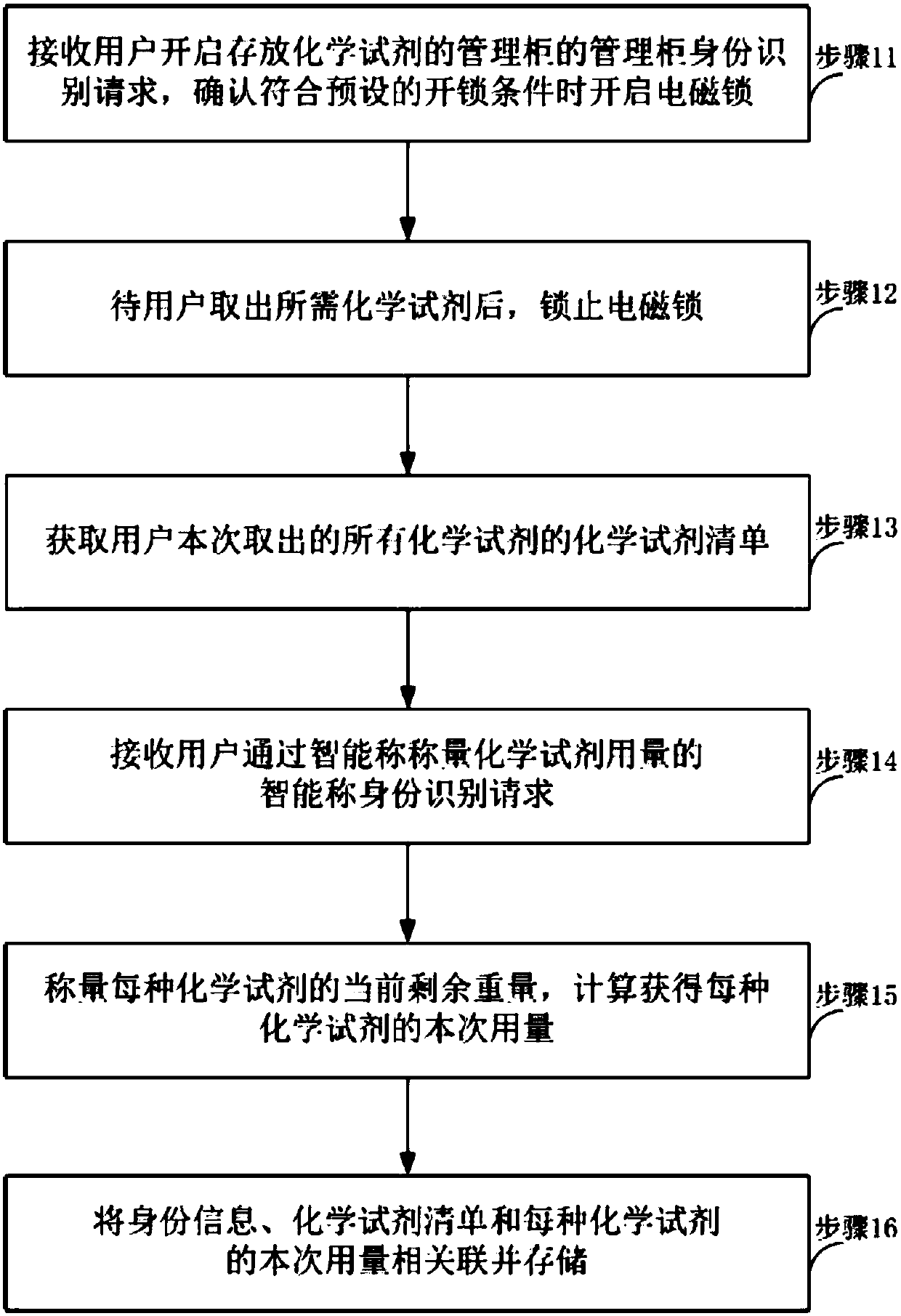

Method used

Image

Examples

Embodiment 1

[0061] According to the electronic inventory ledger of hazardous chemical reagents, it is convenient to check the inventory status of various hazardous chemical reagents.

[0062] Inventory amount < actual amount - last inventory amount, the difference is the outbound amount;

[0063] According to the database of hazardous chemicals, it is easy to check the outbound situation. Table 1 lists the outbound quantities, outbound time, operators and other detailed information of sulfuric acid, hydrochloric acid, nitric acid, toluene, and methyl ethyl ketone.

[0064] Table 1 Hazardous chemical reagents out of the warehouse

[0065]

[0066]

Embodiment 2

[0068] According to the electronic inventory ledger of hazardous chemical reagents, it is convenient to check the inventory status of various hazardous chemical reagents.

[0069] Inventory quantity > actual quantity - the last time the inventory quantity was stock-in, and its increment is the stock-in quantity;

[0070] According to the database of hazardous chemicals, it is easy to check the storage situation. Table 1 lists the detailed information such as sulfuric acid, hydrochloric acid, nitric acid, toluene, butanone, storage quantity, storage time, and operators.

[0071] Table 2 Hazardous chemical reagent storage situation

[0072]

Embodiment 3

[0074] According to the barcode of each chemical reagent, you can quickly check the entry and exit status of the chemical reagent library for such hazardous chemicals, the information on requisition, and the chemical reagents and MSDS instructions for such hazardous chemicals in the database, which greatly improves the speed of information query.

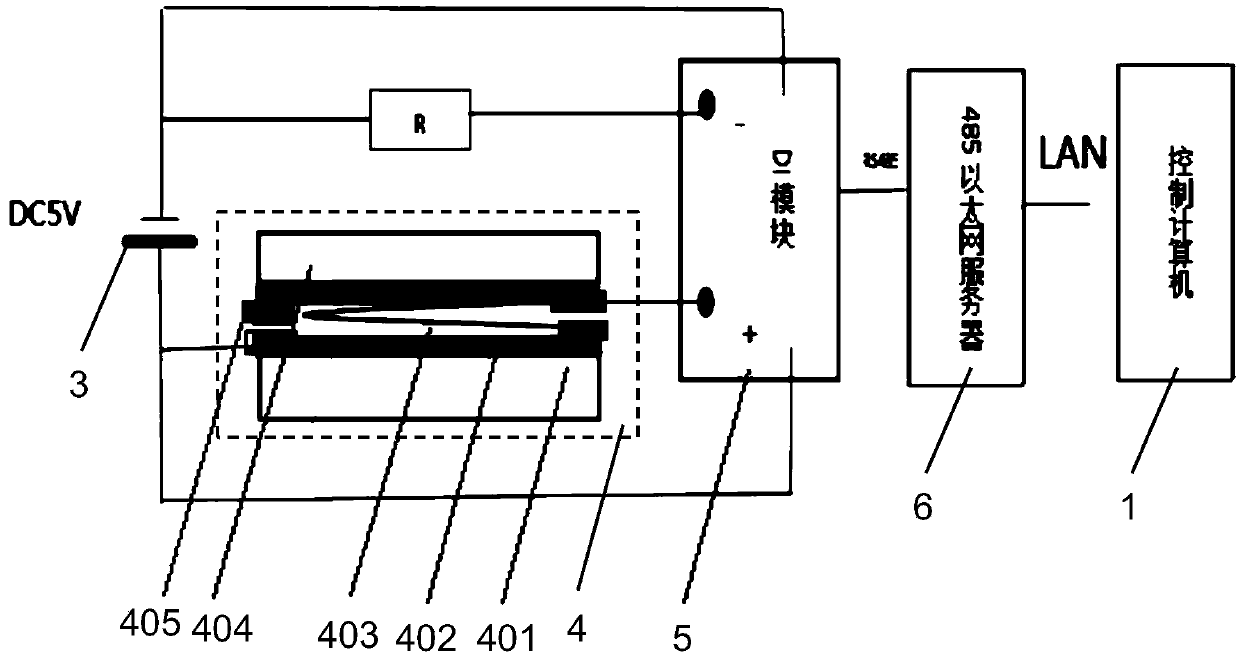

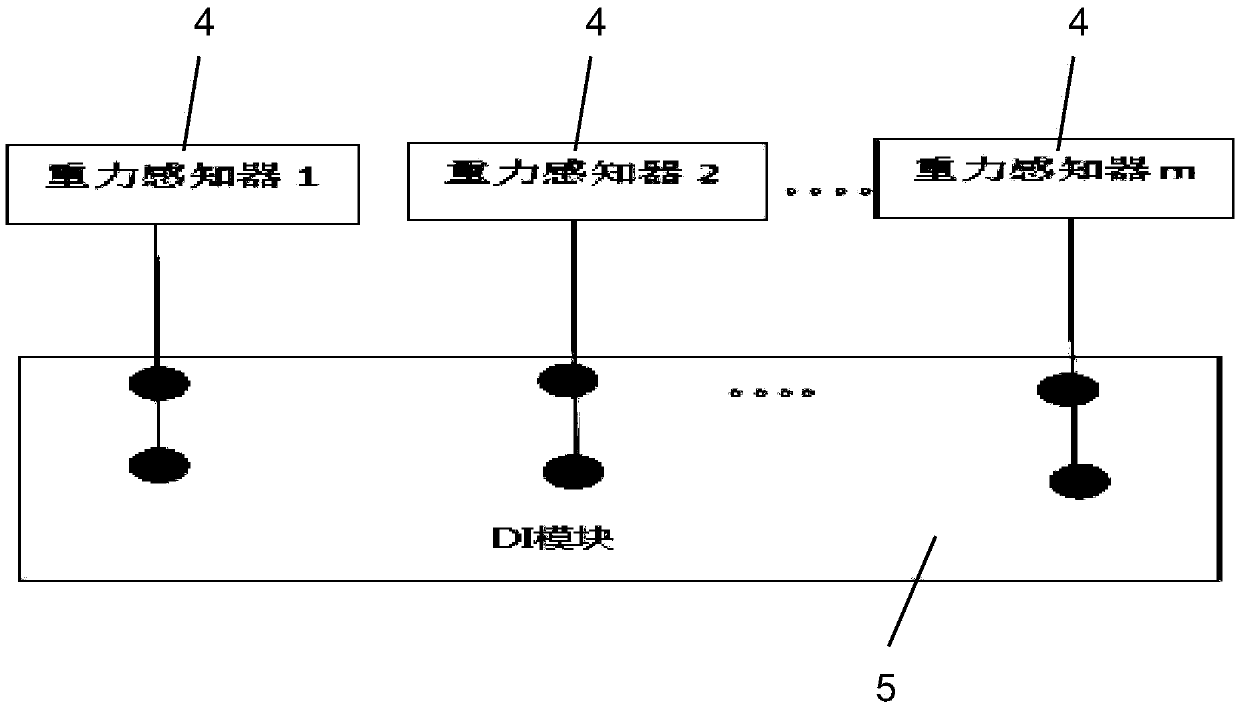

[0075] To sum up, the present invention uses the chemical reagent bottle as the most basic unit of measurement, and the gravity sensor perceives the "presence" and "absence" of chemical reagents to obtain the current warehouse inventory of hazardous chemicals chemical reagents. In addition, through the serial port number of the classmate module and The address is associated with the chemical reagent name of the hazardous chemical and combined with the fingerprint identification system, by periodically polling each communication module, real-time control of how many bottles of a certain hazardous chemical a specific person receives or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com